High-Speed Flute Laminator

Corrugated laminating solutions for maximum efficiency and precision.

Up to 22,000 sheets/hour, Full-servo control, ±1.0 mm precision, and fast job changeovers.

High-speed Flute Laminator

Engineered for maximum productivity with 22,000 sheets/hour capacity.

Engineered for High Performance

Fengchi specializes in developing, manufacturing, and marketing fully servo high-speed flute laminators for printing and packaging manufacturers. Our machine is very user-friendly – from an operator’s point of view, it’s easy to run and maintain.

High-Speed Operation

Max speed of 22,000 sheets/hour with stable 16,000 sheets/hour for 24/7 operation.

One-Key Operation

Simplified control with intelligent digital interface for rapid job changeover.

Full Servo Control

Full-servo motion control for precise alignment and consistent lamination quality

Energy Efficient

Power consumption about 8 kWh, saving approximately 20% on energy costs.

Explore Our Products

Choose from our two premium series of high-speed flute laminator machines, each designed for specific production needs.

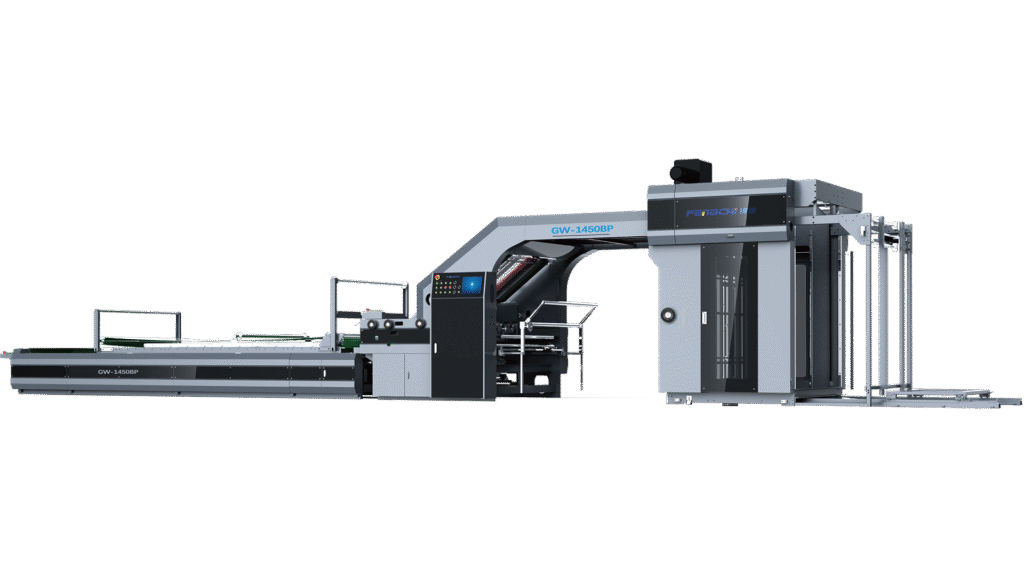

GW BP Series

High-Speed Flute Laminator

GW-1450BP/GW-1700BP/GW-2200BP is the upgraded, fully servo flute laminator engineered for unmatched speed, accuracy, and efficiency. Engineered for 24/7 operation, it’s built to deliver consistent performance while reducing power, labor, and material costs.

