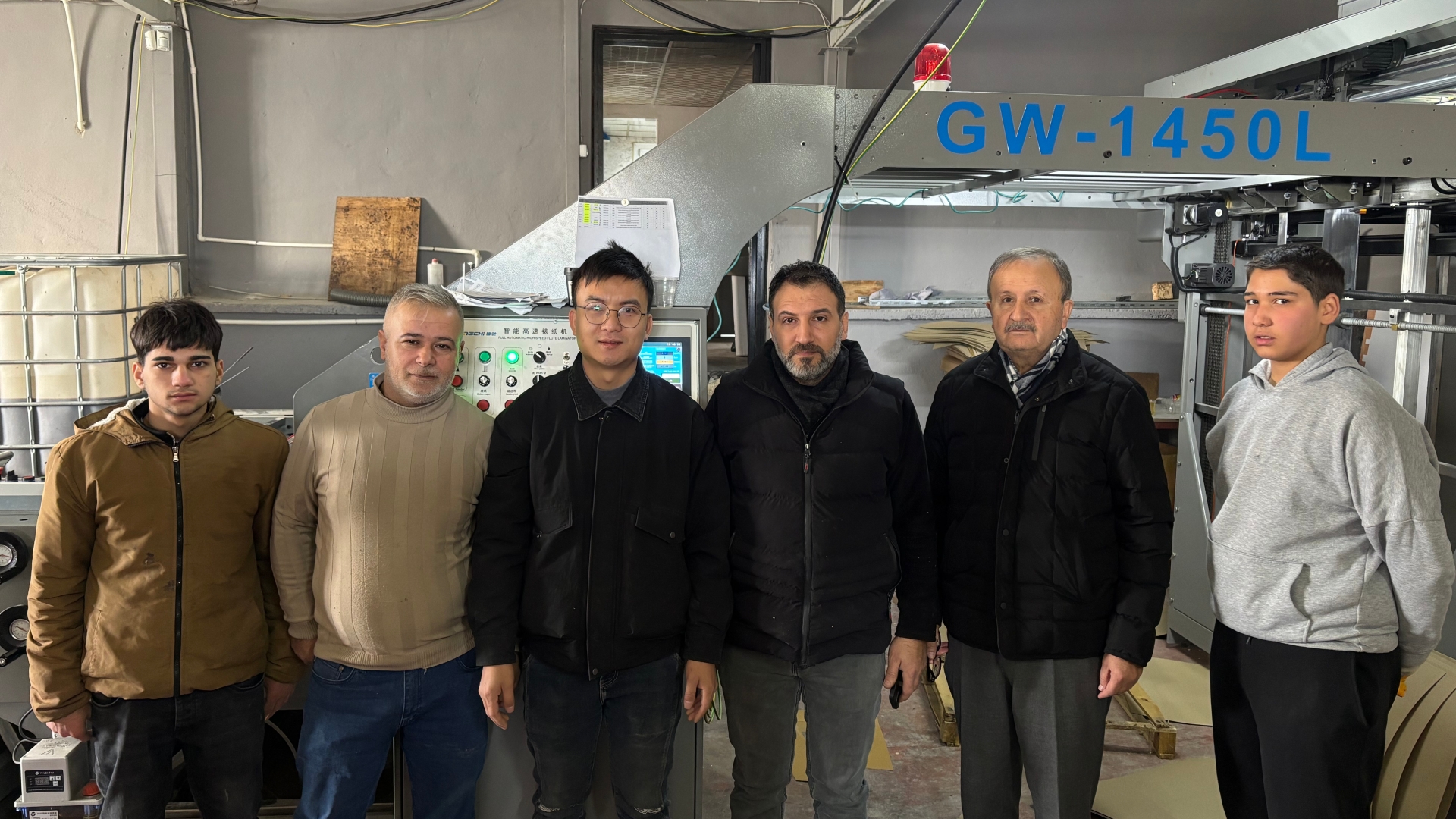

In September 2025 Fengchi Printing Machinery’s senior after-sales engineer traveled to Iran to install and commission the GW-1450L high-speed litho laminator for a packaging customer producing bread boxes. The onsite commissioning confirmed the GW-1450L’s reputation for high throughput, reliability, and operator-friendly automation — delivering measurable productivity gains from day one.

Commissioning results — tested materials and real production speed

During commissioning the GW-1450L was tested on practical production inputs:

- Base paper dimensions: 1055 mm × 850 mm

- Face paper weight: 170 gsm

- Achieved production speed: 10,632 sheets per hour

This real-world result met the customer’s expectations and demonstrated the machine’s ability to handle high-volume litho lamination for specialty packaging such as bread boxes.

Comprehensive operator training — independence in one week

Fengchi engineers provided hands-on, comprehensive training to the Iranian client’s laminator operators. Training covered:

- Safe start-up and shutdown procedures

- Full operation of the GW-1450L control systems and automation features

- Daily maintenance checks and routine upkeep

- Basic troubleshooting and performance optimization

After approximately one week, the operators had mastered machine operation and daily maintenance tasks and were capable of running the line independently. Only after confirming operator competence did Fengchi formally conclude the training program.

After-sales support — fast, flexible, and customer-first

Fengchi’s service model emphasizes rapid response and practical support:

- Remote assistance via virtual video guidance or remote troubleshooting for most issues

- On-site technician dispatch for complex repairs or component replacement

- A global network of trained agents and service centers to ensure minimal downtime

This combination of remote and on-site support ensures that the GW-1450L remains highly available and productive long after installation.

Why customers choose the GW-1450L and Fengchi machines

Fengchi machines are widely recognized for:

- Robust construction and dependable durability

- User-friendly design and high degrees of automation and intelligence

- Low maintenance requirements — effectively minimizing operational interruptions

- Broad international adoption: Fengchi equipment is distributed and serviced across 60+ countries, backed by subsidiaries and sales centers in Turkey, Indonesia, and Thailand.

For the Iranian customer, the GW-1450L represented more than a single piece of equipment — it was a strategic investment designed to elevate corrugated cardboard lamination capabilities and accelerate business growth.

Benefits for packaging producers (bread boxes and beyond)

Packaging manufacturers who choose the GW-1450L can expect:

- Higher throughput and consistent quality for litho-laminated board products

- Reduced labor and maintenance overhead thanks to automation

- Faster ramp-up time through structured operator training programs

- Local and remote support that protects uptime and production targets

Ready to upgrade your production line?

If you’re producing packaging like bread boxes and want a proven litho laminator that combines speed, reliability, and low maintenance, the GW-1450L is a strong candidate. Connect with Fengchi’s experts to discuss material trials, site commissioning, and tailored operator training plans.

FAQ

Q: What speed did the GW-1450L achieve during commissioning in Iran?

A: The GW-1450L produced 10,632 sheets per hour on 170gsm face paper (base paper 1055 mm × 850 mm).

Q: How long did operator training take?

A: Comprehensive operator training lasted about one week, after which operators could run the machine independently.

Q: What support does Fengchi provide after installation?

A: Fengchi offers remote troubleshooting via video, virtual guidance, and on-site technician dispatch when needed — supported by agents in over 60 countries.

Discover how Fengchi’s GW-1450L high-speed litho laminator boosted a client’s production in Iran. Learn about our reliable machinery, global support, and commitment to customer success.