Introduction — Why the right litho laminator matters for packaging

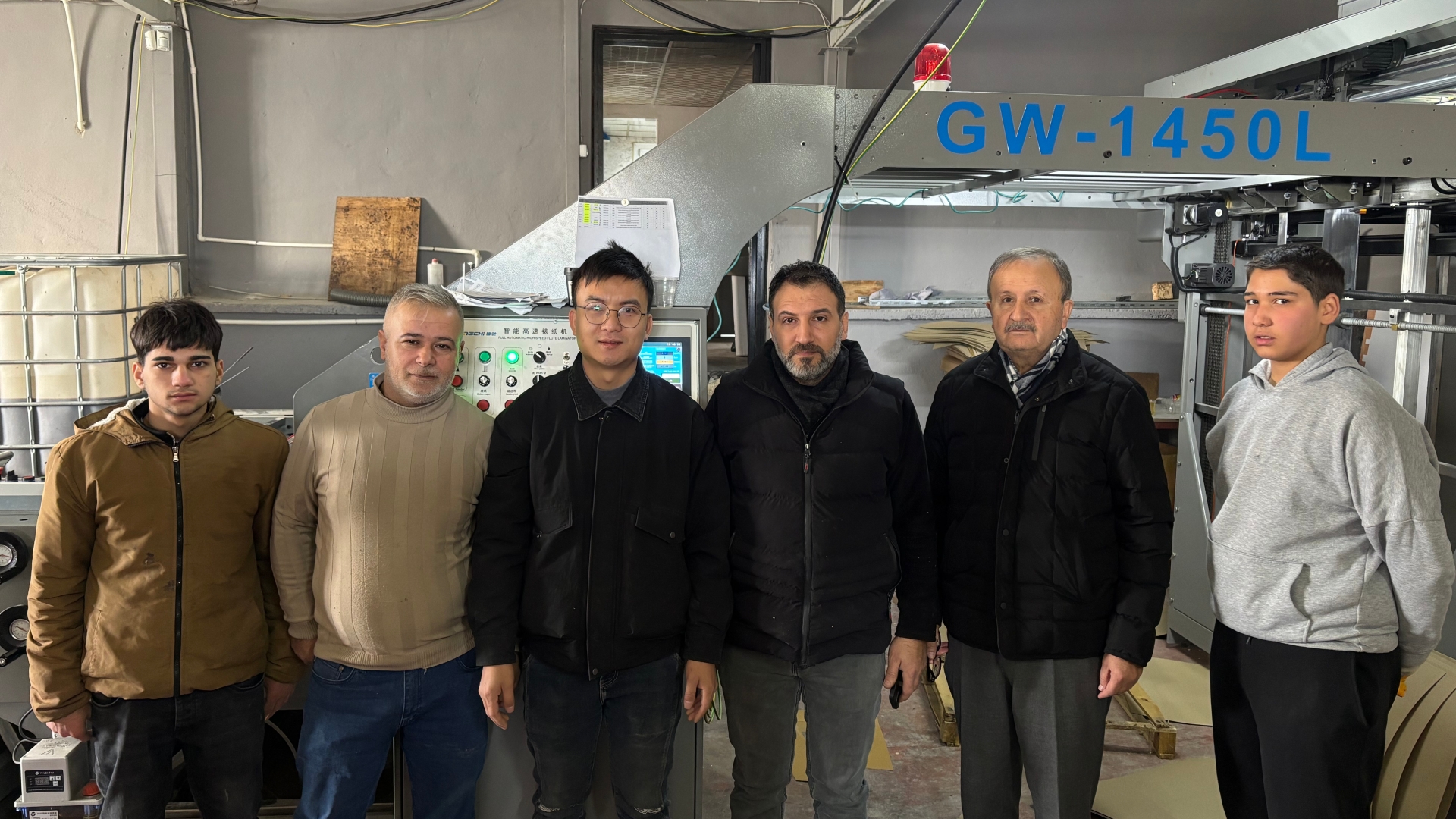

Fengchi Printing Machinery recently carried out in-depth factory visits to customers using our sheet-to-sheet litho laminators to collect real-world feedback and to evaluate on-site performance. One standout visit was to a large corrugated color-box and cardboard packaging plant in Rizhao, Shandong — a 7,000 m² facility with monthly turnover exceeding RMB 5 million. The plant has relied on Fengchi litho laminators as their first post-printing process for over three years, running at up to 16,000 sheets per hour to meet heavy order volumes.

Customer spotlight: Rizhao factory performance and benefits

This Rizhao facility is representative of how modern packaging converters scale using advanced post-press automation:

- Large throughput: With orders driving speeds up to 16,000 sheets/hour, the plant keeps lead times short while maintaining consistent finish quality.

- Reliable uptime: Three years of continuous production with Fengchi equipment shows durability and dependable service.

- Scalable quality: The laminator’s automated controls ensure stable glue application and ±1 mm registration accuracy so printed graphics align perfectly with corrugated substrates.

- Wider market reach: Efficient post-press enabled the factory to expand service across neighboring cities.

What is a sheet-to-sheet litho laminator?

For those new to the process, a sheet-to-sheet litho laminator is a cornerstone of modern corrugated packaging production. It expertly bonds pre-printed paper to corrugated cardboard, creating a strong, high-quality laminated sheet ready to be converted into sturdy, visually appealing boxes. This process is essential for producing the vibrant, retail-ready packaging seen across countless industries.

Product spotlight — Fengchi sheet-sheet litho laminator (key specs)

Our sheet-sheet litho laminator is engineered for high-volume packaging converters:

- Max speed: 175 m/min (up to 22,000 sheets/hour theoretical peak)

- Typical customer operation: up to 16,000 sheets/hour in high-order environments

- Registration accuracy: ±1 mm

- Glue consumption: 18–20 gsm per m²

- Controls & options: Digital PLC control; optional automatic flip-flop stacker; robust laminating unit and conveyor system for corrugated and pre-printed sheets

These features translate into consistent laminated offset boards, fast turnovers, and lower waste.

Fengchi & ONEZIM: Your partner in automated post-press solutions

Our commitment to innovation continues through our subsidiary brand, ONEZIM, which provides comprehensive automated post-press solutions.

Our expanded product portfolio includes:

- High Speed Litho Laminators

- Flip Flop Stackers

- Folder Gluer Stitchers

- Spot UV Coating Machines

- Window Patching Machines

We offer turnkey solutions — from complete line installations and upgrades to on-site training and global after-sales support.

Why converters choose Fengchi

- 15+ years of industry experience designing and manufacturing sheet-sheet litho laminators.

- Custom and standard solutions tailored for different substrates, speeds, and production footprints.

- Global support & training to help customers squeeze maximum efficiency from their lines.

- Proven ROI — faster throughput, fewer defects, and predictable glue usage.

Applications & ideal customers

Fengchi sheet-to-sheet laminators fit converters who need:

- High-volume color box and corrugated tile production

- Tight registration and high visual quality for printed packaging

- Automated end-of-line stacking and minimal manual handling

- Reliable glue usage control and low setup times

Join our global sales agent network

Fengchi is actively seeking sales agents worldwide to expand our reach and bring our reliable packaging solutions to new markets. If you are interested in joining our global sales network, we invite you to contact our sales team today to discuss partnership opportunities.

Choose Fengchi—where proven performance meets global support.

Discover how Fengchi’s sheet-to-sheet litho laminators improve speed, accuracy and quality — showcased at a major Rizhao corrugated color-box factory.