Flute Laminating Line

Engineered for unparalleled speed, accuracy & reliability.

Runs up to 22,000 sheets/hour with laminating accuracy ±1.0 mm.

Flute Laminating Line

High-speed litho laminating line for corrugated and cardboard packaging.

Overview

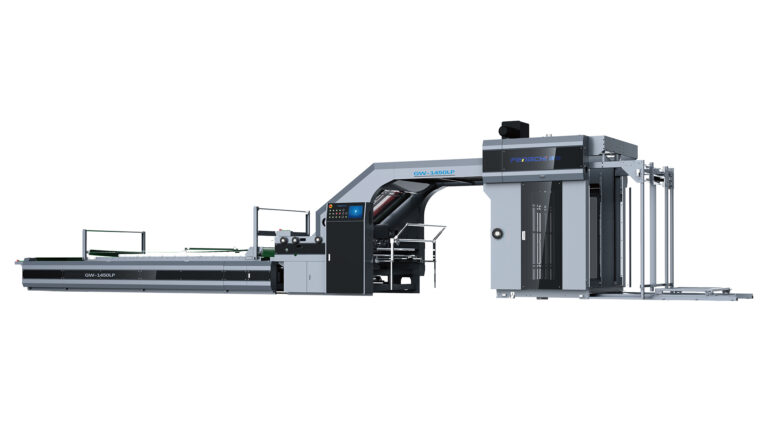

Automatic flute laminator machine production line

Fengchi Printing Machinery is a leader in high-speed flute laminator machines, with over 15 years of R&D in intelligent, digital, automated, energy-efficient, and eco-friendly solutions.

The flute laminating machine production line consists of a full servo high-speed flute laminating machine and a flip-flop stacker, helping corrugated packaging manufacturers improve efficiency and productivity.

Our high-speed flute laminating machine line feature:

12 servo motors with bus control for ultra-stable, precise operation

Fully integrated laminating, turning, and paper collection

Intelligent control system that maximizes post-press laminating capacity

Would you like to learn more about this product? Please contact us today.

See Flute Laminator Line in Action

Automatic flute laminating production line designed for reliability and speed

Choose Your Model

At Fengchi Printing Machinery, we offer a wide range of high-speed flute laminator lines to meet your production needs.

GW-1450LP Automatic flute laminator machine production line

Model: GW-1450LP

Automatic Grade: Automatic

Membrane Material: Paper

Performance: Anticorrosive

Patent: Leading Edge Paper Feeding Patent

Max. Speed: 22,000 Sheets/Hour

Advantages: Low Failure Rate, High Efficiency, Long Life

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

GW-1700LP Automatic flute laminator machine production line

Model: GW-1700LP

Automatic Grade: Automatic

Membrane Material: Paper

Performance: Anticorrosive

Patent: Leading Edge Paper Feeding Patent

Max. Speed: 22,000 Sheets/Hour

Advantages: Low Failure Rate, High Efficiency, Long Life

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

GW-2200LP Automatic flute laminator machine production line

Model: GW-2200LP

Automatic Grade: Automatic

Membrane Material: Paper

Performance: Anticorrosive

Patent: Leading Edge Paper Feeding Patent

Max. Speed: 22,000 Sheets/Hour

Advantages: Low Failure Rate, High Efficiency, Long Life

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

GW-1450BP Automatic flute laminator machine production line

Model: GW-1450BP

Automatic Grade: Automatic

Membrane Material: Paper

Performance: Anticorrosive

Patent: Belt feeder version

Max. Speed: 22,000 Sheets/Hour

Advantages: Low Failure Rate, High Efficiency, Long Life

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

GW-1700BP Automatic flute laminator machine production line

Model: GW-1700BP

Automatic Grade: Automatic

Membrane Material: Paper

Performance: Anticorrosive

Patent: Belt Feeder Version

Max. Speed: 22,000 Sheets/Hour

Advantages: Low Failure Rate, High Efficiency, Long Life

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

GW-2200BP Automatic flute laminator machine production line

Model: GW-2200BP

Automatic Grade: Automatic

Membrane Material: Paper

Performance: Anticorrosive

Patent: Belt Feeder Version

Max. Speed: 22,000 Sheets/Hour

Advantages: Low Failure Rate, High Efficiency, Long Life

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

* Not sure which flute laminator machine is best suited to your needs? Contact our experts.

