Automatic Cardboard Laminator

Up to 10,000 sheets/hour with ±0.5mm alignment accuracy.

Built for folding carton plants requiring stable, high-volume lamination.

Turnkey solutions • CE Certified • Global Installation • 12-Month Warranty

Automatic Cardboard Laminator

Built for folding carton plants requiring stable, high-volume lamination.

Key Benefits

The fully automatic cardboard laminator designed for folding carton production. Engineered for high output, precision, and low operator workload.

High Output

Laminating up to 10,000 sheets per hour, ideal for high-volume production environments.

High Accuracy

±0.5mm laminating accuracy ensures consistent quality across all paper types and sizes.

Quick Changeovers

Switch between different sheet sizes and jobs in minutes, not hours, maximizing your machine uptime.

Heavy-Duty Construction

Both models feature robust construction with 6,500kg weight for stable, reliable operation.

See It in Action

Watch the automatic cardboard laminator running at high speed in action.

Choose Your Model

Need help finding the right model or custom configuration for your business? Contact sales.

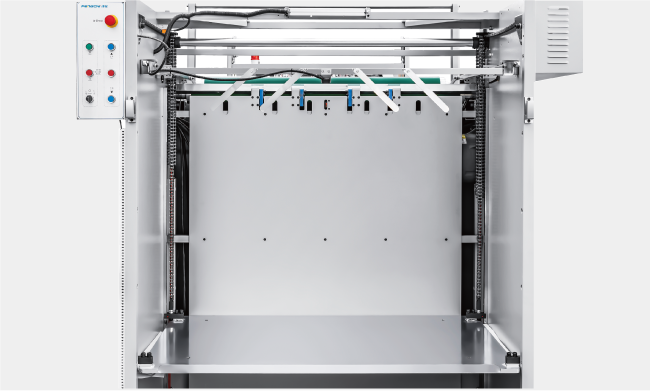

GK-1307 Automatic cardboard laminator

Model: GK-1307

Max Laminating Speed: 10000 sheets/hour

Generators Power: 3KW

Driven Type: Hydraulic

Speed Of Cover: 5-50 pieces/min

Laminating Accuracy: ±0.5mm

Watering Type: Automatic water

Power Consumption: 20kw

Machine Type: Cardboard Laminator

Machine Speed: 105 pcs/min

Max Paper Size: 1300mm * 720mm

Applicable Industries: Manufacturing Plant, Packing industry

Machinery Test Report: Provided

Weight Of Machine: 2500kg

Production Time: 70 days

GK-1310 Automatic cardboard laminator

Model: GK-1310

Max Laminating Speed: 7800 sheets/hour

Generators Power: 3KW

Driven Type: Hydraulic

Speed of Cover: 5-50 pieces/min

Laminating Accuracy: ±0.5mm

Watering Type: Automatic water

Power Consumption: 20kw

Machine Type: Cardboard Laminator

Machine Speed: 105 pcs/min

Max Paper Size: 1300mm * 1000mm

Applicable Industries: Manufacturing Plant, Packing industry

Machinery Test Report: Provided

Weight Of Machine: 2500kg

Production Time: 70 days

Product Gallery

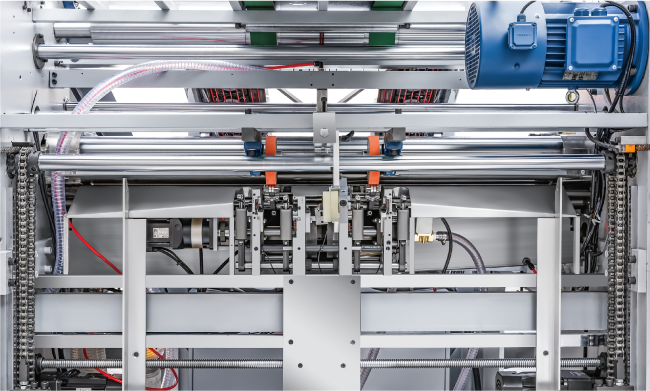

Laminating Part

- The paper lamination alignment adopts differential speed tracking; the top and bottom papers are simultaneously conveyed to the alignment guide, ensuring accurate lamination.

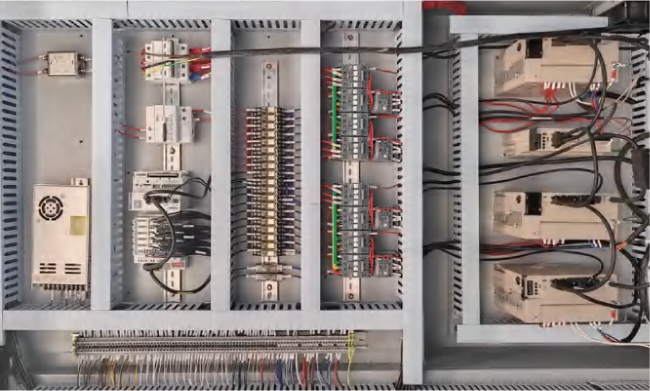

Electric System

- Uses well-known components from both domestic and international brands, designed to meet CE standards, and supports remote control with equipment upgrades.

