Litho laminating machines are specialized systems that bond high-quality printed sheets to substrates (like corrugated board or paperboard) using adhesive and pressure. This process is essential in industries like packaging and print finishing because it combines vivid graphics with durable materials. By automating lamination, these machines dramatically boost throughput and consistency.

The lithographic print allows for high-resolution graphics, sharp text, and vibrant colors, making the packaging stand out on store shelves. The corrugated layer provides the necessary strength and durability to protect products during shipping and handling.

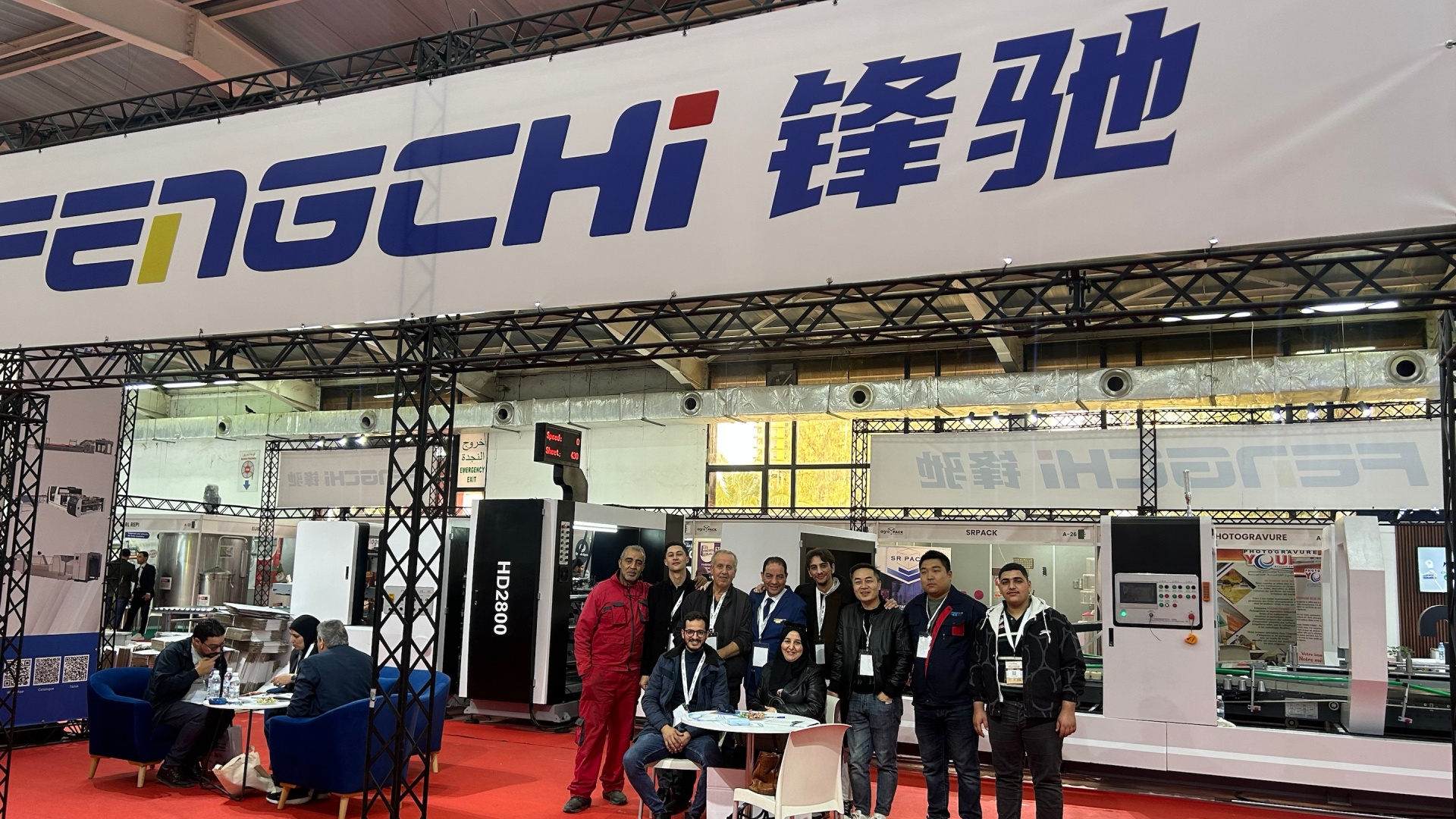

Fengchi’s litho laminating lines integrate sensors, conveyors, and controls to run with minimal human intervention. Advanced systems use servo-driven feeders and vacuum belts to position boards precisely, while PLC touchscreens display real-time status (speed, errors, etc.) so operators can make instant adjustments.

litho laminating lines video demo

Key features include

- Servo-Driven Feeders: High-speed, vacuum-assisted feeders precisely align and feed top and bottom sheets, enabling accurate, hands-off operation.

- Touchscreen Controls & Monitoring: PLC interfaces and sensors display running speed, glue flow, and error alerts on-screen, so issues can be corrected instantly.

- Automated Setup: Pre-pile systems use touch-panel presets to pre-align sheets before they enter the laminator, slashing changeover time and waste.

- Interconnected Technology: The seamless integration of a high-speed flute laminator and full servo flip flop stacker eradicats process barriers and propelling automation to unprecedented levels.

Benefits of lithographic lamination machine

- Production Speed and Throughput: Modern litho laminators deliver very high output rates. They can laminate thousands of sheets per hour, far exceeding manual methods. For example, Fengchi’s high-speed flute laminating machines routinely operate at up to 175 m/min (roughly 22,000+ sheets per hour).

- Product Quality Enhancement: Litho laminating machines enhance the quality and consistency of the finished product. They apply adhesive with precision rollers and even pressure, so each area of the printed sheet is bonded uniformly.

Industry applications of litho laminator

Litho laminators are most common in packaging and print finishing industries, where high-quality laminated boards are required at scale.

Corrugated box and folding carton manufacturers use litho laminators to adhere pre-printed liners onto board. This creates boxes that are both visually striking and structurally strong.

End-use categories

Contact Our Experts Today

Are you ready to take corrugated board production to the next level with litho laminating machines? Contact us to learn how flute laminators can benefit your business and how we can help.

Litho laminating machines are specialized systems that bond high-quality printed sheets to substrates (like corrugated board or paperboard) using adhesive and pressure. This process is essential in industries like packaging and print finishing because it combines vivid graphics with durable materials. By automating lamination, these machines dramatically boost throughput and consistency.