High-speed Flute Laminator

Technical Specifications

| Model | GW-1450LP / GW-1450BP | GW-1700LP / GW-1700BP | GW-2200LP / GW-2200BP |

|---|---|---|---|

| Max. Paper Size (W x L) | 1450 x 1450 mm | 1700 x 1650 mm | 2200 x 2100 mm |

| Min. Paper Size (W x L) | 360 x 360 mm | 360 x 360 mm | 450 x 380 mm |

| Bottom Paper Sheet Thickness | F flute-10mm | ||

| Upper Paper Sheet Thickness (W x L) | 150 g-700 g | ||

| Max. Working Speed | 22,000 Sheets/Hour (175 M/Min) | ||

| Laminating Accuracy (W x L) | ±1.0mm (Standard Sheet Paper) | ||

| Applicable Glue | Resin adhesive, starch glue and etc ( PH6~8 will be suitable ) | ||

| Power Supply | 380 VAC/3P | ||

| Power | 26 kW | ||

| Applicable Corrugated Board | A, B, C, E, F, 3ply, 5ply, 7ply corrugated board, and cardboard within above mentioned thickness range | ||

| Machine Weight | 8,000 KG | 8,500 KG | 9,000 KG |

| Overall Dimension (L x W x H) | 15,700 x 2,400 x 2,550 mm | 16,300 x 2,650 x 2,550 mm | 18,500 x 3,050 x 2880 mm |

* This is the current configuration. It may be updated as technology evolves.

Flute Laminator Machine Gallery

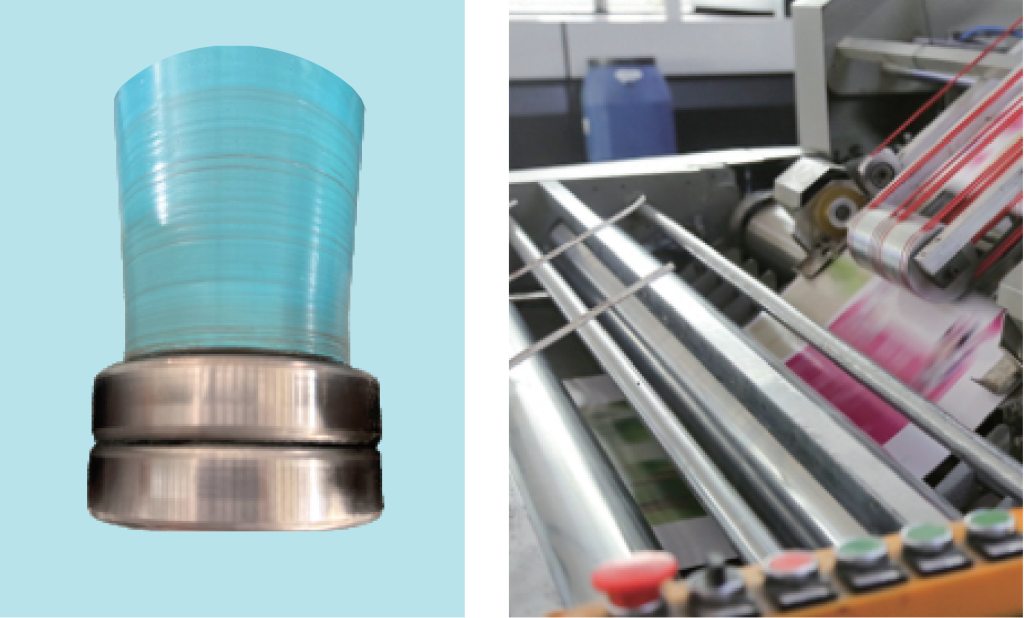

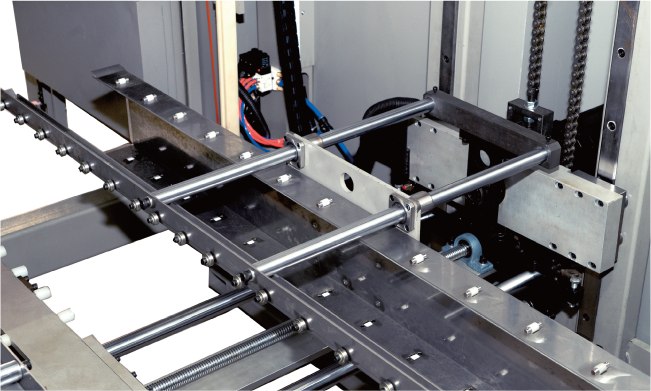

PU Bottom Feeding Wheel

- Unidirectional rotating feeding roller, without wear and tear, service life cycle up to 10 years.

