When evaluating flute laminators, corrugated and folding carton manufacturers should look beyond headline specs to ensure the machine you choose truly meets your production, quality, and budgetary goals. Below are the key considerations to guide your decision:

Production Throughput & Speed

- Yield Consistency – Look for servo-driven control to maintain consistent nip pressure and avoid waste.

- Maximum Speed – Match the flute laminator’s top speed to your automatic folder-gluer or folder-gluer-stitcher.

- Speed Adjustability: Variable speed settings to accommodate diverse order requirements.

- Quick changeovers – systems minimize downtime when switching order.

Flute Profile & Material Compatibility

- Flute Types – Ensure compatibility with the flute sizes you most commonly run (e.g., A, B, E, F‐flute).

- Substrate Range – Verify the machine handles your full span of paperboard weights (e.g., 150–700 gsm) and liner materials.

Lamination Quality

- Bond Strength – Consistent adhesive application, pressure, and temperature control to prevent delamination.

- Precision – Uniform glue distribution and alignment to avoid warping or bubbles.

Automation & Technology

- Integration: Compatibility with existing production lines (e.g., die-cutters, printers).

- Sensors & Controls: Automated monitoring for defects, glue levels, and alignment.

Energy Efficiency

Lower power consumption and heat management systems to reduce operational costs and environmental impact.

Footprint, Workflow & Ergonomics

- Machine Footprint – Balance production capacity against your available floor space—consider modular designs if space is tight.

- Operator Access – Good flute laminator machine layout and safety guarding allow for fast maintenance without compromising safety.

Maintenance, Uptime & Spare Parts

- Preventive Maintenance Plans – Does the OEM offer scheduled service contracts, on‑site training, or remote support?

- Common Wear Parts – Check lead times and availability for essential parts (e.g., adhesive hoses, doctor blades, bearings).

Total Cost of Ownership (TCO) & ROI

- Capital Cost vs. Lifecycle Cost – Factor in energy consumption, maintenance, spare parts, and consumables over a 5–10 year horizon.

- Payback Period – Estimate savings from reduced scrap, faster setup, and higher throughput to calculate ROI.

Vendor Reputation & After-Sales Support

- Global Service Network – Especially important if you operate in multiple regions (Europe, North America, Australia, Africa, Middle East, SE Asia, etc.).

- Training & Documentation – On‑site commissioning, operator training, and clear maintenance manuals ensure smooth hand‑over.

- Customer References – Site visits or case studies help validate real‑world performance claims.

Safety & Regulatory Compliance

CE/UL/CSA Certification – Emergency stops, guards, and compliance with local electrical, machine, and operator‑safety standards.

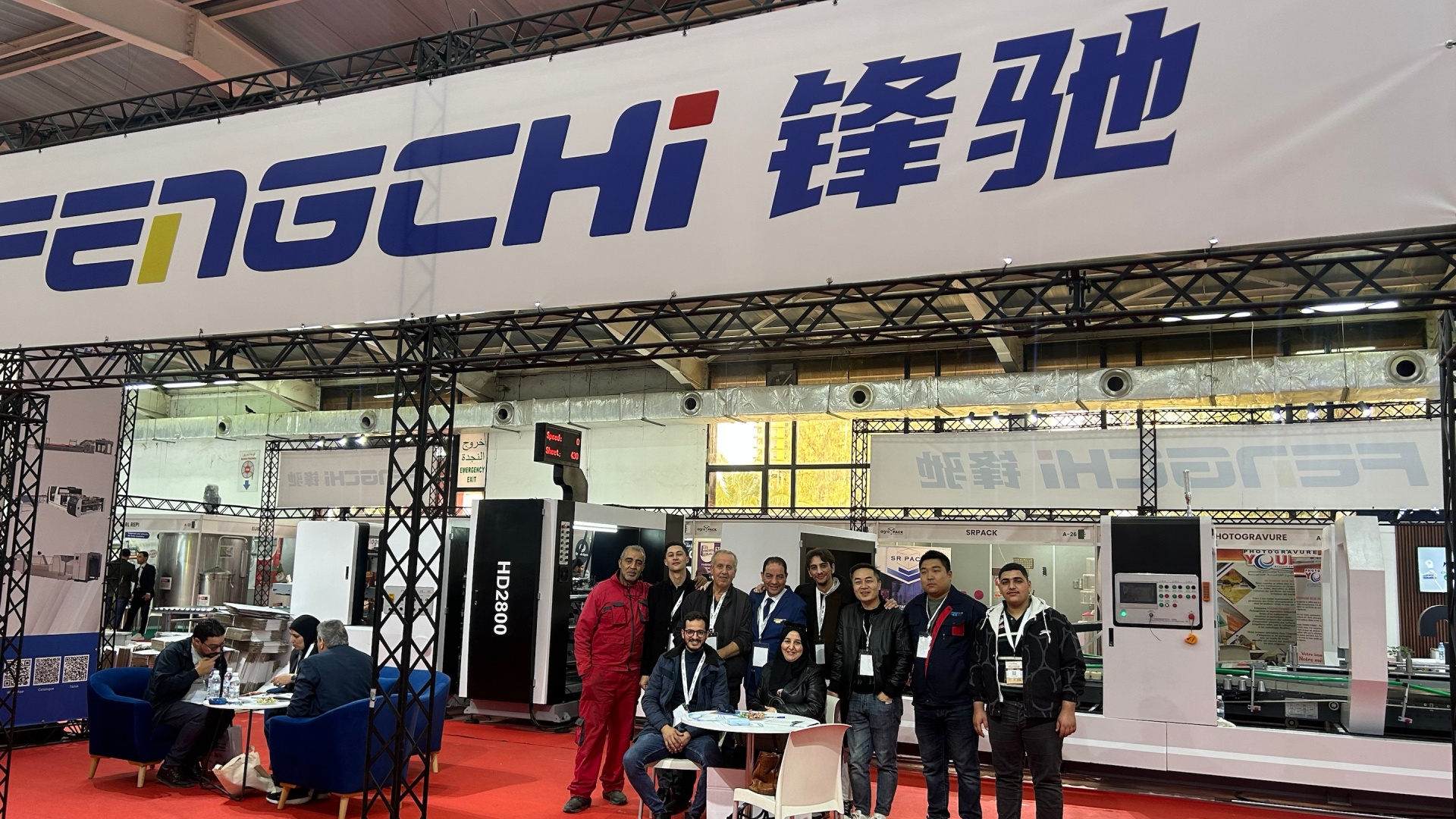

About Fengchi

Our professional flute laminators, equipped with stackers and featuring ten industry-first innovations, enhance factory capacity by 1.5 times compared to competitors. Notably, Fengchi is the sole manufacturer to self-develop software with a $600,000 investment, enabling real remote control and zero breakdowns.

Contact our experts to discuss how to improve your business operations!

When evaluating flute laminators, corrugated and folding carton manufacturers should look beyond headline specs to ensure the machine you choose truly meets your production, quality, and budgetary goals. Below are the key considerations to guide your decision: