Full Servo Flip Flop Stacker

Full Servo Flip Flop Stacker — High‑Speed, Fully Automatic Stacking for Flute Laminators

Flip, align and stack laminated sheets automatically — reduces labor, prevents curled sheets, and keeps your line running.

Full Servo Flip Flop Stacker

Flip, align and stack laminated sheets automatically — reduces labor, prevents curled sheets, and keeps your line running.

Quick Benefits

A non-stop machine with a maximum sheet size of 2100 x 1650 mm and a minimum of 500 x 380 mm. It has a maximum working speed of 15,000 sheets/hour with a maximum stack height of 1700 mm.

- Matches high‑speed flute laminators — keep production flowing

- Reduces manual handling and rework

- Touchscreen presets for fast changeovers

- Up to 15,000 sheets/hr, full‑servo precision, quick changeovers

Model examples: FZ‑1450 • FZ‑1700 • FZ‑2200

How It Works — 4 Quick Steps

- Sheets delivered from the flute laminator into the receiving belt.

- Servo-driven turner flips sheets and compensates for registration.

- Stacer collects and aligns into preset pile counts.

- Optional non‑stop pallet change keeps throughput continuous.

Full‑Servo Drive

Smooth, repeatable flipping and precise pile alignment — fewer jams and consistent pallet-ready stacks.

High‑Speed Capability

Matches flute laminator outputs (ideal for production lines up to 15k sheets/hr) — no bottlenecks.

Adjustable Presets & Memory

Fast changeovers for varied jobs; reduces setup time and operator training.

Technical Specifications

| Parameter / Model | FZ-1450 | FZ-1700 | FZ-2200 |

|---|---|---|---|

| Max Sheet Size | 1450 × 1450 mm | 1700 × 1650 mm | 2100 × 1650 mm |

| Min Sheet Size | 500 × 380 mm | 550 × 380 mm | 600 × 380 mm |

| Max Working Speed | 15,000 sheets/hour | 15,000 sheets/hour | 15,000 sheets/hour |

| Weight | 3,800 kg | 4,000 kg | 5,600 kg |

| Dimension (L × W × H) | 6955 × 2432 × 2892 mm | 7555 × 2682 × 2892 mm | 9120 × 2910 × 2892 mm |

| Power | 12 kW | 12 kW | 14 kW |

| Voltage | 380 VAC/3P | 380 VAC/3P | 380 VAC/3P |

| Gas Source | 0.8 Mpa>5.5 kW | 0.8 Mpa>5.5 kW | 0.8 Mpa>5.5 kW |

*Specifications may vary by model. Contact us for custom configurations.

