Automatic Flute Laminator

Engineered for corrugated packaging manufacturers who need high throughput

⚙️ Up to 13,000 sheets/hour🎯 Accuracy: ±1.0 mm🌍 Global Support

Automatic Flute Laminator

Engineered for corrugated packaging manufacturers who need high throughput

Why Choose Our Automatic Flute Laminator

High Throughput

Up to 13,000 sheets/hour — eliminate production bottlenecks. Our patented Kinetic Energy Recovery System reduces power consumption by up to 30%.

Full-servo Control

Stable, repeatable feed and registration for tight tolerances. Advanced motion control ensures ±1.0mm laminating accuracy even at maximum speed.

Multi-Flute Compatibility

Works on A, B, E, F flutes and multi-ply constructions. Quick changeover minimizes setup time when switching sheet sizes or types.

See Our Automatic Flute Laminator in Action

Watch how our automatic flute laminator delivers flawless results with maximum efficiency

Final Product Samples

Choose Your Model

GE-1450B Automatic flute laminator machine

Model: GE-1450B

Automatic Grade: Automatic

Performance: Adjustable

Patent: Patented Kinetic Energy Recovery System

Max. Speed: 13,000 sheets/hour

Advantages: Low Failure Rate, Safe, Efficiency, Long Life

After-sales Service: Maintenance-Free Automatic Refueling System

Warranty: Not specified.

GM-1450B Automatic flute laminator machine

Model: GM-1450B

Automatic Grade: Automatic

Performance: Adjustable

Patent: Patented Kinetic Energy Recovery System

Max. Speed: 10,000 sheets/hour

Advantages: Low Failure Rate, Safe, Efficiency, Long Life

After-sales Service: Maintenance-Free Automatic Refueling System

Warranty: Not specified.

* Not sure which flute laminator machine is best suited to your needs? Contact our experts.

Product Gallery

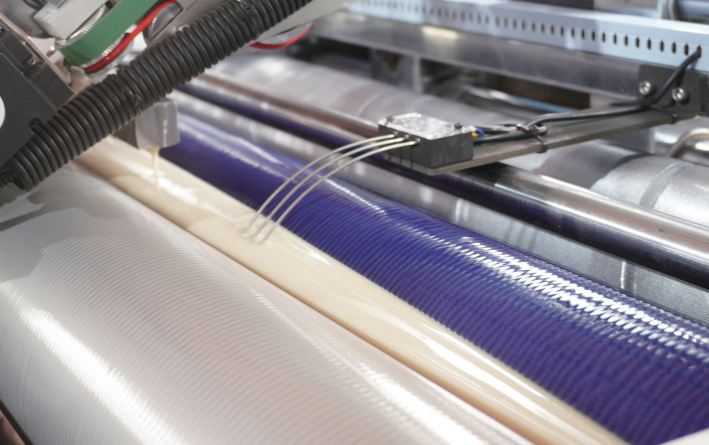

Feeding System for Bottom Paper

- Adopting advanced high speed motion control servo tracking system to ensure laminating accuracy.

Paper Aligning System

- The lifting platform is controlled by 4 sets of double chains to ensure the smooth and safety operation

- 10 limits and protective sensors, real-time detection and adjustment to ensure safety production

- Industry Initiative of servo control lifting platform, single sheet lifting same as offset printing press, without wear, and can be set as from 1~50 sheet/lifting.

Simple Operation Interface

- Full servo automatically adjusts the amount of glue and the height of bottom board, the quality control becomes simpler and easier, and greatly reduces dependence on operator.

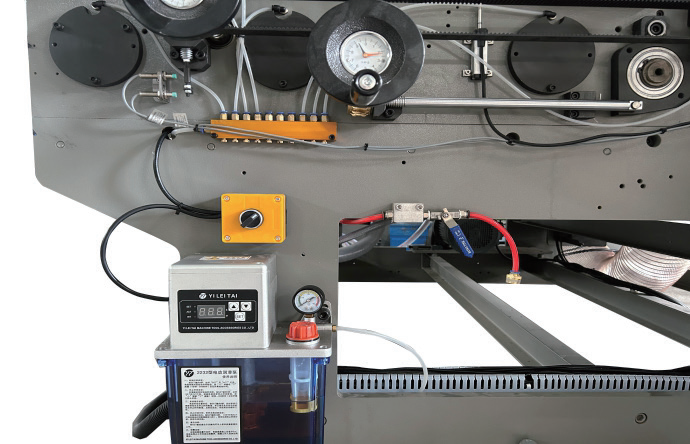

Automatic Lubrication System

- Automatic lubrication system aims for maintenance- free equipment.

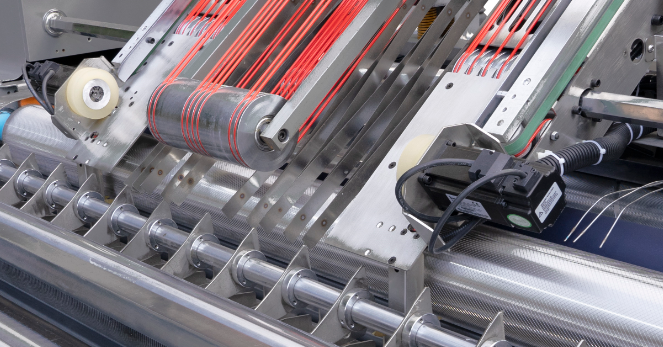

Enlarged Glue Roller

- Enlarged 150mm diameter stainless steel roller, laser engraved anilox, high-speed and stable without glue splashing.

