Folder Gluer Stitcher

Automatic folder gluer stitcher designed for corrugated box production.

1600 stitches/min. Switch jobs in just 3-5 minutes

Folder Gluer Stitcher

Automatic folder gluer stitcher designed for corrugated box production.

Automatic Folder Gluer Stitcher

Our cutting-edge Automatic Folder Gluer Stitcher Machine delivers unmatched efficiency and durability, streamlining your production line for corrugated and folding carton packaging.

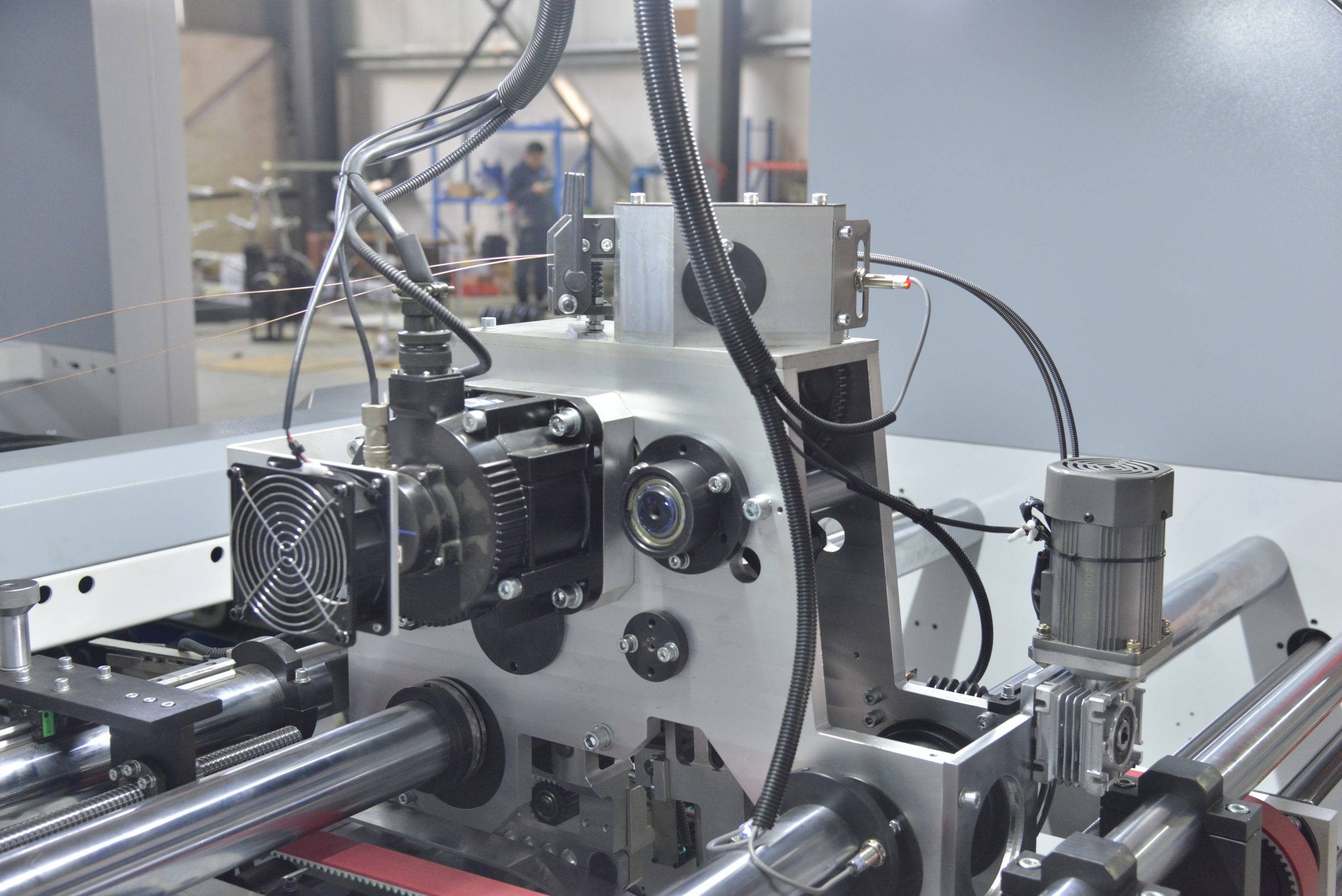

HD Series Folder Gluer Stitcher

Designed for high-speed, precision performance, the HD Series combines advanced engineering with practical functionality to optimize your packaging production.

