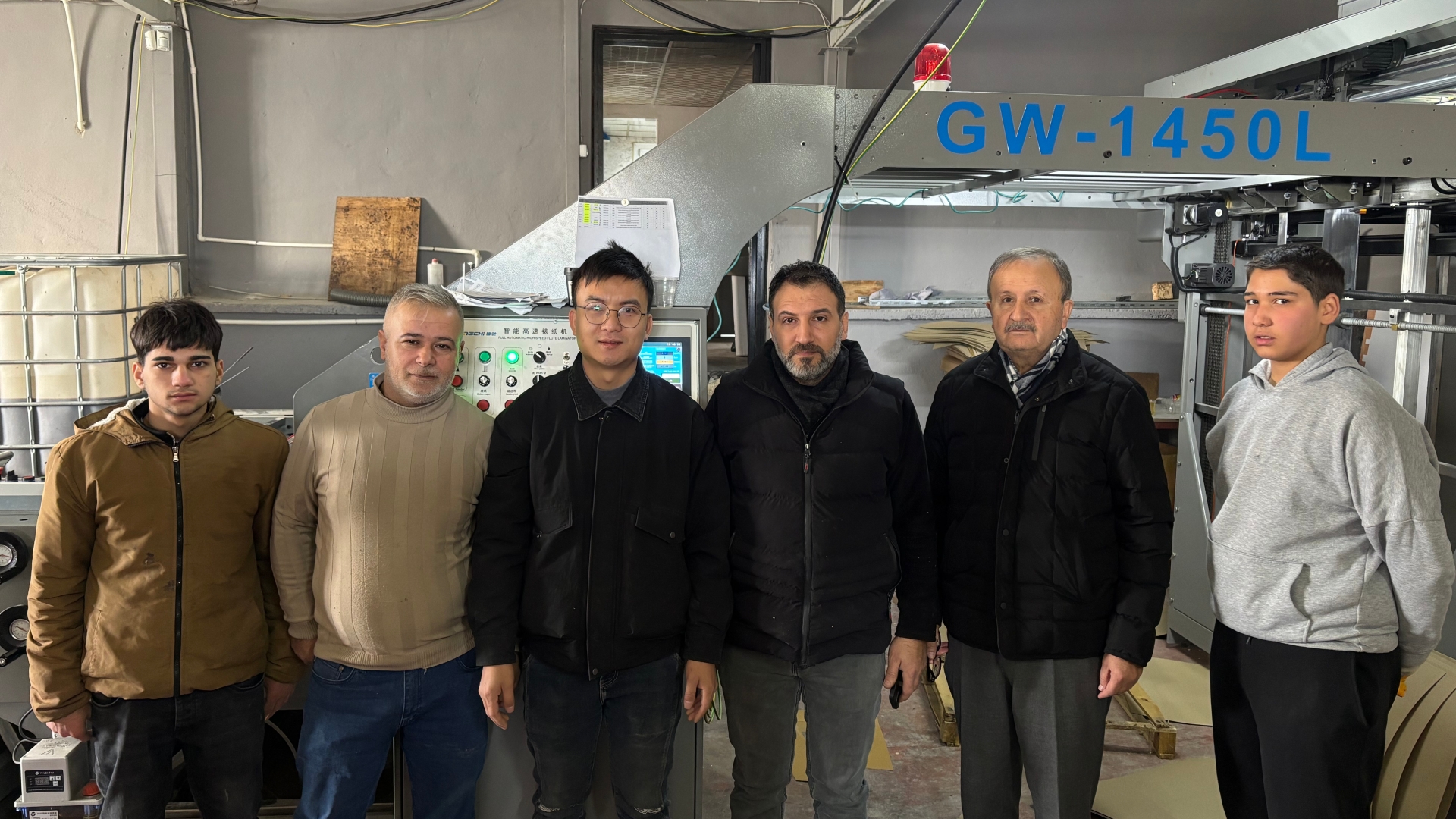

When packaging deadlines tighten and order volumes climb, the right equipment can turn a bottleneck into a competitive edge. Last week Fengchi’s after-sales engineers completed the installation and commissioning of a full flute laminating production line for a client — featuring the GW-1700L high-speed flute laminator and the FZ-1700 flip-flop stacker. The result: smooth startup and test results of 8,530 sheets per hour on standard test substrates — a real-world increase in packaging production efficiency.

