FengChi Product

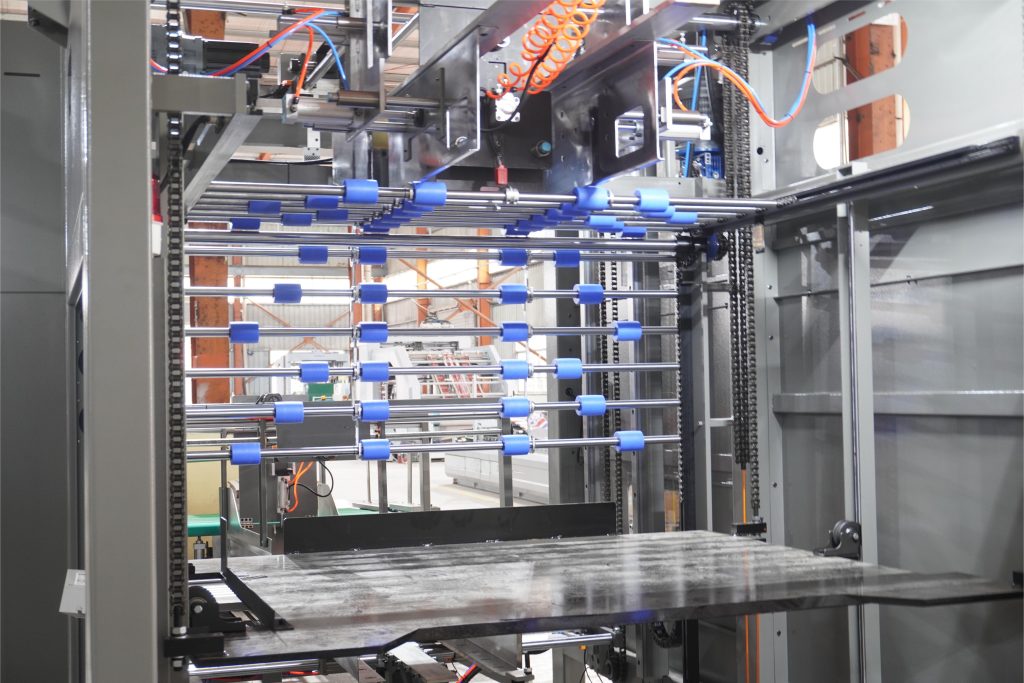

HIGH SPEED FLUTE LAMINATOR WITH FLIP FLOP STACKER

Fengchi - No.1 in the global market share of high-speed flute laminators

Fengchi is the China’s leading provider of automatic flute laminators and solutions for production in the corrugated and folding carton.

Our high-speed flute laminator and flip flop stacker have adopting of 12 servo motors plus bus control systems. The industry imitative of high stable and eficient control system has achieved the integration of laminating, turning, and paper colection which areatly improved the post-press paper laminating capacity, and promoted the inteligent development, transformation, upgrading of the carton and printing industries.

We pride ourselves on our exceptional customer service and support, ensuring that you get the most out of your machinery investment.

With over 2,600 successfully completed projects in over 50 countries, Fengchi supports our customers with innovative solutions and are a reliable and trusted partner. Contact us today for a consultation!

