FengChi Product

FULL SERVO HIGH SPEED FLUTE LAMINATOR

Fengchi - No.1 in the global market share of high-speed flute laminators

Fengchi is the China’s leading provider of automatic flute laminators and solutions for production in the corrugated and folding carton.

Our full servo high speed flute laminators are equipped with full servo flip flop stackers for maximum capacity. Operating speed – 16,000 sheets per hour at steady state and up to 22,000 sheets per hour at peak operation.

We are dedicated to providing you with the best post-press equipment solutions to help you achieve your goals. Our team of experts is always available to help you find the right machinery and parts for your needs. We pride ourselves on our exceptional customer service and support, ensuring that you get the most out of your machinery investment.

We prioritize peak performance and efficiency through comprehensive training, minimizing downtime and maximizing productivity.

With over 2,000 successfully completed projects in over 50 countries, Fengchi supports our customers with innovative solutions and are a reliable and trusted partner. Contact our experts to discuss your needs in detail.

High Speed Flute Laminator Machine Video Demo

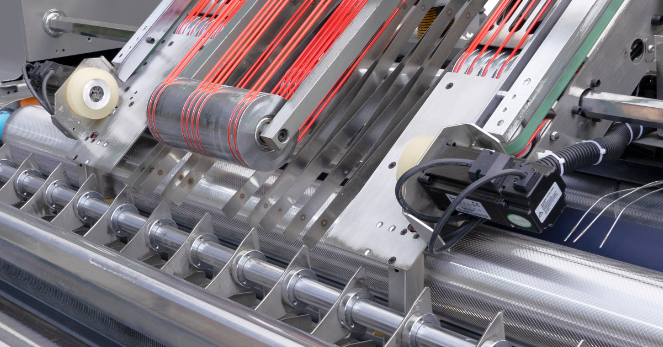

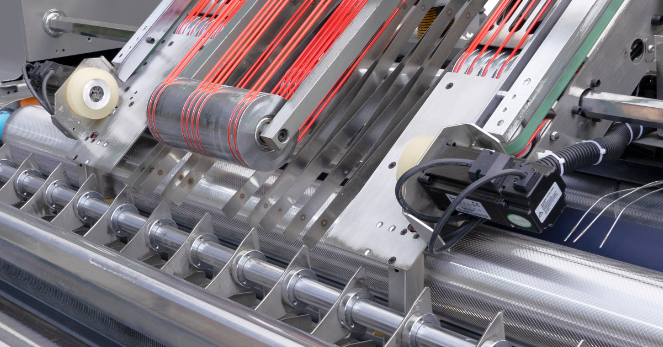

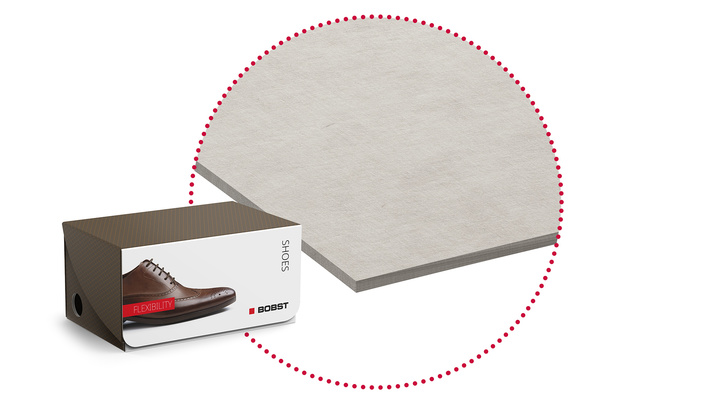

Explore our state-of-the-art flute laminator machines. Engineered for superior efficiency, precision, and durability, our innovative flute laminator machine is specially designed for laminating colored surface paper onto corrugated sheet to produce aesthetically pleasing, high quality corrugated board.

GW SERIES FLUTE LAMINATOR FEATURES

- Max speed 22,000 sheets/hour, stable high speed 16,000 sheets/hour for 24hours/day running.

- Easy to switch according to different production batches: Make ready in 2-5 minutes lmprove production efficiency.

- Power consumption about 8KW/h, saving about 20% of power.

- Digital intelligent design, automatic glue adjustment, pressure adjustment automatic lubrication for bearing, the technical regurements tor equipment operator sreduced by 80%.

