GW-1100L Flute Laminator

GW-1100L — Built for high-volume corrugated lamination

Max speed 15,000 sheets/hour. Accuracy: ±1.5 mm

GW-1100L Flute Laminator

GW-1100L — Built for high-volume corrugated lamination

Key Features & Benefits

The GW-1100L automatic flute laminators are specifically engineered for reliable, energy-efficient corrugated board lamination processes.

High Throughput

Maximum laminating speed up to 15,000 sheets/hour with servo positioning system for both cardboard and corrugated paper.

Precision Alignment System

Advanced sensors and servo motors ensure perfect alignment between liner and flute for consistent quality.

Multi-Flute Compatibility

Works on A, B, E, F flutes and multi-ply constructions. Quick changeover minimizes setup time when switching sheet sizes or types.

User-Friendly Interface

Maximum laminating speed up to 15,000 sheets/hour with servo positioning system for both cardboard and corrugated paper.

Advanced Safety Features

Comprehensive safety systems including emergency stops, guards, and automated shutdown protocols.

Easy Maintenance

Modular design with quick-access panels simplifies maintenance and reduces downtime.

End-use Packaging Samples

Case Studies

Spanish Client Case Study

Mexican Client Case Study

Australian Client Case Study

Technical Specifications

| Model | GW-1100L |

|---|---|

| Max. paper size (W x L) | 1100 × 1200 mm |

| Min. paper size (W x L) | 360 × 360 mm |

| Bottom Paper Sheet Thickness | 0.3 – 7mm |

| Upper Paper Sheet Thickness (W*L) | 150 gsm-700 gsm |

| Max. Working Speed | 15,000 Sheets/Hour (153M/min) (Depends on paper quality) |

| Laminating Accuracy (W*L) | ±1.5 mm (Standard Sheet Paper) |

| Applicable Glue | White glue, starch glue, etc. (Glue with PH6–8 suitable for lamination) |

| Power Supply | 380 VAC/3P |

| Power | 20 kW |

| Applicable paper | Flat corrugated boards (flute types A, B, E, F, double-wall, etc.) and cardboard weighing ≥ 300 g/m² for lamination |

| Kinetic Energy Recovery System | 4.4 kW energy recovery system, recovers ≥ 3 kWh per hour |

| Machine weight | 6000 KG |

| Overall dimension (L*W*H) | 13600 × 2000 × 2550 mm |

* Need a tailored spec? Contact our sales engineers for configuration and site requirements.

Product Gallery

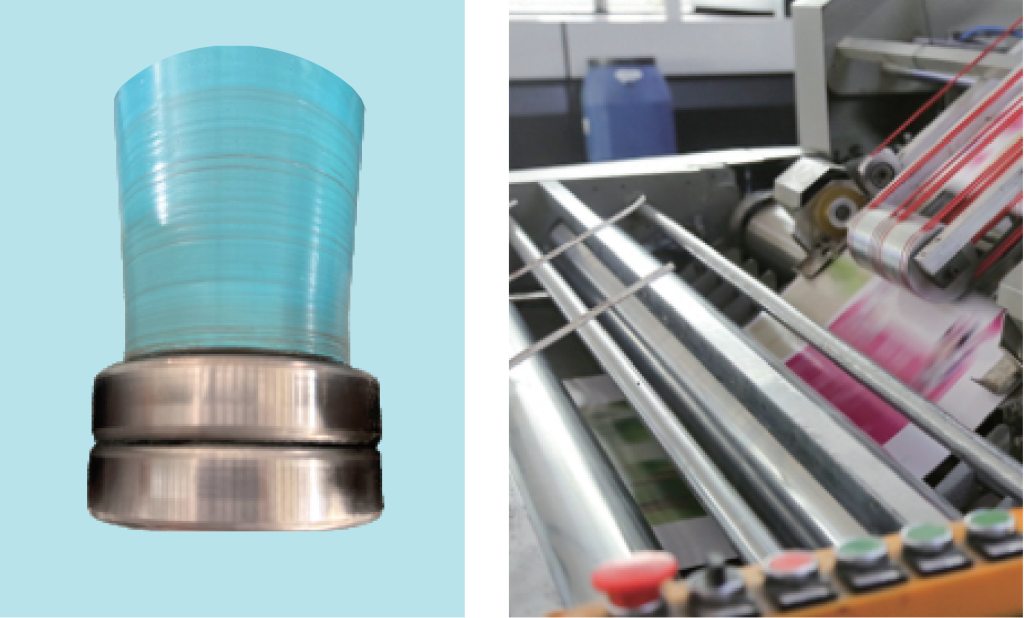

PU Bottom Feeding Wheel

- Unidirectional rotating feeding roller, without wear and tear, service life cycle up to 10 years.

Leading-edge Feed System

- Self-developed leading-edge feed system specially for deformed, warped corrugated papers.

One-button Operation

- Adopting 7-8 servo motors control systems, digital intelligent input, automatic order changeover in 2-3 min.

