In the competitive world of product packaging, the ability to let consumers see the item inside can be a decisive sales advantage. This “try-before-you-buy” visual experience is made possible by advanced window patching technology. Leading this innovation is ONEZIM, China’s premier manufacturer of automatic window patching machines, recently demonstrating its expertise with a successful high-speed machine installation that met all client expectations for quality and speed.

What is a window patching machine — and why it matters?

Window patchers automatically apply transparent film to pre-cut window openings in cardboard or corrugated board so consumers can see the product inside the box. For brands this delivers:

- Improved shopper confidence (visible product)

- Stronger shelf appeal and higher conversion rates

- Faster, more consistent production vs. manual film application

ONEZIM’s equipment supports die-cutting, gluing and film application in a seamless automated flow.

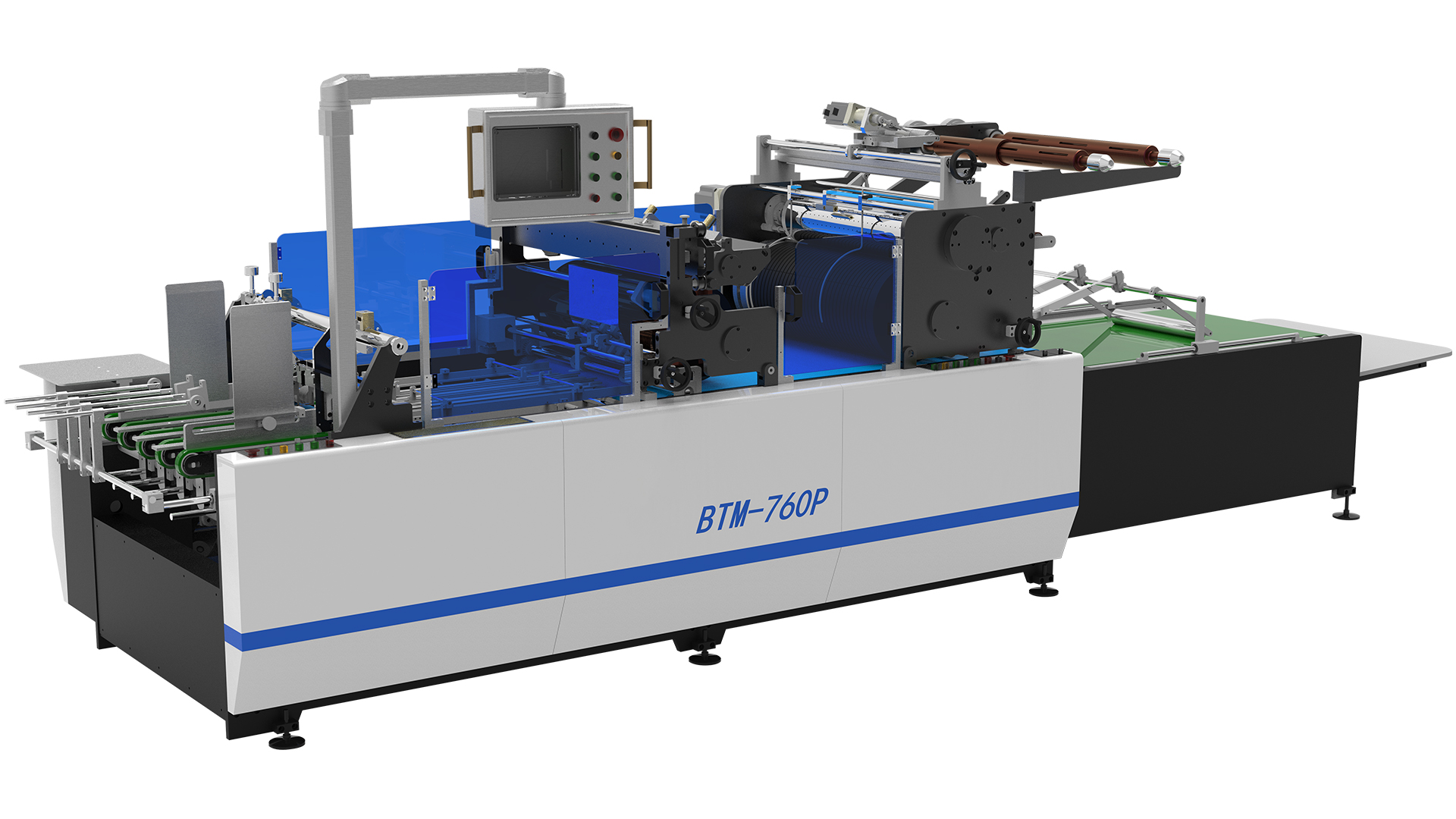

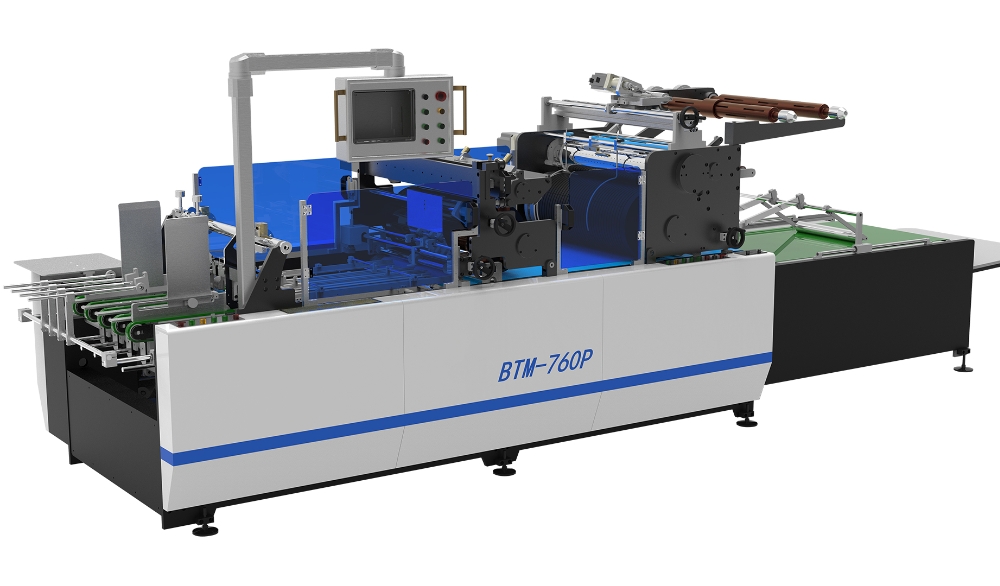

Model P Series — Designed for high-volume tissue box production

The Model P Series is a fully automatic, high-speed flat window patcher engineered for manufacturers who need speed and precision.

Key specs & performance

- Maximum output: 36,000 sheets/hour (200 m/min)

- Continuous operation: 32,000 sheets/hour (185 m/min) for 24/7 production runs

- Application accuracy: ±1.0 mm film placement (full servo bus + proprietary control)

- Durability: Servo motors and drives designed with a 35% load margin for >15 years of reliable service

- Drive system: Nine coordinated servo motors for smooth, intelligent operation

Smart features

- Smart sheet collection with integrated counting for non-glued products

- Fully digital setup: one-touch adjustments for feeding, gluing, laminating, and cutting — minimal setup time