With features like the patented active line pressing device and split air suction units, we solve common industry challenges while reducing maintenance costs and downtime.

See It in Action

Ideal For These Applications

Food & Beverage Packaging

Hygienic, high-speed folding for food-safe cartons

Fruit & Produce Cartons

Ventilated designs for fresh produce packaging

Furniture & Home Décor Boxes

Sturdy construction for heavy items

Medical & Pharmaceutical Packaging

Precision folding for regulatory compliance

Daily Chemical Products

Reliable performance for high-volume production

Hardware & Industrial Components

Durable packaging for industrial parts

HD Series Models

Choose from our range of high-performance automatic folder gluer stitching machines designed for different production requirements.

HD-2800 Automatic folder gluer and stitching machine

- Max Sheet Size: 2800mm × 1200mm

- Max Stitching Speed: 1600 stitches/min

- Power: ≤ 23 KW

- Machine Net Weight: 9.7T

- Ideal for standard carton production

HD-2800 Ultra Automatic folder gluer and stitching machine

- Max Sheet Size: 2800mm × 1200mm

- Max Stitching Speed: 1600 stitches/min

- Automatic feeder pressure adjustment

- Folding part full servo control

- Customized small side folding

HD-3600 Automatic folder gluer and stitching machine

- Max Sheet Size: 3600mm × 1600mm

- Max Stitching Speed: 1600 stitches/min

- Power: ≤ 31 KW

- Machine Net Weight: 12T

- For large-format, heavy-duty packaging

Technical Specifications

| Model | HD-2800 | HD-2800 Ultra | HD-3600 |

|---|---|---|---|

| Sheet Size Specifications | |||

| Max.Sheet Size (W × L) | 2800mm × 1200mm | 2800mm × 1200mm | 3600mm × 1600mm |

| Min.Sheet Size (W × L) | 830mm × 300mm | 760mm × 300mm | 1160mm × 400mm |

| Performance Specifications | |||

| Max stitching speed | 1600 stitches/min | ||

| Sticking gap | 40-500mm | ||

| Stitching quantity | 1-99 | ||

| Stitch angle | 45° | ||

| Physical Specifications | |||

| Machine net weight | 9.7T | 11T | 12T |

| Machine size (L × W × H) | L17000mm × W4100mm × H2200mm | L17000mm × W4100mm × H2300mm | L19000mm × W4400mm × H2800mm |

| Power & Air Requirements | |||

| Air source | 0.6-0.8Mpa | ||

| Power source | 380VAC/3P, 50Hz | ||

| Power | ≤ 23 KW | ≤ 28 KW | ≤ 31 KW |

| Material Compatibility | |||

| Applicable paper | A, B, C, AB flute, 3ply, 5ply, 7ply corrugated paper | ||

| Automation Features | |||

| Automatic feeder pressure adjustment | No | Yes | Yes |

| Automatic stitching head pressure adjustment | No | Yes | Yes |

| Customized small side folding | No | Yes | Yes |

| Folding part full servo control | No | Yes | Yes |

* This is the current configuration. It may be updated as technology evolves.

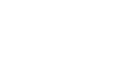

Why Partner with Fengchi?

High Quality

Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Vast Experience

More than 15 years of experience within automation gives us an enormous know-how and expertise in laminating solutions.

30 + Patents

We continuously push the boundaries of speed and performance, securing 30 patents through independent research and development.

Global Support

We proudly export corrugated laminating solutions worldwide, ensuring international clients benefit from our innovative technology.

Our Service for Your Success

Our service team ensures maximum production reliability and efficiency.

From mechanical and electrical assembly to performance calibration and operator training, our specialists ensure every piece of technology works flawlessly from day one. And with aftermarket support built on responsiveness and expertise, your uptime becomes our priority.

Whether you need parts, maintenance or digital remote support, we are here for you: sales@laminatorfc.com

Frequently Asked Questions

What types of corrugated paper does the HD Series handle?

The HD Series Folder Gluer Stitcher handles A/B/C/AB flute, 3-ply, 5-ply, and 7-ply corrugated paper with ease.

How easy is changeover?

Touchscreen presets reduce changeover time significantly; exact time depends on operator training and job complexity.

What warranty/support?

Standard 12-month warranty; global spare parts and service available.

Delivery & lead time?

Typical lead time: 10–30 days (confirm per order). The specific delivery time depends on the product and the order quantity.

Will you supply for OEM orders?

Yes, we can customize the production machine according to your requirements.

Interested in an automatic folder gluer stitcher?

Contact Form

TEL