Automatic Folder Gluer

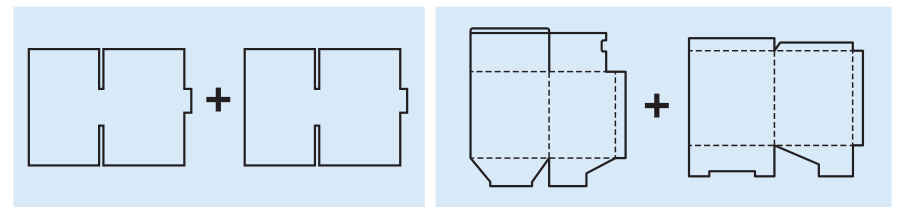

High-speed automatic folding and gluing, suitable for

the production of double-piece or single-piece corrugated boxes.

Automatic Folder Gluer

Achieve high-speed, precision folding and gluing for your corrugated box production.

Key Features & Benefits

Our automatic folder gluer is engineered for maximum efficiency, precision, and reliability in your corrugated box production.

High Speed

Achieve gluing speeds of over 2,500 sheets per hour for maximum productivity.

High Accuracy

Motion-control servo positioning system guarantees ±1.0 mm registration accuracy with automatic digital adjustments.

Strong Cohesiveness

Hot-glue for positioning works with cold glue cementing. Internal pressure of the vacuum drum ensures automatic cold gluing.

One-Man Operation

Professional delivery line mechanism, one-man operation to save the labor cost.

Full Automation

16 servo motors control all key parameters. Enjoy one-key operation for effortless setup and adjustments.

Short Set-up Times

Reduce changeover times with intuitive controls and preset configurations for different box styles.

Applications

This high-speed automatic folder-gluer machine is specially designed for gluing and folding double-piece or single-piece corrugated boxes.

See It In Action

Watch how our automatic folder gluer machine transforms corrugated board into perfectly folded and glued corrugated boxes at high speed.

Choose Your Model

FC-2300Z Automatic Folder Gluer Machine

Usage: Sticky carton box

Material: Steel

Feeding Type: Automatic

Feeding Way: Automatic Feeding

Applicable Industries: Package

Glue: Water-base cold glue

Automatic Grade: Semi-Automatic

Max Paper Thickness: 1 – 12 mm

Processing Type: Paper making machine

Driven Type: Gluing Machine, Electric

Electrics Brand: Schneider / MCGS / CHINT / DELTA

Raw Material: Paper

Power Of Motor: Adjustable-speed Motor

Glue Material: Cold glue

Dimensions: 2.1 * 0.5 * 1 mm

FC-2600Z Automatic Folder Gluer Machine

Usage: Sticky carton box

Material: Steel

Feeding Type: Automatic

Feeding Way: Automatic Feeding

Applicable Industries: Package

Glue: Water-base cold glue

Automatic Grade: Semi-Automatic

Max Paper Thickness: 1 – 12 mm

Processing Type: Paper making machine

Driven Type: Gluing Machine, Electric

Electrics Brand: Schneider / MCGS / CHINT / DELTA

Raw Material: Paper

Power Of Motor: Adjustable-speed Motor

Glue Material: Cold glue

Dimensions: 2.1 * 0.5 * 1 mm

FC-3000Z Automatic Folder Gluer Machine

Usage: Sticky carton box

Material: Steel

Feeding Type: Automatic

Feeding Way: Automatic Feeding

Applicable Industries: Package

Glue: Water-base cold glue

Automatic Grade: Semi-Automatic

Max Paper Thickness: 1 – 12 mm

Processing Type: Paper making machine

Driven Type: Gluing Machine, Electric

Electrics Brand: Schneider / MCGS / CHINT / DELTA

Raw Material: Paper

Power Of Motor: Adjustable-speed Motor

Glue Material: Cold glue

Dimensions: 2.1 * 0.5 * 1 mm

* Not sure which automatic folder gluer is best suited to your needs? Contact our experts.

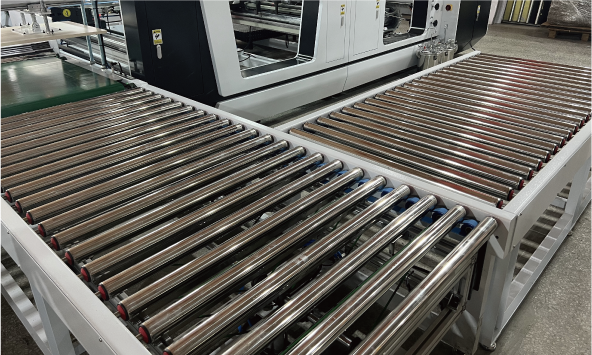

Product Gallery

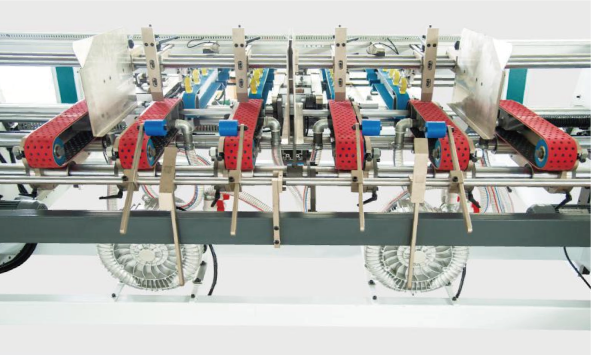

Independent Dual Feeding Mechanism

- Dual suction paper feeding mechanism is independently controlled, providing stable, precise and reliable paper feeding with easy adjustment.