- Enlarged 150mm diameter stainless steel roller, laser engraved anilox, glue apply evenly, fine glue line, no glue-splash, glue used about 18g/m², saving 30% of the glue.

- Full servo bus control systems, high-speed and stable laminating with the accuracy +1.0mm.

- Reserved 35% margin of servo motor and drive loading, prolong life cycle over 15 years, ensure the lamination accuracy unchanged.

MACHINE HIGHLIGHTS

SPECIFICATION

| Models | GW-1450L | GW-1450LP | GW-1450BP | GW-1700L | GW-1700LP | GW-1700BP | GW-2200L | GW-2200LP | GW-2200BP |

|---|---|---|---|---|---|---|---|---|---|

| Max. paper size | W 1450mm * L 1450mm | W 1450mm * L 1450mm | W 1450mm * L 1450mm | W 1700mm * L 1650mm | W 1700mm * L 1650mm | W 1700mm * L 1650mm | W 2200mm * L 2100mm | W 2200mm * L 2100mm | W 2200mm * L 2100mm |

| Min. paper size | W 360mm * L 360mm | W 360mm * L 360mm | W 360mm * L 360mm | W 360mm * L 360mm | W 360mm * L 360mm | W 360mm * L 360mm | W 450mm * L 380mm | W 450mm * L 380mm | W 450mm * L 380mm |

| Bottom Paper Sheet Thickness | F flute-10mm | F flute-10mm | 300gsm – 10mm | F flute-10mm | F flute-10mm | 300gsm – 10mm | F flute-10mm | F flute-10mm | 300gsm – 10mm |

| Upper Paper Sheet Thickness | 150 g-700 g | 150 g-700 g | 120g-700g | 150 g-700 g | 150 g-700 g | 120g-700g | 150 g-700 g | 150 g-700 g | 120g-700g |

| Max. Working Speed | 16000 Sheets/Hour (165 M/Min) | ||||||||

| Laminating Accuracy | ±1.0mm (Standard Sheet Paper) | ||||||||

| Applicable Glue | Resin adhesive, starch glue and etc (PH6~8) | ||||||||

| Machine Weight | 8000KG | 8000KG | 8000KG | 8500KG | 8500KG | 8500KG | 9000KG | 9000KG | 9000KG |

| Dimension (LxWxH) | L 15700mm * W2400mm *H 2550mm | L 15700mm * W2400mm *H 2550mm | L 15700mm * W2400mm *H 2550mm | L 16300mm * W 2650mm *H 2550mm | L 16300mm * W 2650mm *H 2550mm | L 16300mm * W 2650mm *H 2550mm | L 18500mm * W 3050mm* H 2880mm | L 18500mm * W 3050mm* H 2880mm | L 18500mm * W 3050mm* H 2880mm |

| Power Supply | 380VAC/3P | 380VAC/3P | 380VAC/3P | 380VAC/3P | 380VAC/3P | 380VAC/3P | 380VAC/3P | 380VAC/3P | 380VAC/3P |

| Power | 26KW | 26KW | 26KW | 30KW | 30KW | 30KW | 32KW | 32KW | 32KW |

| Applicable Corrugated Board | A, B, C, E, F, 3ply, 5ply, 7ply corrugated board, and cardboard within above mentioned thickness range | A, B, C, E, F, 3ply, 5ply, 7ply corrugated board, and cardboard within above mentioned thickness range | Cardboard above 300gsm, and A, B, C, E, F, 3ply, 5ply corrugated board | A, B, C, E, F, 3ply, 5ply, 7ply corrugated board, and cardboard within above mentioned thickness range | A, B, C, E, F, 3ply, 5ply, 7ply corrugated board, and cardboard within above mentioned thickness range | Cardboard above 300gsm, and A, B, C, E, F, 3ply, 5ply corrugated board | A, B, C, E, F, 3ply, 5ply, 7ply corrugated board, and cardboard within above mentioned thickness range | A, B, C, E, F, 3ply, 5ply, 7ply corrugated board, and cardboard within above mentioned thickness range | Cardboard above 300gsm, and A, B, C, E, F, 3ply, 5ply corrugated board |

Suitable for the following industries

End-use categories

Main processed materials

FengChi Service

Expert Service & Support

Are you interested in our product?

Contact us

TEL