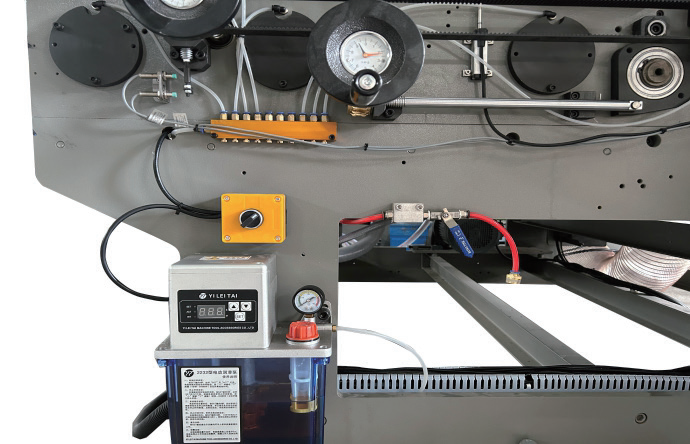

Automatic Lubrication of Bearings

- Intelligent control for automatic lubrication, no need for daily maintenance, saving labor costs, and improving production efficiency.

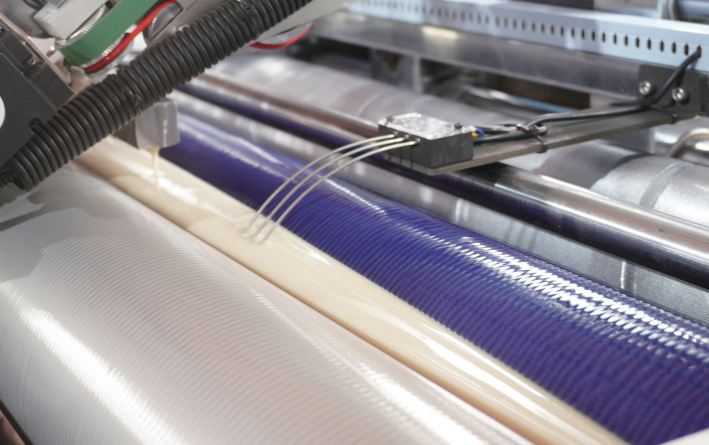

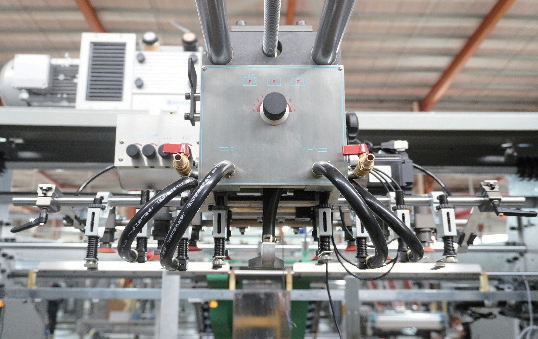

Enlarged Glue Roller

- Enlarged 150mm diameter stainless steel roller, laser engraved anilox, high-speed and stable without glue splashing.

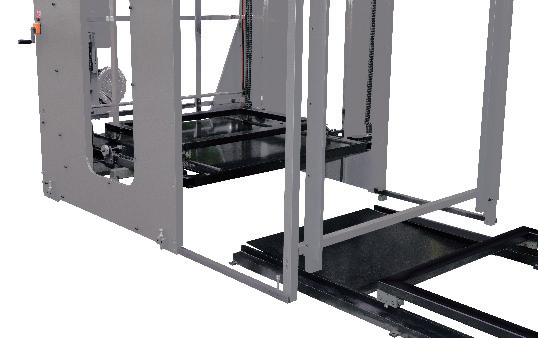

Servo Control Lifting Pile Plate

- High speed feeder smooth feeding, single sheet lifting same as offset printing press, high efficient and stable.

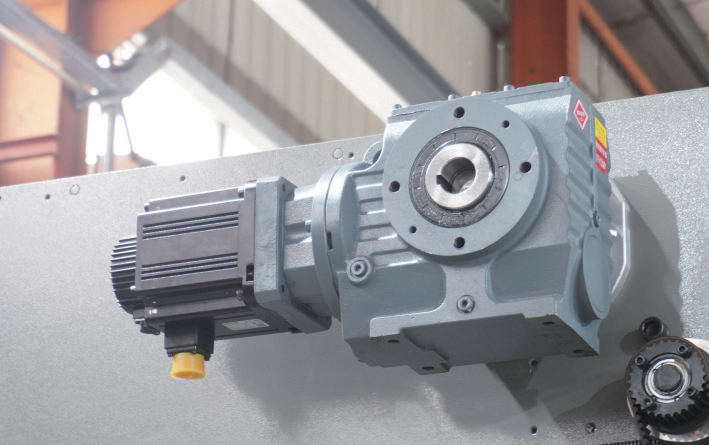

Dual-bearing Structure

- Ensures efficient and stable operation of the machine with doubled life cycle.

Pre-stacking System

- Whole pallet loading platform, saving labor costs and time.

Shaft-less High Speed Feeder

- Servo controlled high-speed shaft-less feeder front-and-rear auto-adjustment.

Why Partner with Fengchi?

High Quality

Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Vast Experience

More than 15 years of experience within automation gives us an enormous know-how and expertise in laminating solutions.

30 + Patents

We continuously push the boundaries of speed and performance, securing 30 patents through independent research and development.

Global Support

We proudly export corrugated laminating solutions worldwide, ensuring international clients benefit from our innovative technology.

What Our Customers Say

Hear from industry leaders who have transformed their production with our automatic flute laminators

We’ve increased our daily output by 45% while reducing material waste. The ROI was achieved in just 10 months.

– John Smith, Production Manager

The technical support is exceptional. When we had a minor issue, their team resolved within 24 hours.

– Maria Johnson, Operations Director

The precision and consistency of the flute laminator have significantly improved our product quality.

– Robert Williams, CEO

Trusted by Industry Leaders

Major Suppliers

First Class Service & Support

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines. Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

Request a Quote

Speak with one of our experts today for a personalized consultation and quote.