High Speed Flute Laminator With Flip Flop Stacker Video Demo

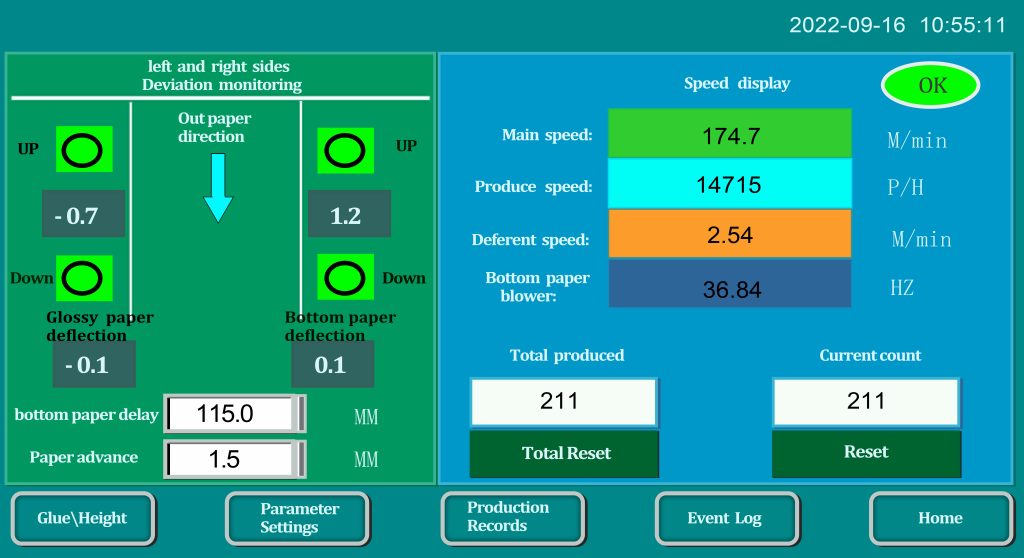

Our automatic flute laminator is specially designed for laminating colored surface paper onto corrugated sheet to produce aesthetically pleasing, high quality corrugated board. Full servo high-speed automatic flute laminator machine is equipped with flip stacker for maximum capacity. They has max speed of 22,000 sheets per hour, and a stable high speed of 16,000 sheets per hour for 24hours/day running. Do you want more information about this product? Please contact us today.

GW SERIES HIGH SPEED FLUTE LAMINATOR FEATURES

- Max speed 22,000 sheets/hour, stable high speed 16,000 sheets/hour for 24hours/day running.

- Easy to switch according to different production batches: Make ready in 2-5 minutes lmprove production efficiency.

- Power consumption about 8KW/h, saving about 20% of power.

- Digital intelligent design, automatic glue adjustment, pressure adjustment automatic lubrication for bearing, the technical regurements tor equipment operator sreduced by 80%.

- Enlarged 150mm diameter stainless steel roller, laser engraved anilox, glue apply evenly, fine glue line, no glue-splash, glue used about 18g/m², saving 30% of the glue.

- Full servo bus control systems, high-speed and stable laminating with the accuracy +1.0mm.

- Reserved 35% margin of servo motor and drive loading, prolong life cycle over 15 years, ensure the lamination accuracy unchanged.

FZ Stacker Features

- Full servo motion control system, high speed, smooth operation and trouble-free

- High-speed silent track, quiet operation, long-term life cycle

- Minimalist operating system, safe and reliable without training, easy to operate

- Max speed 16,000 sheets/hour

- Safety protection with alarm and machine stop

Full-servo high speed flute laminating machine

Guangdong Fengchi Printing Machinery Co., Ltd., as a leader in the industry of high-speed flute laminating machine, has been committed to the research and development of high-speed flute laminating machines over 15 years. With the design concept of intelligence, digitization, automation, high energy efficiency and Eco friendly, our high-speed flute laminating machine and flip flop stacker have adopting of 12 servo motors plus bus control systems. The industry imitative of high stable and efficient control system has achieved the integration of laminating, turning, and paper collection which greatly improved the post-press paper laminating capacity, and promoted the intelligent development, transformation, upgrading of the carton and printing industries.