Sheet Delivery Individual Control

- An individual drive structure for AB sheet feeding to avoid scratches.

Alignment System

- A motion-control servo positioning system ensures more accurate carton alignment and faster digital adjustments.

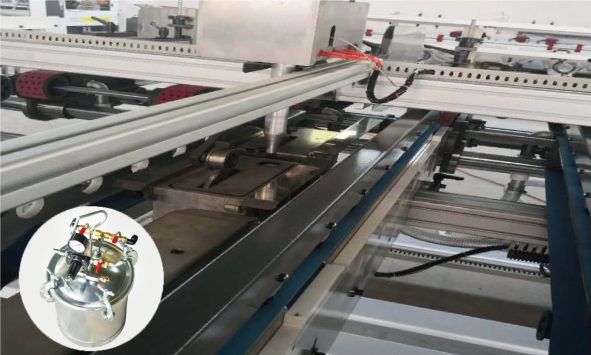

Strong Cohesiveness

- The hot glue is heated by aluminum glue box quickly. Stainless steel bucket stores cold glue to resist corrosion with pressure for automatic gluing.

Special Belt Feeder System

- Equipped with four conveying belts to ensure smooth sheet conveying.

Servo Motor Controls Folding

- Use servo motor to fold the carton, with adjustable pressure and stable folding.

Positioning Devices for Easy Adjustment

- Equipped with front and rear positioning devices, which can be easily adjusted according to different products.

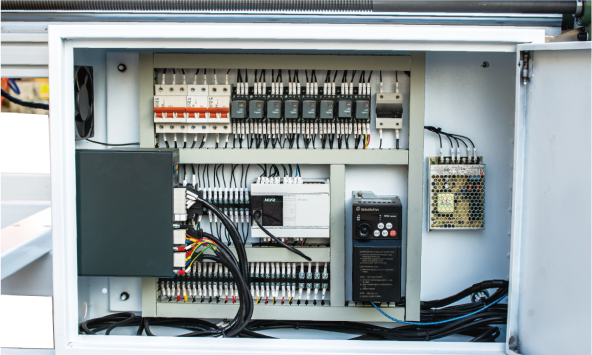

Well-known Brand Electrical Components

- The electrical components are from well-known brands at home and abroad to ensure the normal operation of the machine.

Carton Receiving Line Design

- Professional design enables one-man operation for input and receiving to save the labor cost in production.

Technical Specifications

| Parameter / Model | FC-2300Z | FC-2600Z | FC-3000Z |

|---|---|---|---|

| Maximum Sheet Size (Single) | 1150 x 1150 mm | 1300 x 1150 mm | 1500 x 1200 mm |

| Minimum Sheet Size (Single) | 550 x 350 mm | 550 x 350 mm | 550 x 350 mm |

| Feeding Pile Height | 400 mm | 400 mm | 400 mm |

| Registration Accuracy | ±1.0mm | ±1.0mm | ±1.0mm |

| Sheet Thickness | E flute to 10mm | E flute to 10mm | E flute to 10mm |

| Power | 16 kW | 16 kW | 16 kW |

| Gross Weight | 4.6 T | 5.0 T | 5.4 T |

| Machine Size (Receiving Parts Exclusive) | 4950 x 3300 x 1800 mm | 4950 x 3800 x 1800 mm | 4950 x 4200 x 1800 mm |

* Need a tailored spec? Contact our sales engineers for configuration and site requirements.

Why Partner with Fengchi?

High Quality

Fengchi products are manufactured by a team of skilled and qualified technicians. Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Innovative Solutions

We work with you to find not just one, but the right solution for your packaging production – from stand-alone to turnkey.

Global Support

With three offices around the world, and around 50 agents, we are able to provide local support on a global level.

What Our Customers Say

Hear from packaging professionals who have transformed their production with our equipment.

“Since installing the FC-2300Z Automatic Folder Gluer Machine , our corrugated box production efficiency has increased by 35%. The quick changeover between different box styles has been a game-changer for our operation.”

– Michael Rodriguez, Production Manager

Trusted by Industry Leaders Worldwide

Our Technical Service

After Sales service begins with the arrival of the machinery at the customer’s factory.

To maximize investment whether a single machine or an entire line, the equipment needs to enter the existing production quickly and deliver its contribution. Fengchi offers a dedicated team of technicians that assemble, calibrate and commission the machinery.

Our engineers teach customer operators the machines function, calibration, available options, best practice and scheduled housekeeping.

Fengchi is always available to its customers if they have a problem, concern or malfunctionwith their machinery.

Frequently Asked Questions

What is the maximum speed (sheets/hour)?

Up to 2,500 sheets/hour. Contact us with your target output to verify model suitability.

What box types does it support?

Double-piece (AB) carton lines and various corrugated types. Contact our experts for more details.

How about installation and training?

Normally, one operator can finish intallation in 2 hours with installation manual and video. If purchaser’s engineer travels at own cost to China, free training session. If engineer sent to purchaser’s factory, all travel cost paid by purchaser.

What warranty/support?

Standard 12-month warranty; global spare parts and service available.

Delivery & lead time?

Typical lead time: 10–30 days (confirm per order). The specific delivery time depends on the product and the order quantity.

Will you supply for OEM orders?

Yes, we can customize the production machine according to your requirements.

Tell Us About Your Project

By filling in your information, we will provide you with a personalized quote.