Summary

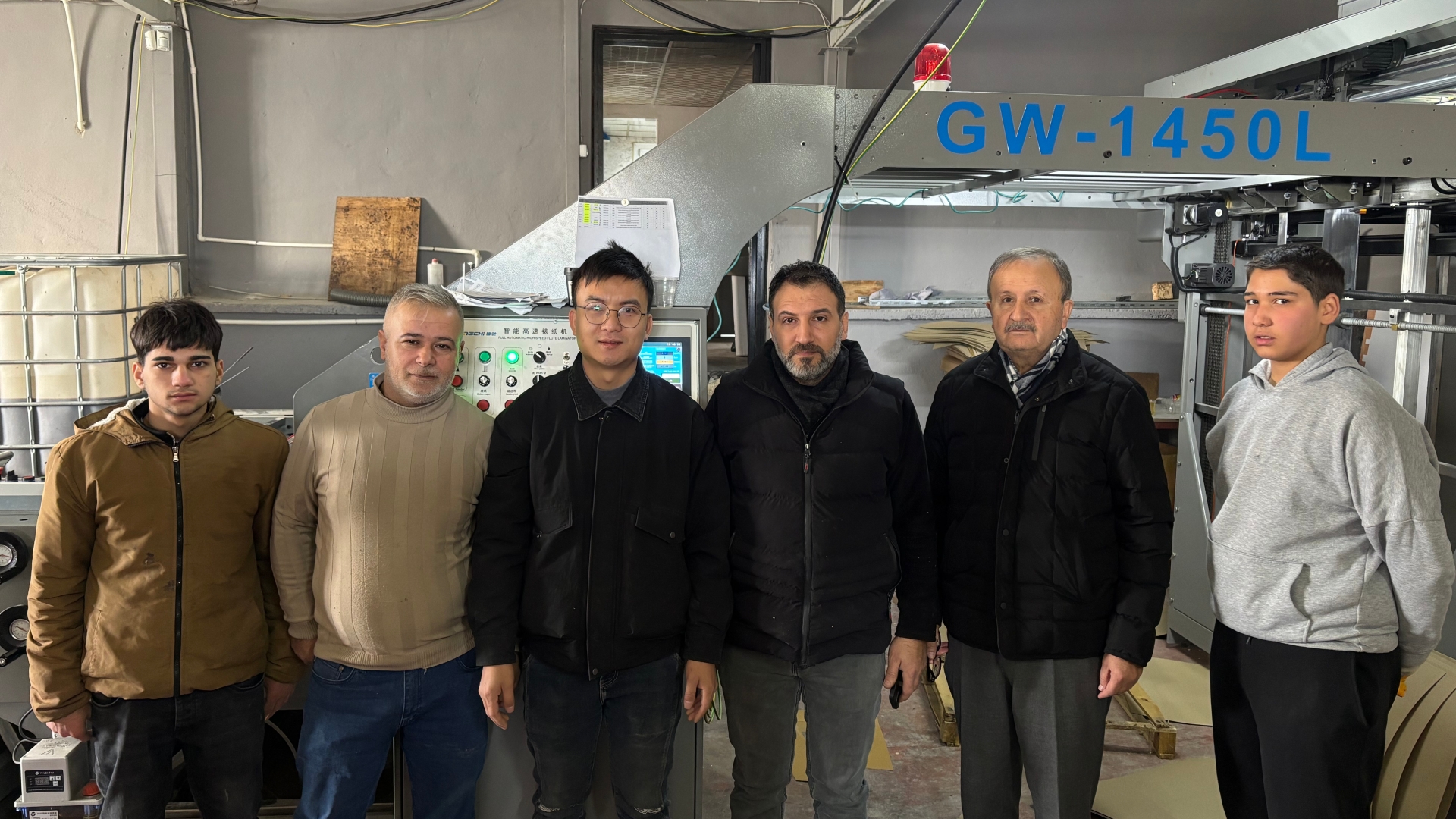

As 2025 draws to a close, Fengchi dispatched experienced after-sales engineers to Brazil to install and commission a GW-1450LP litho laminating production line. The line — a high-speed litho laminator with turner — provides precise adhesive control, stable lamination, high accuracy and high efficiency. The customer’s facility is now in full production; operators received training to ensure long-term stable performance and a fast return on investment.

What was delivered

- Equipment: GW-1450LP litho laminator + full servo flip flop stacker.

- Key technical highlights: precise adhesive control, stable lamination process, high dimensional accuracy, high throughput.

- Outcome: Successful installation and commissioning; machine operating normally in full production.

- Post-installation support: On-site operator training to secure consistent performance and production uptime.

Why litho-laminated sheets matter

Litho-laminated sheets combine the high-resolution appearance of litho-printed sheets with the structural strength of corrugated board. That combination is particularly well suited for packaging categories where appearance and protection both matter:

- Food & beverage packaging

- Household goods

- Electricals & appliances

- Confectionery

- Toys

- Other premium consumer goods

The GW-1450LP is designed to reliably produce these high-quality litho-laminated sheets at scale, while maintaining process consistency and minimizing waste.

Business benefits realized by the Brazilian customer

- Improved product quality: High-resolution print preservation and firm lamination reduce rejects and rework.

- Higher throughput: High-speed configuration raises output while sustaining adhesion quality.

- Lower operating risk: Precise adhesive control reduces variability and consumables waste.

- Faster ROI: Commissioning, operator training and after-sales support accelerate ramp-up to profitable production.

- Longer equipment life & uptime: Proper commissioning and training reduce breakdowns and improve MTBF.

Installation & training — what Fengchi provided

Fengchi’s after-sales engineers completed a full scope of delivery on-site: mechanical installation, electrical integration, system commissioning, process tuning, and hands-on operator training. This end-to-end approach ensures the customer receives not only equipment, but also the know-how required for sustained production stability.

Why choose Fengchi for corrugated laminating solutions

- Industry experience: Track record of international installations and local support.

- Technical expertise: Equipment with advanced adhesive control and process stability.

- End-to-end service: From consultation and model selection to commissioning and long-term after-sales.

- Partnership approach: Focus on building long-term relationships that help customers meet present and future goals.

Talk with our experts about your project

If your business requires reliable corrugated laminating solutions or guidance selecting the right model or customization, contact Fengchi Printing Machinery to discuss specifications, process needs, and deployment schedules.

As we welcome the New Year 2026, the entire team at Fengchi extends our warmest wishes to our global family of clients and partners. May your businesses thrive and prosper. To our dedicated employees around the world, we thank you for your diligence and wish you good health, happiness, and continued success in the coming year.

In December 2025, Fengchi successfully installed a high-speed GW-1450LP litho laminating line for a Brazilian client. Discover how this solution delivers precision & efficiency for premium corrugated packaging.