SPECIFICATION

| Models | GW-1450L/B GW-1450LP/BP | GW-1700L/B GW-1700LP/BP | GW-2200L/B GW-2200LP/BP |

| Max. sheet size (W × L) | 1450mm * 1450mm | 1700mm * 1650mm | 2200mm *2100mm |

| Min. sheet size (W × L) | 420mm * 380mm | 420mm * 380mm | 450mm * 480mm |

| Bottom Paper Sheet Thickness | F flute-10mm | F flute-10mm | F flute-10mm |

| Upper Paper Sheet Thickness | 150 g-700 g | 150 g-700 g | 150 g-700 g |

| Max. Working Speed | 22,000 Sheets/Hour (175M/Min) | 22,000 Sheets/Hour (175M/Min) | 22,000 Sheets/Hour (175M/Min) |

| Laminating Accuracy | ±1.0mm (Standard Sheet Paper) | ||

| Applicable Glue | Resin adhesive, starch glue and etc (PH6~8 will be suitable for laminating glue) | ||

| Machine Weight | 8000KG | 8500KG | 9000KG |

| Dimension (LxWxH) | L 15700mm * W2400mm *H 2550mm | L 16300mm * W 2650mm *H 2550mm | L 18500mm * W 3050mm* H 2880mm |

| Power Supply | 380VAC/3P | 380VAC/3P | 380VAC/3P |

| Power | 26KW | 30KW | 32KW |

| Applicable Corrugated Board | A, B, E, F, three-layer, 5-layer, and other deformed, warped corrugated papers | ||

Product Detail

Pre–stacking loading:

for sheet uneven stacking or with static electricity, manual pre–stacking on pre–loading platform, and keep the job–change over within 3mins.Whole pallet loading:

adopt the whole pallet loading design to save the manpower and time. After the pallet is loaded against the gear gauge, aligning the zero position to make left and right adjustment.Separate manual stacking:

when the platform descend, manual stack the paper on the pallet.

The lifting platform is controlled by 4 sets of double chains to ensure the smooth and safety operation.

10 limits and protective sensors, real-time detection and adjustment to ensure safety production.

Industry Initiative of servo control lifting platform, single sheet lifting same as offset printing press, without wear, and can be set as from 1–50 sheet/lifting.

Industry Initiative of high speed shaft–less feeder, smooth feeding, maintenance–free, max speed up to 22,000sheet/hour.

The correction system of paper feeding ensure the high speed feeding smoothly without any skew.

The sheet delivery stopper make sure the single sheet feeding, optional to upgrade by adding double sheet detection system.

Becker vacuum pump with large suction, strong blowing, good stability and durable.

Standard space is 3m, option shorten to 2.3m.

Large working space, available for more pallets place and convenient operation.

Industry Initiative of leading edge bottom feeder, suitable for a variety of warped deformation, rough and heavy bottom board feeding.

Unidirectional rotation feeding roller, without wear, life cycle up to 10 years.

Standard equipped with right cylinder to pile up the paper in neat, available to adjust in a whole or on the right side, greatly saving manpower.

Patented non–stop suction with 5.5KW power, air flow adjustable at will.

Extra heavy wear–resistant belt, suitable for cardboard/flute laminating, without scratch in conveying.

