FengChi Product Category

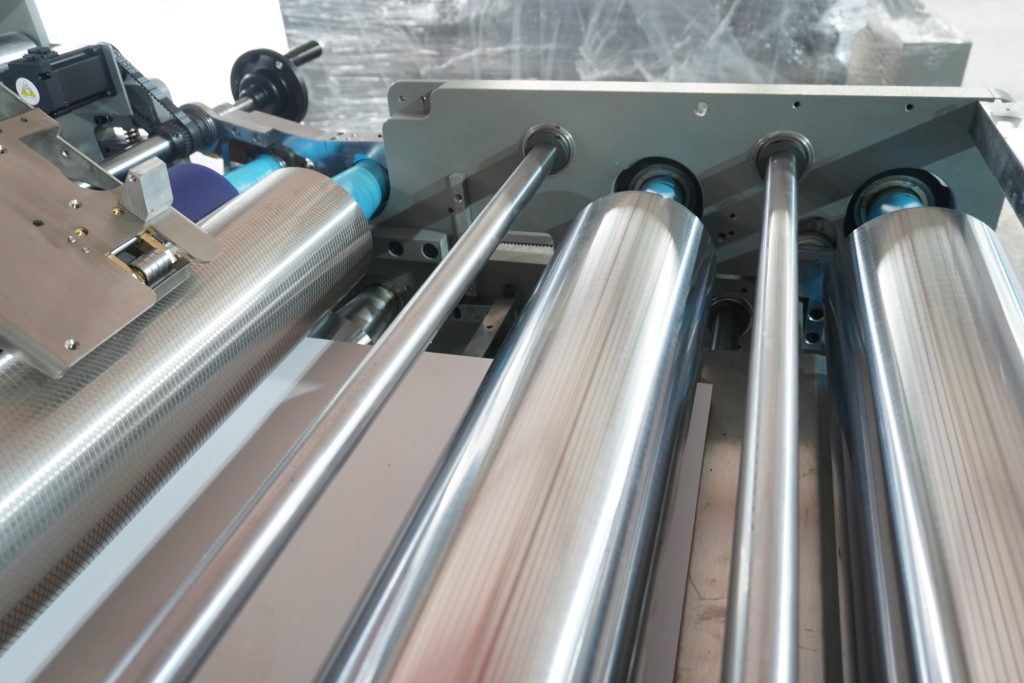

Automatic high speed big laminating machine

Product

Automatic high speed big laminating machine

Brand: FENGCHI

Certification: CE, ISO9001

- Origin: China

- Minimum order quantity: 1PC

- Price: TBA

- Payment terms: T/T, D/P, L/C

- Supply capacity: Monthly 50 flux lamators+20 stackers

- Delivery deadline: around 20 days (7 days for urgent order)

GE-1450L Automatic high speed big laminating machine

Model NO.: GE-1450L

Automatic Grade: Automatic

Performance: Adjustable

Patent: Patented Kinetic Energy Recovery System

Max. Speed: Adjustable

Advantages: Low Failure Rate, Safe, Efficiency, Long Life

After-sales Service: Maintenance-Free Automatic Refueling System

Warranty: Not specified.

Explore our more automatic big laminating machine

Are you interested in our product?

Product Highlights

2.Whole pallet loading: adopt the whole pallet loading design to save the manpower and time. After the pallet is loaded against the gear gauge, aligning the zero position to make left and right adjustment

3.Separate manual stacking: when the platform descend, manual stack the paper on the pallet

2.10 limits and protective sensors, real-time detection and adjustment to ensure safety production

3.Industry Initiative of servo control lifting platform, single sheet lifting same as offset printing press, without wear, and can be set as from 1~50 sheet/lifting.

2.the correction system of paper feeding ensure the high speed feeding smoothly without any skew

3.The sheet delivery stopper make sure the single sheet feeding, optional to upgrade by adding double sheet detection system

4.Becker vacuum pump with large suction, strong blowing, good stability and durable

1) Industry Initiative of leading edge bottom feeder, suitable for a variety of warped deformation, rough and heavy bottom board feeding 2)Unidirectional rotation feeding roller, without wear, life cycle up to 10 years 3)Standard equipped with right cylinder to pile up the paper in neat, available to adjust in a whole or on the right side, greatly saving manpower. 4)Patented non-stop suction with 5.5KW power, air flow adjustable at will

2.Belt bottom feeder,Extra heavy wear-resistant belt, suitable for cardboard/flute laminating, without scratch in conveying

Models | GE-1450L |

Max. paper size | W 1450mm * L 1450mm |

Min. paper size | W 360mm * L 360mm |

Bottom Paper Sheet Thickness | 0.3 -10mm |

Upper Paper Sheet Thickness | 120 g-700 g |

Max. Working Speed | 13000PCS/H (153M/Min) |

Laminating Accuracy | ±1.0mm Standard Sheet Paper |

Applicable Glue | Resin adhesive, starch glue and etc. (PH6~8 will be suitable for laminating glue) |

Machine Weight |

|

Dimension (LxWxH) | L 15400mm * W2300mm *H 2550mm |

Power Supply | 380VAC/4P |

Power | 20KW |

Applicable Corrugated Board | Laminating of A, B, E, F, double corrugated paper and other flat corrugated papers |

Our Advantages

WHY CHOOSELAMINATOR MACHINES

SERVO VACUUM PAPER FEEDING

Unique servo vacuum paper feedingmechanism, easier feeding thanother laminator machines.

SERVO TRACKING SYSTEM

Automatic servo trackingsystem,ensure lamination accuracy

DIGITAL GLUE ADJUSTMENT

Automatic digital glue adjustment,bottom paper height adjustment system

AUTOMATIC REFUELING SYSTEM

Double bearing automatic refuelingsystem,maintenance free

Have a project, need a helping hand?

What do we do

Why choose us to cooperate?

2. Strong R&D team by 25 senior engineers over 30 years experience in printing industry. With 30 patents to ensure product more stable, more efficient and durable.

3. After-sale service and technical assistance: company provides after sales service and technical assistance as per customers’ requirement and needs with response within 24 hours.

4.Cost saving: Full servo digital operating system greatly reduce operator level(normally two primary operator) with manpower saving, 150mm roller with double bearing and auto refueling system make equipment durable and free maintenance. China highest laminating speed at 16,000pcs/hour.

Are you a manufacturer?

Yes, we are paper Laminator master from China over 13 years, specialize in paper flute laminator and paper pile turning machines.

Do you have stock products to sell?

We produce machines in bacth normally. So most models we have some in stock, please check with us before ordering.

How about warranty?

Warranty period: 12 months from the shipping date of machine. Warranty will be not valid if machine subject to misuse or accidental damage or operator’s error. During the valid time, we will supply spare parts. If you have any other questions, pls contact us and we will reply you through product’s photos and videos to make every detail clear. We also provide all lifetime warranty with paid service.

Do you test all your goods before delivery?

How about installation and training?

Warranty period: 12 months from the shipping date of machine. Warranty will be not valid if machine subject to misuse or accidental damage or operator’s error. During the valid time, we will supply spare parts. If you have any other questions, pls contact us and we will reply you through product’s photos and videos to make every detail clear. We also provide all lifetime warranty with paid service.

What is your delivery time?

Our delivery time is 10-30 working days after receiving full payment or deposit. The specific delivery time depends on the product and the order quantity.

What are your packaging conditions?

Usually, we pack the machine in a container with a plastic bag with desiccants, then with strong seaworthy wooden cases. Each machine will be protected by anti-rusted oil before put into case.

Will you supply for OEM orders?

Are you interested in our product?

Contact us

TEL