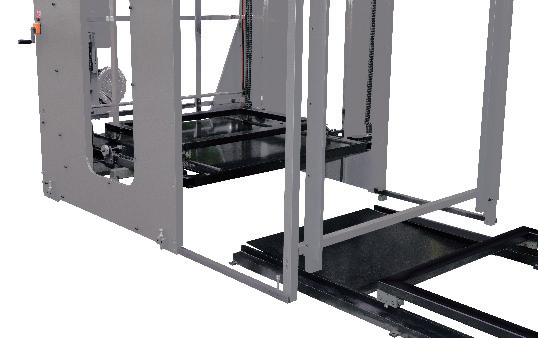

Pre-stacking System

- Whole pallet loading platform, saving labor costs and time.

Technical Specifications

| Specification | GE-1450B | GE-1450BP | GM-1450B |

|---|---|---|---|

| Max. Paper Size (W x L) | 1450 × 1450 mm | 1450 × 1450 mm | 1450 × 1450 mm |

| Min. Paper Size (W x L) | 360 × 360 mm | 360 × 360 mm | 360 × 360 mm |

| Bottom Paper Sheet Thickness | 300 gsm – 10 mm | 300 gsm – 10 mm | 0.3–7 mm |

| Upper Paper Weight | 150 gsm – 700 gsm | 150 gsm – 700 gsm | 150 gsm – 700 gsm |

| Max. Working Speed | 13,000 sheets/hour (153 m/min) Depends on paper quality |

13,000 sheets/hour (153 m/min) Depends on paper quality |

10,000 sheets/hour (150 m/min) |

| Laminating Accuracy (W × L) | ±1.0 mm Standard Sheet Paper |

±1.0 mm Standard Sheet Paper |

±1.5 mm Standard flatboard |

| Applicable Glue | Resin adhesive, starch glue, etc. PH6–8 will be suitable |

Resin adhesive, starch glue, etc. PH6–8 will be suitable |

PVA (white glue), starch adhesives, etc. Recommended pH 6–8 |

| Power Supply | 380 VAC/3P | 380 VAC/3P | 380 VAC/3P |

| Power | 20 kW | 20 kW | 20 kW |

| Kinetic Energy Recovery System | — | — | 4.4 kW regenerative system Recovers over 3 kWh of electrical energy per hour |

| Applicable Substrates | A, B, C, E, F, 3ply, 5ply corrugated board, and cardboard within above mentioned range | A, B, C, E, F, 3ply, 5ply corrugated board, and cardboard within above mentioned range | A, B, E, F flutes, double-flute and other flat corrugated boards; cardboard ≥ 300 gsm for lamination. |

| Machine Weight | 7,000 KG | 7,000 KG | 6,500 KG |

| Overall Dimension (L × W × H) | 15,400 × 2,300 × 2,550 mm | 15,400 × 2,300 × 2,550 mm | 11,500 × 2,300 × 2,550 mm |

* Need a tailored spec? Contact our sales engineers for configuration and site requirements.

Why Customers Trust Fengchi

Certified Quality

ISO 9001:2015 certified manufacturing. CE certified for European markets. All critical components from globally renowned suppliers.

Comprehensive Warranty

12-month comprehensive warranty on all parts and labor. Lifetime technical support and paid service plans available.

24/7 Support

Round-the-clock technical support with response within 24 hours. Multilingual support team.

Global Installations

3,200+ machines installed across 60 countries with proven reliability in diverse manufacturing environments.

What Our Customers Say

Hear from industry leaders who have transformed their production with our automatic flute laminators

The quick changeover feature lets us handle short runs profitably. We’ve diversified our client base without adding staff. This machine transformed our business model.

– John Smith, Production Manager

The technical support is exceptional. When we had a minor issue, their team resolved within 24 hours.

– Maria Johnson, Operations Director

The precision and consistency of the flute laminator have significantly improved our product quality.

– Robert Williams, CEO

Trusted by Industry Leaders Worldwide

Our Service for Your Success

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines.

Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

Frequently Asked Questions

Which flutes does it support?

A, B, E, F and multi-ply constructions.

What's the lead time?

Typically 10–30 working days depending on model and configuration.

How about installation and training?

Normally, one operator can finish intallation in 2 hours with installation manual and video. If purchaser’s engineer travels at own cost to China, free training session. If engineer sent to purchaser’s factory, all travel cost paid by purchaser.

How about warranty?

Warranty period: 12 months from the shipping date of machine. Warranty will be not valid if machine subject to misuse or accidental damage or operator’s error. During the valid time, we will supply spare parts. If you have any other questions, pls contact us and we will reply you through product’s photos and videos to make every detail clear. We also provide all lifetime warranty with paid service.

Will you supply for OEM orders?

Yes, we can customize the production machine according to your requirements.

Request a Quote

Need help to find the right corrugated laminating solution with our experts?