Leading-edge Feed System

- Self-developed leading-edge feed system specially for deformed, warped corrugated papers.

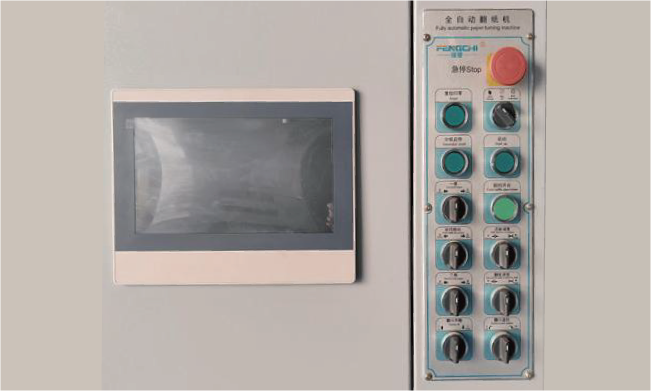

One-button Operation

- Adopting 7-8 servo motors control systems, digital intelligent input, automatic order changeover in 2-3 min.

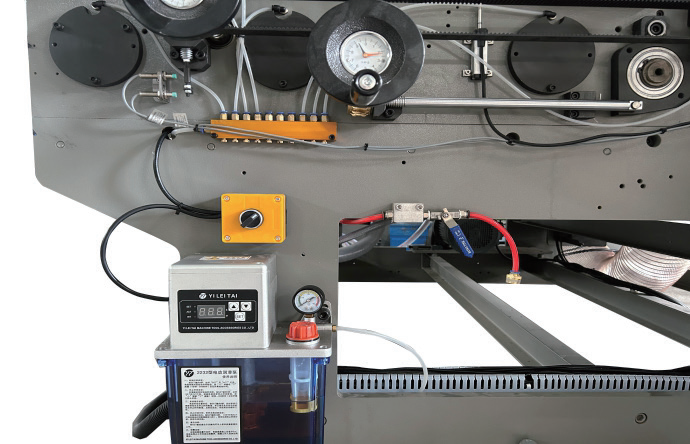

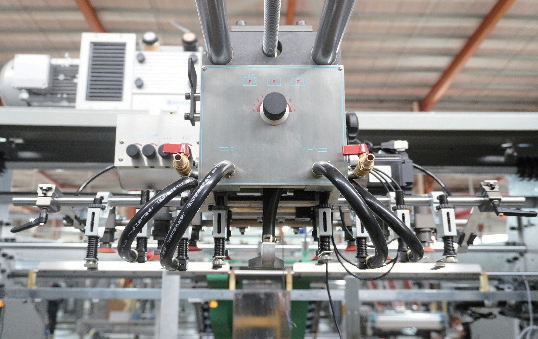

Automatic Lubrication of Bearings

- Intelligent control for automatic lubrication, no need for daily maintenance, saving labor costs, and improving production efficiency.

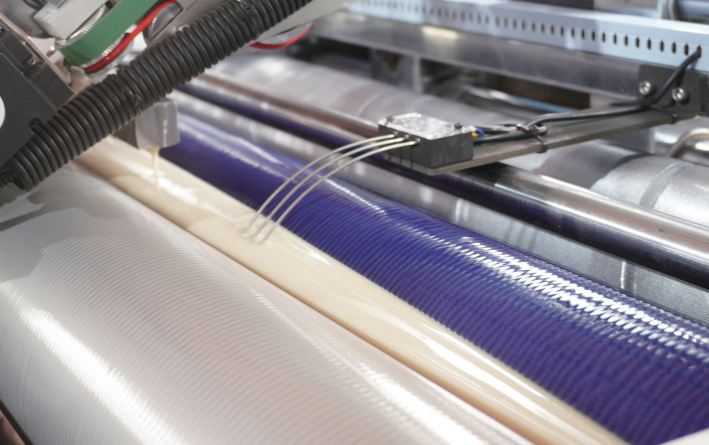

Enlarged Glue Roller

- Enlarged 150mm diameter stainless steel roller, laser engraved anilox, high-speed and stable without glue splashing.