- Custom window sizes: Models support windows up to 1400mm × 1400mm; bespoke layouts available on request

- Safety & compliance: All automatic models carry CE certification

Business benefits

- Scale quickly to meet large orders without sacrificing quality

- Lower scrap/waste thanks to precise film placement and consistent glue control

- Reduce labor costs and guaranteed repeatability across shifts

- Faster time-to-market for new SKUs because of digital, repeatable setups

Typical industries & applications

ONEZIM window patchers are used across consumer packaging categories:

- Tissue & facial tissue boxes

- Cosmetics & beauty packaging

- Food packaging (where display windows are permitted)

- Gift boxes and premium packaging

- Toys, consumer electronics and small appliances

Ready to join ONEZIM’s global agent network

ONEZIM is actively expanding its global network and seeking agents to bring this innovative high-speed window patching technology to new markets. If you are interested in representing a top-tier equipment manufacturer or integrating ONEZIM’s machines into your packaging line, the company offers robust support policies to help you achieve greater commercial success.

Ready to transform your packaging efficiency and product appeal? Contact ONEZIM today to learn more about our machines and distributor opportunities.

Short FAQ

Q: What substrates can it handle?

A: Flat cardboard and corrugated board used for tissue, cosmetics, food and general packaging (custom substrate requests supported).

Q: Is the machine suitable for 24/7 production?

A: Yes — designed for continuous operation (32,000 sheets/hr continuous rating).

Q: Can ONEZIM customize window sizes?

A: Yes — standard models support up to 1400mm × 1400mm and custom solutions are available.

ONEZIM’s Model P Series high-speed window patching mach…