Flip Flop Stacker

Automatic flip flop stacker for high-speed flute laminators — precision servo control,

stable operation, and labor-saving performance.

Flip Flop Stacker

As an auxiliary equipment for high-speed flute laminator

Why Choose the Flip Flop Stacker?

Servo Precision

Full-servo control ensures accurate front-back stacking alignment, reducing rejects and improving consistency.

Seamless Integration

Designed to synchronize with full-servo flute laminators — seamlessly integration for smooth production flow.

Labor-Saving Efficiency

Automatic flipping and stacking reduce manual handling, improving throughput and operator safety.

Advanced Features & Performance

Built for precision, stability, and productivity — engineered to meet the demands of modern packaging lines.

- Full-servo motion control: Bus control with multiple servo axes for precise pile positioning.

- Flip-flop pile turning: Alternating stack direction to prevent curling and improve palletizing.

- Auto counting sensors: Accurate pile height and automatic stop for consistent stacking.

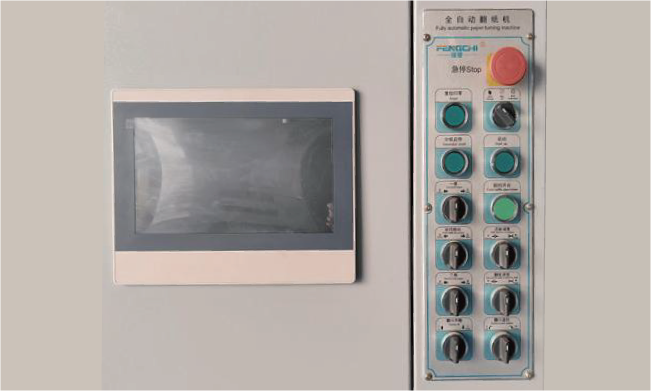

- Touchscreen HMI: Easy operation with programmable sheet size and pile height.

Technical Specifications

| Parameter / Model | FZ-1450 | FZ-1700 | FZ-2200 |

|---|---|---|---|

| Max Sheet Size(mm) | 1450 × 1450 | 1700 × 1650 | 2100 × 1650 |

| Min Sheet Size(mm) | 500 × 380 | 550 × 380 | 600 × 380 |

| Max Speed(sheets/hr) | Up to 15,000 | Up to 15,000 | Up to 15,000 |

| Weight(kg) | 3,800 | 4,000 | 5,600 |

| Dimension (L × W × H)(mm) | 6955 × 2432 × 2892 | 7555 × 2682 × 2892 | 9120 × 2910 × 2892 |

| Power(kW) | 12 | 12 | 14 |

| Voltage | 380VAC/3P | 380VAC/3P | 380VAC/3P |

| Gas Source | 0.8Mpa>5.5kW | 0.8Mpa>5.5kW | 0.8Mpa>5.5kW |

Note: All specifications are subject to change without notice. Please contact us for the most current information.

Product Gallery

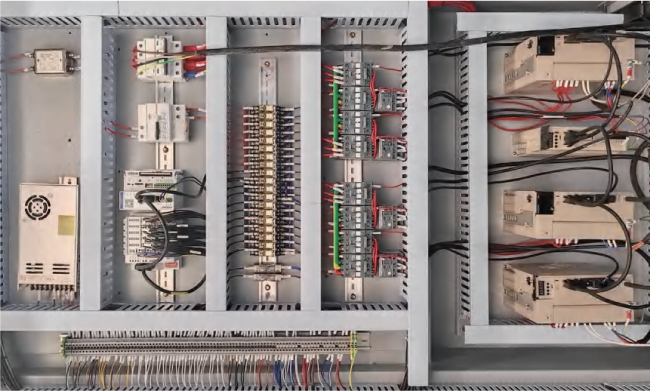

Electrical Control System

- The system adopts internationally advanced motion control technology and digital control, ensuring smoother, faster, and more stable machine operation with easier usability.