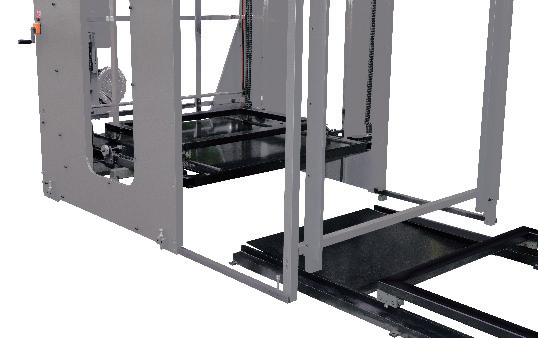

Servo Control Lifting Pile Plate

- High speed feeder smooth feeding, single sheet lifting same as offset printing press, high efficient and stable.

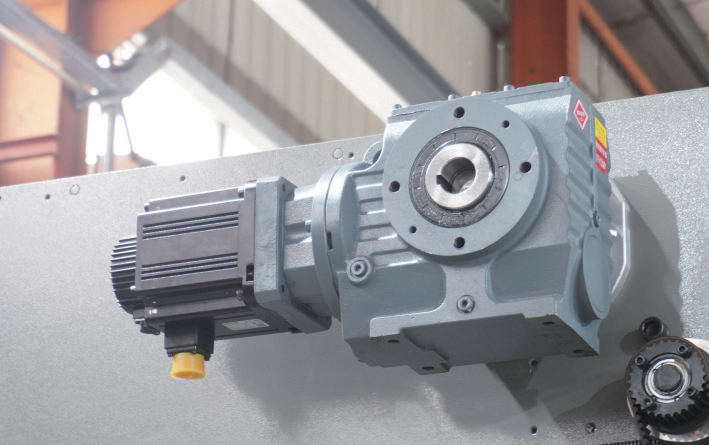

Dual-bearing Structure

- Ensures efficient and stable operation of the machine with doubled life cycle.

Pre-stacking System

- Whole pallet loading platform, saving labor costs and time.

Shaft-less High Speed Feeder

- Servo controlled high-speed shaft-less feeder front-and-rear auto-adjustment.

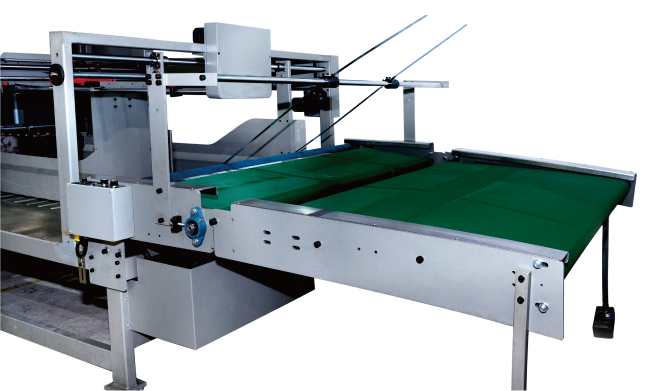

Flip Flop Stacker

Technical Specifications

| Model | FZ-1450 | FZ-1700 | FZ-2200 |

|---|---|---|---|

| Max.Sheet Size(W x L) | 1450 x 1450 mm | 1700 x 1650 mm | 2100 x 1650 mm |

| Min.Sheet Size (W x L) | 500 x 380 mm | 550 x 380 mm | 600 x 380 mm |

| Max. Working Speed | 15,000 sheets/hour | ||

| Machine Weight | 3,800 kg | 4,000 kg | 5,600 kg |

| Dimension (L x W x H) | 6,955 x 2,432 x 2,892 mm | 7,555 x 2,682 x 2,892 mm | 9,120 x 2,910 x 2,892 mm |

| Voltage | 380 VAC/3P | ||

| Power | 12 kW | 12 kW | 14 kW |

| Gas source | 0.8 MPa >5.5 kW | ||

* This is the current configuration. It may be updated as technology evolves.