What was installed and why it matters

The production line delivered to the client included:

- GW-1700L high-speed flute laminator — designed for continuous, heavy-duty operation and high output.

- FZ-1700 flip-flop stacker — engineered to reliably stack laminates for downstream handling and finishing.

Together these machines form a turnkey solution for corrugated board laminating lines. For packaging manufacturers, this kind of integration reduces manual handling, reduces cycle time, and increases usable output — which translates directly into faster order turnaround and improved margins.

Test conditions & verified performance

Fengchi’s engineers tested the line using:

- Base material: 950 mm × 450 mm E-flute corrugated board

- Face material: 950 mm × 450 mm white cardboard

- Achieved laminating speed (test): 8,530 sheets/hour

These test conditions reflect a typical packaging production scenario and demonstrate consistent, high-throughput laminating capability when paired with the FZ-1700 stacker for efficient downstream stacking.

GW-1700L: speed, stability, and 24/7 reliability

The GW-1700L is positioned as a high-capacity workhorse:

- Maximum speed: 22,000 sheets/hour

- Stable continuous output: around 16,000 sheets/hour

- Designed for: continuous 24/7 operation

That operational profile makes the GW-1700L an ideal choice for high-volume printing and packaging manufacturers who need dependable throughput under heavy schedules. More than a piece of equipment, it’s a strategic investment that supports scaling production without frequent downtime.

Why pairing with an FZ-1700 flip-flop stacker matters

Laminating speed is only as valuable as the downstream handling that supports it. The FZ-1700 flip-flop stacker ensures sheets are stacked quickly and accurately as they exit the laminator, preventing bottlenecks and protecting finished surfaces. The combined line reduces manual intervention and preserves sheet quality at high speeds.

Real benefits for packaging operations

Installing a modern flute laminating line delivers several measurable advantages:

- Increased hourly output and the ability to meet larger contracts

- Lower labor costs through automation and reduced manual handling

- Improved consistency and fewer rejects thanks to stable laminating parameters

- Better lead-time reliability for customers and faster order fulfilment

About Fengchi Printing Machinery

Fengchi specializes in automatic flute laminators and flip-flop stackers tailored for the printing and packaging industries. From selection and installation to commissioning, service, and maintenance, Fengchi supports customers through the entire lifecycle of their laminating solution.

Ready to boost your packaging production?

If you are looking to increase your laminating speed, improve product quality, and strengthen your competitive advantage, Fengchi has the solution.

Tell us about your project! Our experts are here to help you find the perfect flute laminating machine for your needs.

Contact Us Today to get started and let’s discuss how we can optimize your production line.

FAQ

Q: What throughput can the GW-1700L achieve?

A: Maximum speed is 22,000 sheets/hour with a stable continuous output around 16,000 sheets/hour.

Q: Can the GW-1700L run 24/7?

A: Yes — it’s designed for continuous 24/7 operation when maintained properly.

Q: What substrates can the GW-1700L process?

A: A, B, C, E, F, 3ply, 5ply, 7ply corrugated board, and cardboard.

Q: Why add a flip-flop stacker?

A: The FZ-1700 ensures fast, accurate stacking to match high laminating speeds and minimizes handling damage.

Q: How do I get a quote or schedule an installation?

A: Contact Fengchi with your substrate sizes, target speed, and production goals — the team will recommend a line configuration and provide a quote.

See how Fengchi’s GW-1700L high-speed flute laminator and FZ-1700 flip flop stacker increased a client’s packaging production efficiency. Achieve laminating speeds of 16,000+ sheets/hour.