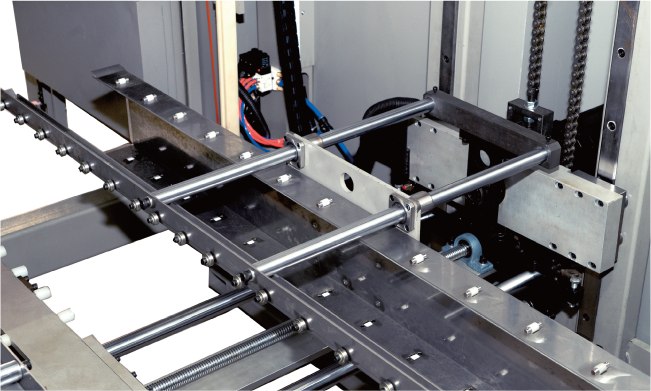

Pile Turning Mechanism

- Adopting high-speed silent track which is smooth, silent, wear-free, and with long-term service life. The flipping servo and lifting servo electronic cam are locked, the flipping lifting speed can be adjusted disposable.

Lubrication

- Adopting simple man-machine interface which only needs to input the paper size, one key to adjust the machine, no need to use any tools, one key to start. The equipment adopts operation control technology.

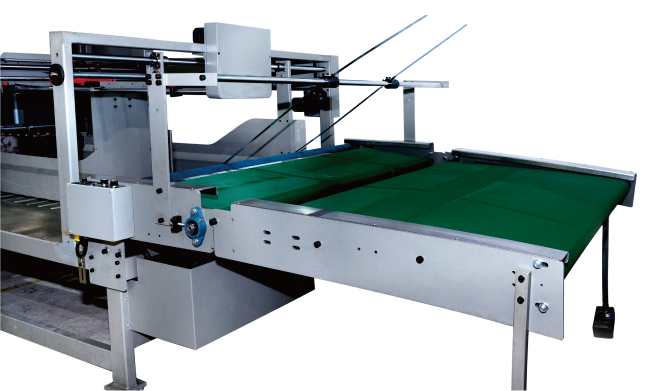

Paper Division

- The three-section independent frequency conversion speed regulation mechanism can adjust the speed of each section of the paper according to the thickness of the paper output from the main machine press.

Why Partner with Fengchi

High Quality

Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Vast Experience

More than 15 years of experience within automation gives us an enormous know-how and expertise in laminating solutions.

30 + Patents

We continuously push the boundaries of speed and performance, securing 30 patents through independent research and development.

Global Support

We proudly export corrugated laminating solutions worldwide, ensuring international clients benefit from our innovative technology.

What Our Customers Say

Fengchi provides confidence, reliability and consultancy no matter the scope of the project. Experienced and customer focused, they provide tailored solutions.

– Mark Jensen, Sales Agent

Fengchi have been a pleasure to work with, not a single detail was missed and the project was delivered on time and on budget. l look forward to working with them again.

– David Lee, Owner

Our laminated corrugated board production soared after installing Fengchi’s high-speed flute laminators. Precision and speed are unmatched.

– Sarah Chen, Operations Director

Trusted by Industry Leaders Worldwide

Major Suppliers

First Class Service & Support

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines.

Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

Frequently Asked Questions

What is the max speed of the flip flop stacker?

Up to 15,000 sheets/hour depending on model and substrate.

What materials can the stacker handle?

A, B, C, E, and F flutes, as well as multi-ply corrugated cardboard.

How easy is changeover?

Touchscreen presets reduce changeover time significantly; exact time depends on operator training and job complexity.

What warranty/support?

Standard 12-month warranty; global spare parts and service available.

Can it integrate with my litho laminator?

Yes — drop-in integration with major laminator lines via sync signal.

Delivery & lead time?

Typical lead time: 10–30 days (confirm per order). The specific delivery time depends on the product and the order quantity.

Will you supply for OEM orders?

Yes, we can customize the production machine according to your requirements.

Interested in a full servo flip flop stacker?

Contact Form

Phone