Belt Feeder Version

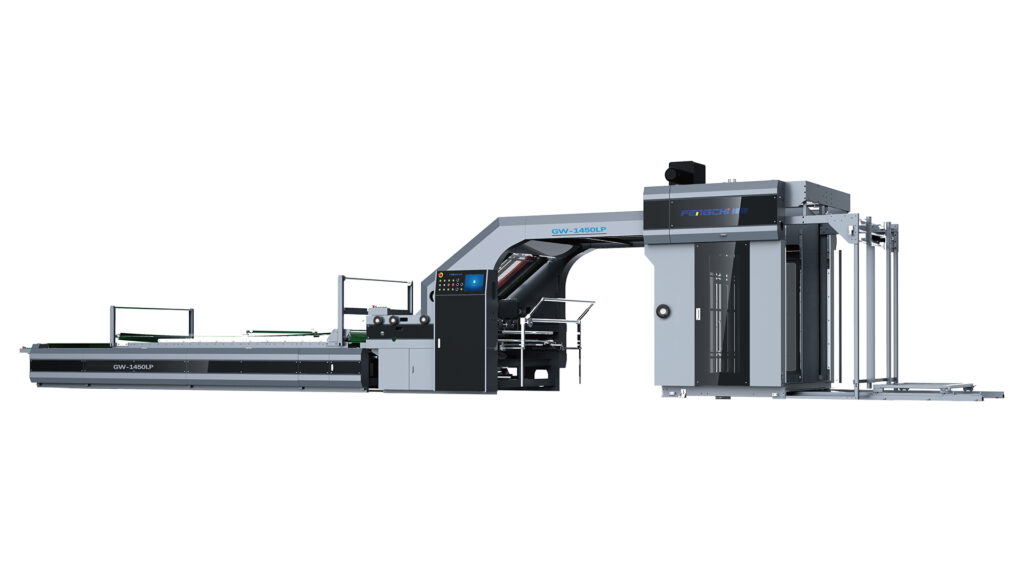

GW LP Series

High-Speed Flute Laminator

GW-1450LP/GW-1700LP/GW-2200LP is the upgraded, fully servo flute laminator delivers unmatched speed, accuracy, and efficiency for laminating corrugated to corrugated and cardboard to cardboard substrates.

Leading Edge Feeder Version

Case Study

How an Intelligent High-Speed Flute Laminator Transformed POS Packaging Production

MicroPack Americas — a 50-year packaging company based in Argentina, the leader in the production of POS Displays in corrugated cardboard — bought Fengchi’s intelligent high-speed flute laminator and saw faster production, more consistent quality, and lower operating costs.

See Our Machine in Action

Real Results from High Speed Flute Laminator Production Line

Supports installation, training & spare parts. Global shipping available.

End-Use Applications

Why Partner with Fengchi?

World Leader

Our track record accumulated over 15 years has allowed us to have top market share globally, and our products receive high customer praise.

High Quality

Fengchi products are manufactured by a team of skilled and qualified technicians. Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Innovative Solutions

We work with you to find not just one, but the right solution for your packaging production – from stand-alone to turnkey.

Global Support

With three offices around the world, and around 50 agents, we are able to provide local support on a global level.

What Our Customers Say

Hear from industry leaders who have transformed their production with our automatic flute laminators.

Julio Miamau

CEO

Farhan Mathur

Operations Director

Haluk Önder

Operator

Trusted by Industry Leaders Worldwide

Major Suppliers

Our Technical Service

After Sales service begins with the arrival of the machinery at the customer’s factory.

To maximize investment whether a single machine or an entire line, the equipment needs to enter the existing production quickly and deliver its contribution. Fengchi offers a dedicated team of technicians that assemble, calibrate and commission the machinery.

Our engineers teach customer operators the machines function, calibration, available options, best practice and scheduled housekeeping.

Fengchi is always available to its customers if they have a problem, concern or malfunctionwith their machinery.

Frequently Asked Questions

Why choose us to cooperate?

1. “FENGCHI” is well-known brand and paper flute laminator master in China since 2009, focus on solving the manufacturing process of over-gluing and laminating & stacking after the post-printing of color cardboard & corrugated cartons.

2. Strong R&D team by 25 senior engineers over 30 years experience in printing industry. With 30 patents to ensure product more stable, more efficient and durable.

3. After-sale service and technical assistance: company provides after sales service and technical assistance as per customers’ requirement and needs with response within 24 hours.

4.Cost saving: Full servo digital operating system greatly reduce operator level(normally two primary operator) with manpower saving, 150mm roller with double bearing and auto refueling system make equipment durable and free maintenance. China highest laminating speed at 22,000pcs/hour.

Are you a manufacturer?

Yes, we are Flute Laminator Master from China over 15 years, specialize in automatic flute laminators and flip flop stackers.

Do you have stock products to sell?

We produce machines in bacth normally. So most models we have some in stock, please check with us before ordering.

How about warranty?

Warranty period: 12 months from the shipping date of machine. Warranty will be not valid if machine subject to misuse or accidental damage or operator’s error. During the valid time, we will supply spare parts. If you have any other questions, pls contact us and we will reply you through product’s photos and videos to make every detail clear. We also provide all lifetime warranty with paid service.

How about installation and training?

Normally, one operator can finish intallation in 2 hours with installation manual and video. If purchaser’s engineer travels at own cost to China, free training session. If engineer sent to purchaser’s factory, all travel cost paid by purchaser.

Do you test all your goods before delivery?

Yes, we have 100% functional testing and pilot run before delivery to ensure product integrity. All products are certificed by CE.

What is your delivery time?

Our delivery time is 10-30 working days after receiving full payment or deposit. The specific delivery time depends on the product and the order quantity.

What are your packaging conditions?

Usually, we pack the machine in a container with a plastic bag with desiccants, then with strong seaworthy wooden cases. Each machine will be protected by anti-rusted oil before put into case.

Will you supply for OEM orders?

Yes, we can customize the production machine according to your requirements.

Request a Quote

Discuss your needs with our experts to obtain customized solutions.