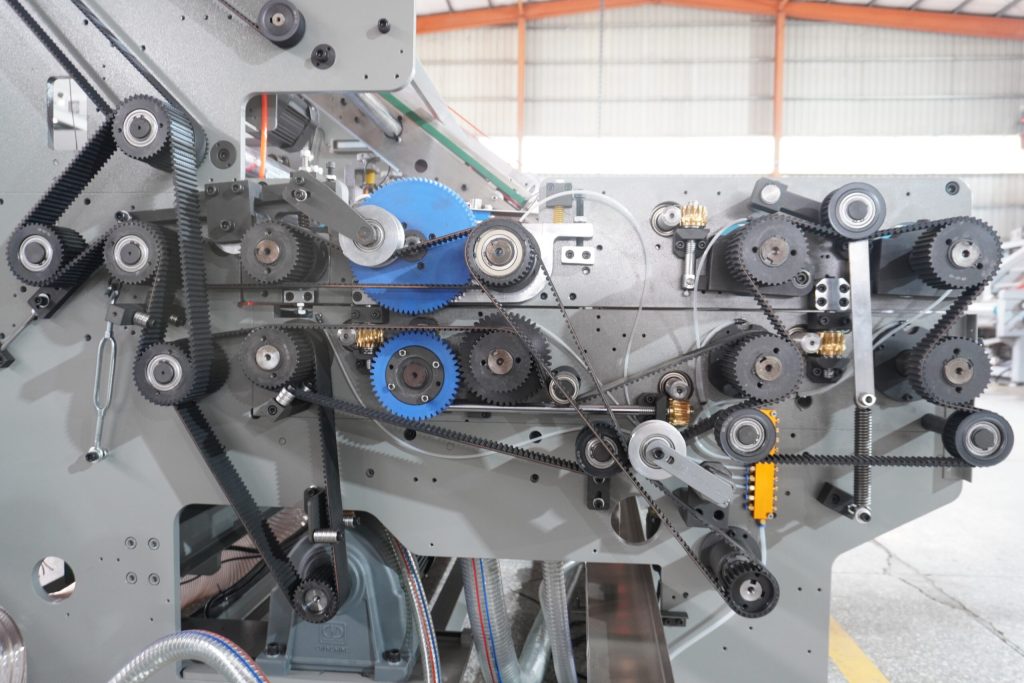

Using 60mm extra widening timing belts instead of traditional wheel chain, make sure the synchronous wheel and timing belt perfect transmission, truly achieve zero wear, and ensure the lamination in high accuracy at any time.

Industry initiative of double bearing design, effectively extend the life span of the bearings.

Industry initiative of auto bearing oiling injection system, maintenance free to saving manpower.

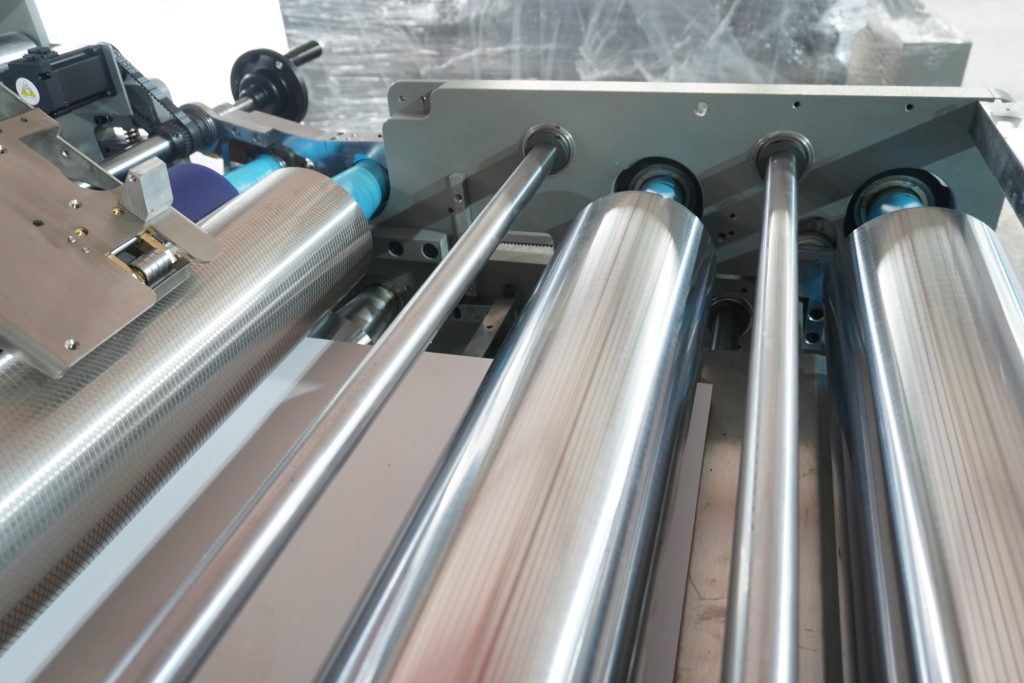

Industry initiative of enlarged diameter 150mm stainless steel roller, uniform pressure, high-speed and stable without glue splashing.