Product Gallery

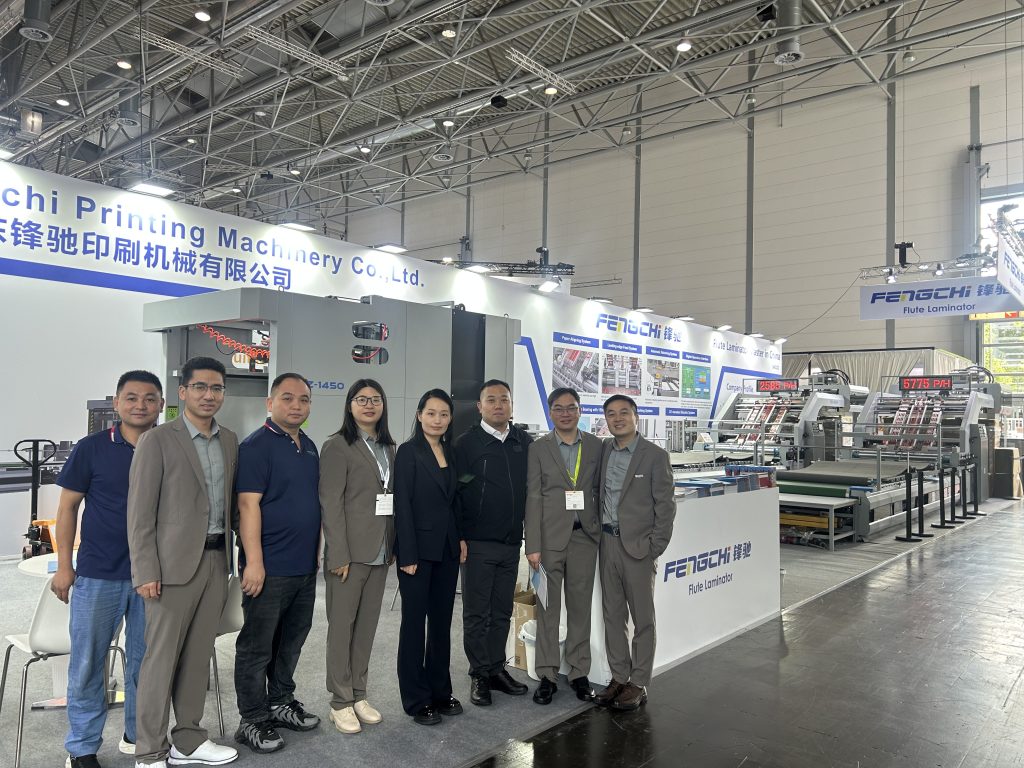

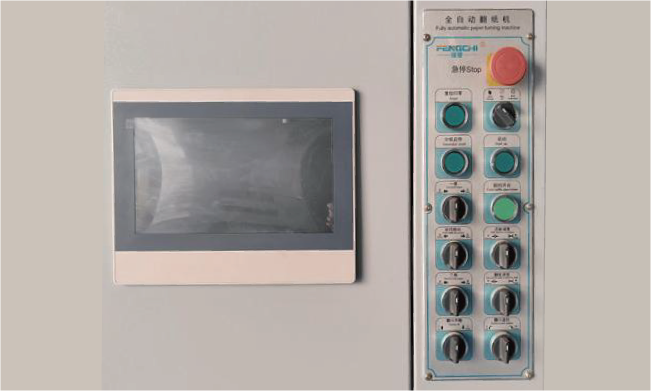

Electrical Control System

- The system adopts internationally advanced motion control technology and digital control, ensuring smoother, faster, and more stable machine operation with easier usability.

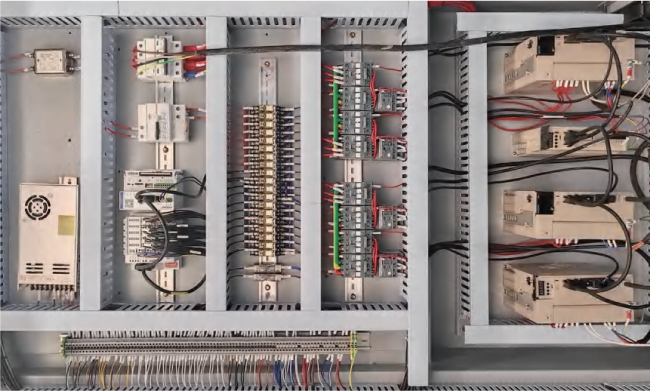

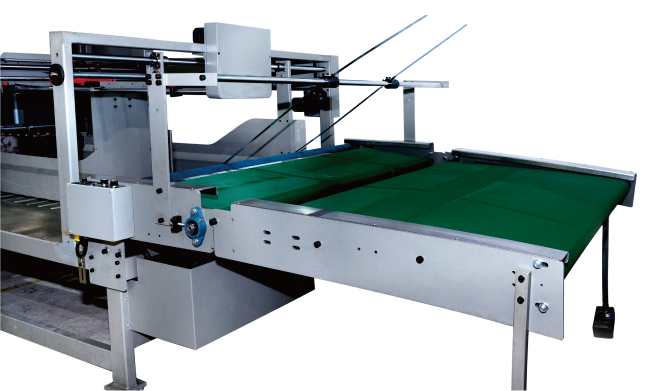

Pile Turning Mechanism

- Adopting high-speed silent track which is smooth, silent, wear-free, and with long-term service life. The flipping servo and lifting servo electronic cam are locked, the flipping lifting speed can be adjusted disposable.

Lubrication

- Adopting simple man-machine interface which only needs to input the paper size, one key to adjust the machine, no need to use any tools, one key to start. The equipment adopts operation control technology.

Paper Division

- The three-section independent frequency conversion speed regulation mechanism can adjust the speed of each section of the paper according to the thickness of the paper output from the main machine press.

Why Choose Fengchi

High Quality

Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Vast Experience

More than 15 years of experience within automation gives us an enormous know-how and expertise in laminating solutions.

30 + Patents

We continuously push the boundaries of speed and performance, securing 30 patents through independent research and development.

Global Support

We proudly export corrugated laminating solutions worldwide, ensuring international clients benefit from our innovative technology.

Trusted by Industry Leaders Worldwide

What Customers Say

This machine has been a game-changer for our production line. The fully automated stacking process is incredibly smooth and precise. We’ve been able to reallocate two operators to more skilled tasks, which has boosted our overall team morale and reduced our labor costs significantly.

– David L., Owner

The fully automated stacking process is incredibly smooth and precise. The speed and consistency are exactly as promised, and it has completely eliminated the bottlenecks we used to have at the end of our litho laminator.

– Mark R., Production Manager

Smooth integration with our flute laminator line and near-zero jams. We increased output by 48% after installing the flip-flop stacker.

– Sarah Lee, Operations Director

Our Technical Service

After Sales service begins with the arrival of the machinery at the customer’s factory.

To maximize investment whether a single machine or an entire line, the equipment needs to enter the existing production quickly and deliver its contribution. Fengchi offers a dedicated team of technicians that assemble, calibrate and commission the machinery.

Our engineers teach customer operators the machines function, calibration, available options, best practice and scheduled housekeeping.

Fengchi is always available to its customers if they have a problem, concern or malfunctionwith their machinery.

Frequently Asked Questions

What is the max speed of the flip flop stacker?

Up to 15,000 sheets/hour depending on model and substrate.

What materials can the stacker handle?

A, B, C, E, and F flutes, as well as multi-ply corrugated cardboard.

How easy is changeover?

Touchscreen presets reduce changeover time significantly; exact time depends on operator training and job complexity.

What warranty/support?

Standard 12-month warranty; global spare parts and service available.

Can it integrate with my litho laminator?

Yes — drop-in integration with major laminator lines via sync signal.

Delivery & lead time?

Typical lead time: 10–30 days (confirm per order). The specific delivery time depends on the product and the order quantity.

Will you supply for OEM orders?

Yes, we can customize the production machine according to your requirements.

Tell Us About Your Project

By filling in your information, we will provide you with a personalized quote.