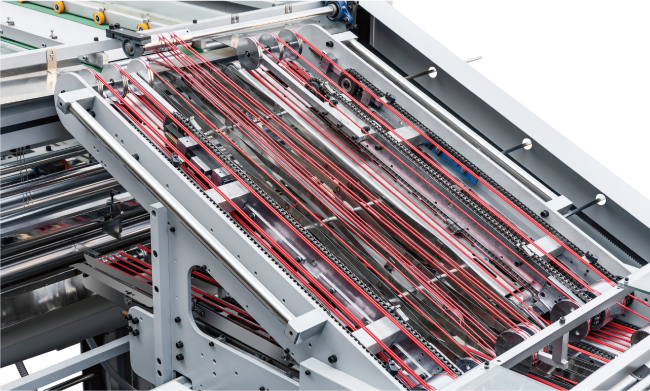

Feeding System

- Uses a 360-degree rotating high-speed front suction servo feeder equipped with a 4.0 kW vacuum pump to ensure faster, more stable paper feeding and smoothly handle both thick and thin papers.

Servo-controlled Stacking System

- Uses a servo control system that allows each lift or drop speed to be freely adjusted, ensuring stable, smooth, and seamless conversion.

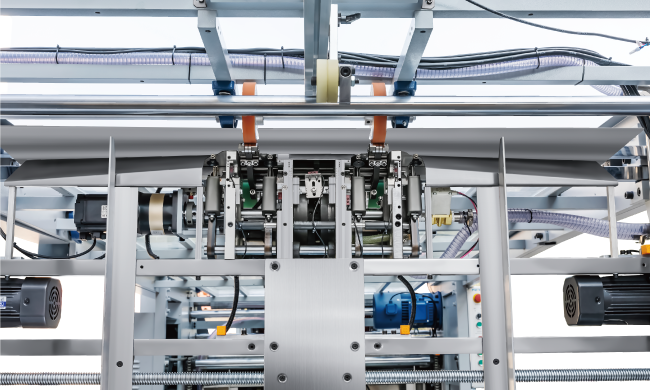

Aligning System

- A full-servo tracking system ensures stability and achieves ±0.2 mm high-precision alignment.

Paper Collecting System

- Laminated paper is automatically stacked and transported via forklift, thereby reducing labor costs by 30% to 50%.

Technical Specifications

| Specification | GK-1307 High Speed | GK-1310 Large Format |

|---|---|---|

| Max Paper Size | 1300 × 720 mm |

1300 × 1000 mm

+280mm

|

| Min Paper Size | 500 × 350 mm | |

| Top Paper Thickness | 100-700 gsm | |

| Bottom Paper Thickness | 200-900 gsm | |

| Max Working Speed | 10,000 Sheets/hour |

7,800 Sheets/hour

-2,200

|

| Laminating Accuracy | ±0.5 mm (Standard Sheet Paper) | |

| Applicable Glue | Starch glue, resin glue, milky glue, etc. (PH value 6-8) | |

| Machine Weight | 6,500 kg | |

| Machine Size | 9900 × 2250 × 2180 mm | |

| Input Voltage | 380 VAC/3P | |

| Power | 20 kw | |

| Applicable Paper | Thin paper, cardboard paper, coated paper, gray board, thick paperboard, and more. | |

* Need a tailored spec? Contact our sales engineers for configuration and site requirements.

Why Partner with Fengchi

High Quality

Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Vast Experience

More than 15 years of experience within automation gives us an enormous know-how and expertise in laminating solutions.

30 + Patents

We continuously push the boundaries of speed and performance, securing 30 patents through independent research and development.

Global Support

We proudly export corrugated laminating solutions worldwide, ensuring international clients benefit from our innovative technology.

What Our Customers Say

See what our customers say about the GK Series automatic cardboard laminator.

“This cardboard laminator transformed our production line. We’ve seen a 40% increase in output and the consistency is unmatched. A game-changer.”

– John Doe, Production Manager

“The quick-change tooling has revolutionized our production line. We can now handle small batch custom orders profitably, which has opened up a whole new market for us.”

– Jane Smith, Operations Director

“The precision of the glue application has eliminated our quality control issues. We’ve seen a 95% reduction in customer complaints about laminate quality.”

– Robert Johnson, Quality Manager

Trusted by Industry Leaders Worldwide

Our Technical Service

After Sales service begins with the arrival of the machinery at the customer’s factory.

To maximize investment whether a single machine or an entire line, the equipment needs to enter the existing production quickly and deliver its contribution. Fengchi offers a dedicated team of technicians that assemble, calibrate and commission the machinery.

Our engineers teach customer operators the machines function, calibration, available options, best practice and scheduled housekeeping.

Fengchi is always available to its customers if they have a problem, concern or malfunctionwith their machinery.

Frequently Asked Questions

What is the lead time?

10–30 working days depending on configuration.

How about installation and training?

Normally, one operator can finish intallation in 2 hours with installation manual and video. If purchaser’s engineer travels at own cost to China, free training session. If engineer sent to purchaser’s factory, all travel cost paid by purchaser.

What materials can be laminated?

Cardboard, coated paper, gray board, thin paperboard, thick paperboard, and more.

What power does the machine need?

380V / 3-phase industrial power.

How about warranty?

Warranty period: 12 months from the shipping date of machine. Warranty will be not valid if machine subject to misuse or accidental damage or operator’s error. During the valid time, we will supply spare parts. If you have any other questions, pls contact us and we will reply you through product’s photos and videos to make every detail clear. We also provide all lifetime warranty with paid service.

Do you have stock products to sell?

We produce machines in bacth normally. So most models we have some in stock, please check with us before ordering.

Will you supply for OEM orders?

Yes, we can customize the production machine according to your requirements.

Reuqest a Quote

We offer solutions that are tailored to your specific business needs.