Laser engraving glue roller, special rhombic pattern, even and fine glue line, effective saving about 30% of glue.

Unique long wheelbase roller to avoid damage caused by glue/water spilling into the bearing during laminating and cleaning.

Automatic glue refueling device, coordinated with automatic monitor and recycling glue system to ensure glue quality and avoid the waste.

The pressing roller ensures the smooth feeding of the bottom sheet, and double pressing rollers make the lamination in perfect.

Adopting the servo control system, calculating the position of the front gauge separately per each sheet, and the servo automatically tracks and compensates to ensure the stability and high accuracy of the front gauge.

Belt length can be adjusted automatically to fit with different size of products.

Thickened sponge carpet to avoid crack at top edge of board.

Standard with 6m length of enhanced conveying part (optional shorten to 5m).

Full–Servo Flip Flop stacker

FENGCHI vertical full servo flip flop stacker is designed to interconnect with FENGCHI full servo high speed cardboard/flute laminating machine as the automation of laminating production line. The laminated and pressed sheet is through the conveyor to be stacked up into a pile as per setting quantity. It combines the functions of flipping paper intermittently, stacking paper on front side up or back side up, tidy stacking to pallet and finally come out automatically. FENGCHI full–servo flip flop have a greatly to optimize the working state, to save manpower & labor intense, and to increase the production capacity.

