Summary

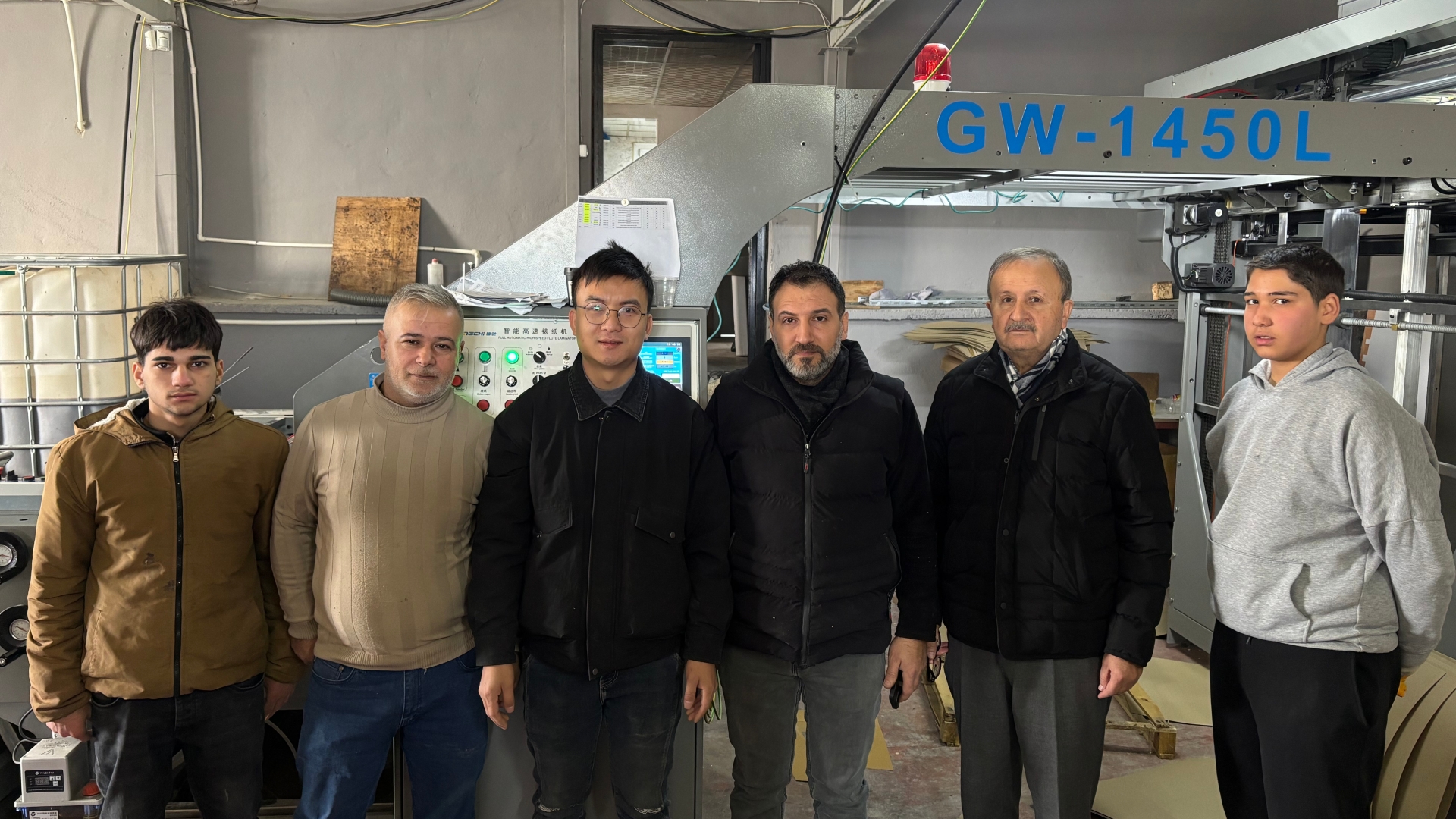

In the final week of November 2025 Fengchi’s after-sales engineers installed an FZ-1450L fully servo-driven automatic flip flop stacker for a customer in Mexico who already ran a GW-1450L fully servo high-speed flute laminator. With the laminator producing up to 22,000 sheets per hour, manual sheet collection became a bottleneck. The FZ-1450L resolved that bottleneck, reduced labor costs, and—together with the laminator—now forms a complete, high-efficiency corrugated laminating production line.

Why the customer needed an automatic stacker

As throughput rose and delivery deadlines tightened, manual collection could no longer keep pace. Key problems were:

- Human collection couldn’t match the laminator’s 22,000 sheets/hour peak output.

- Increased risk of mis-stacks, jams and product damage.

- Rising labor cost and variability in output consistency.

Why the FZ-1450L flip flop stacker was the right solution

The FZ-1450L is a fully servo-driven turner/stacker designed to match high-speed laminators. Benefits delivered to the customer:

- Synchronous operation with the GW-1450L flute laminator for continuous flow.

- Reliable high-speed stacking that eliminates manual bottlenecks.

- Lower labor costs and improved safety.

- Consistent stack quality—reducing rework and shipping issues.

Outcome: a complete corrugated laminating production line

After installation and on-site training by Fengchi’s service team, the customer now operates a fully integrated production line that:

- Increases effective output (removes manual collection delays).

- Enhances on-time delivery capability.

- Improves competitiveness in local and export markets through higher reliability and reduced per-sheet costs.

Installation, training and after-sales support

Fengchi emphasizes that equipment performance depends on correct installation and operator training. For this project Fengchi provided:

- Turnkey installation by after-sales engineers.

- Operator training to ensure safe, efficient use.

- Ongoing service and spare-parts support to maximise uptime.

“Successful installation, training and support are critical to your operations and profitability goals.” — Fengchi Printing Machinery

Is your operation facing a similar bottleneck?

Does your corrugated laminating or printing line struggle with manual handling, inconsistent stacking, or an inability to keep up with your high-speed machinery? The solution exists.

If you have similar needs to boost your production line’s output and efficiency, contact our experts immediately. We will provide a free, customized analysis of your workflow and a detailed quote for a tailored solution that drives your profitability.

Unlock your production line’s full potential. Reach out to Fengchi today for your free consultation and quote.

During late Nov 2025 Fengchi installed an FZ-1450L flip flop stacker to match a GW-1450L high-speed flute laminator (up to 22,000 sheets/hr), eliminating manual collection and cutting labor costs.