Flip Flop Stacker Gallery

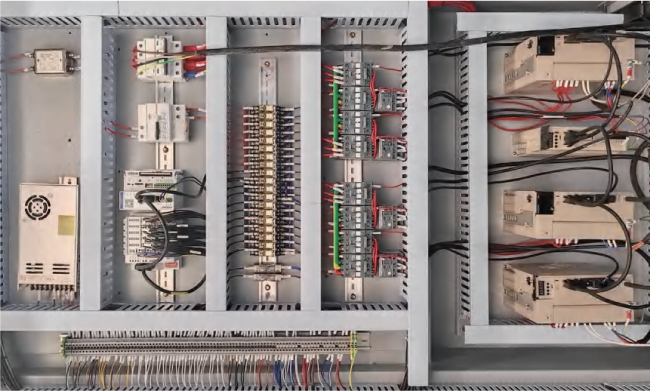

Electrical Control System

- The system adopts internationally advanced motion control technology and digital control, ensuring smoother, faster, and more stable machine operation with easier usability.

Pile Turning Mechanism

- Adopting high-speed silent track which is smooth, silent, wear-free, and with long-term service life. The flipping servo and lifting servo electronic cam are locked, the flipping lifting speed can be adjusted disposable.

Lubrication

- Adopting simple man-machine interface which only needs to input the paper size, one key to adjust the machine, no need to use any tools, one key to start. The equipment adopts operation control technology.

Paper Division

- The three-section independent frequency conversion speed regulation mechanism can adjust the speed of each section of the paper according to the thickness of the paper output from the main machine press.

Why Partner with Fengchi?

High Quality

Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Vast Experience

More than 15 years of experience within automation gives us an enormous know-how and expertise in laminating solutions.

30 + Patents

We continuously push the boundaries of speed and performance, securing 30 patents through independent research and development.

Global Support

We proudly export corrugated laminating solutions worldwide, ensuring international clients benefit from our innovative technology.

What Our Customers Say

Hear from industry leaders who have transformed their production with our automatic flute laminators

We projected a 15-month ROI, but the 45% output increase and 18% waste reduction with the GW-1700BP got us there in 10 months. The machine has been running flawlessly for 18 months now.

– John Smith, Production Manager

The technical depth of Fengchi’s support is exceptional. Their engineers provided on-site training that empowered our team to handle routine maintenance independently.

– Maria Johnson, Operations Director

After installing the Fengchi high-speed flute laminator, our output increased by over 30% with improved bonding quality.

– Robert Williams, CEO

Trusted by Industry Leaders Worldwide

Major Suppliers

Our Service for Your Success

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines.

Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

Frequently Asked Questions

What makes Fengchi different from other flute laminator line manufacturers?

We specialize exclusively in flute laminating technology with 15+ years of focused innovation. Our 25-engineer R&D team holds 30 patents specifically for solving corrugated lamination challenges like glue waste and paper warping. Unlike general machinery manufacturers, we’ve dedicated our entire business to perfecting this specific technology.

What is your typical delivery time?

Most standard models ship in 10-30 working days after order confirmation. We maintain some stock models for quicker delivery—contact us for current availability. For custom configurations, delivery time depends on the specific modifications required, but we work efficiently to minimize lead times without compromising quality.

What warranty is provided?

Standard warranty is 12 months from shipping date. Warranty will be not valid if machine subject to misuse or accidental damage or operator’s error. During the valid time, we will supply spare parts. If you have any other questions, pls contact us and we will reply you through product’s photos and videos to make every detail clear. We also provide all lifetime warranty with paid service.

How about installation and training?

Normally, one operator can finish intallation in 2 hours with installation manual and video. If purchaser’s engineer travels at own cost to China, free training session. If engineer sent to purchaser’s factory, all travel cost paid by purchaser.

Can machines be customized?

Yes — tailored configurations are available through our sales engineers.

How do you ensure machine quality before shipment?

Every machine undergoes 100% functional testing and a full pilot run with materials similar to yours. We are CE certified for international safety standards. Our quality control process includes dozens of specific checkpoints covering mechanical, electrical, and operational parameters.

Request a Quote

Tell us about your production needs — we’ll send pricing, lead time, and machine recommendation within 24 hours.