SPECIFICATION

| Model | FZ–1450 | FZ–1700 |

|---|---|---|

| Max. Sheet Size (W×L) | 1450mm × 1450mm | 1700mm × 1650mm |

| Min. Sheet Size (W×L) | 500mm × 380mm | 500mm × 380mm |

| Max. Working Speed | 16,000 sheet/hour | 16,000 sheet/hour |

| Machine Weight | 3800kg | 4000kg |

| Dimension (L×W×H) | 6955mm × 2432mm × 2892mm | 7555mm × 2682mm × 2892mm |

| Power | 380VAC / 3P | |

| Power | 12kw | 12kw |

| Gas Source | 0.8MPa >5.5KW | |

Product Detail

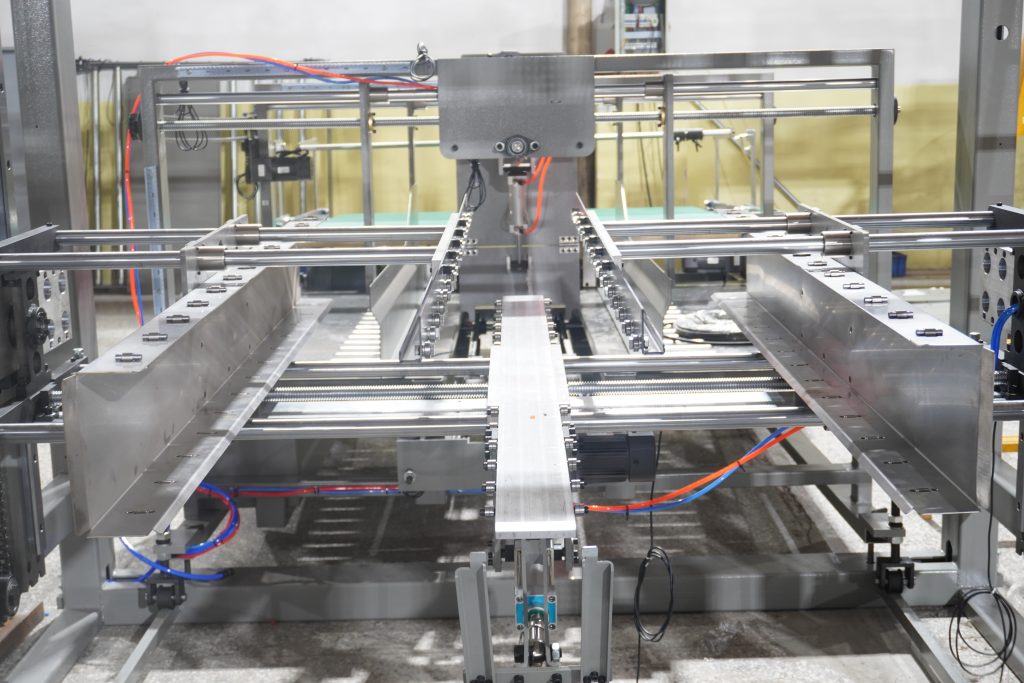

- The lamination machine connects flip flop stacker with one button operation. Digital input the sheet size on lamination machine, and interconnect with flip flop stacker to adjust the flap and location block automatically. In action, the flip flop is with independent touch screen to control and fine turn.

- Multi-phase sheet separating design, make sure the sheet conveying smoothly and tidy stacking.

Using 5 sets of servo control, precise positioning, unimpeded sheet push, multi-speed control of the whole process of paper collection, perfect separating different length of the paper. The collecting speed increases over 30%.

The stacking height of the paper can be adjusted at will.

Servo controlled slap in front and two sides to make the paper filed neatly.

Non-stop collection with pre-stacking device, stacking height up to 1700mm.

The servo controlled lifting platform is supported by 4 sets of double chains to ensure the smooth and safe operation.

Auto pallet makeup function: when the full stacked pallet comes out automatically, the makeup pallet will be in place and lifted automatically to keep the collection non-stop.

Auto logistics system: automatically supplying the empty pallet and full stacked pallets come out keeps the receiving smoothly, saving the manpower.

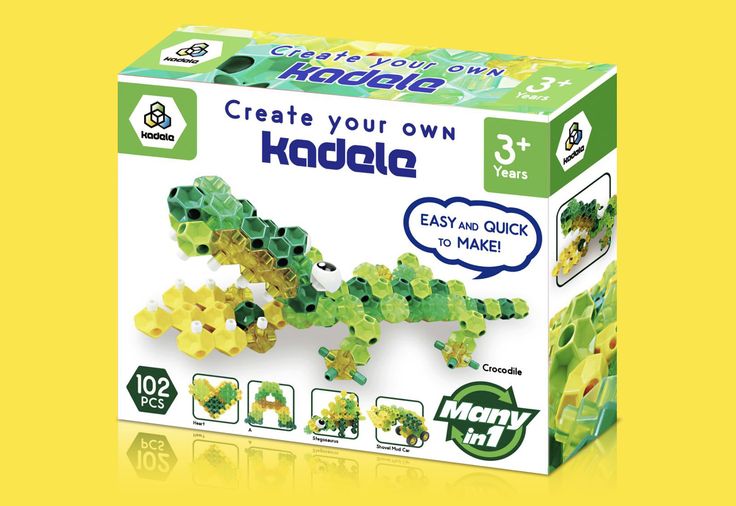

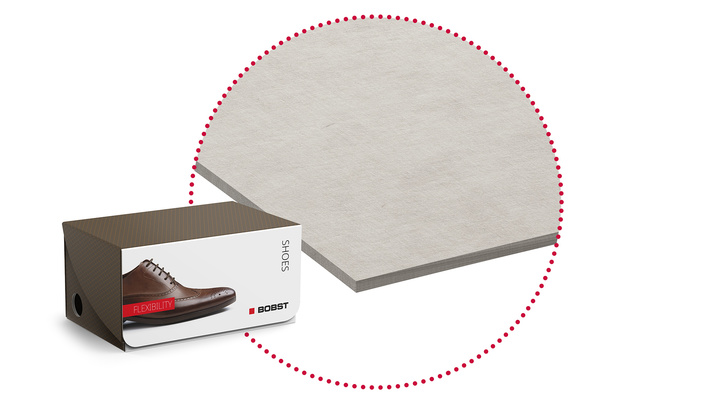

Suitable for the following industries

End-use categories

Main processed materials

FengChi Service

Expert Service & Support

Are you interested in our product?

Contact us

TEL