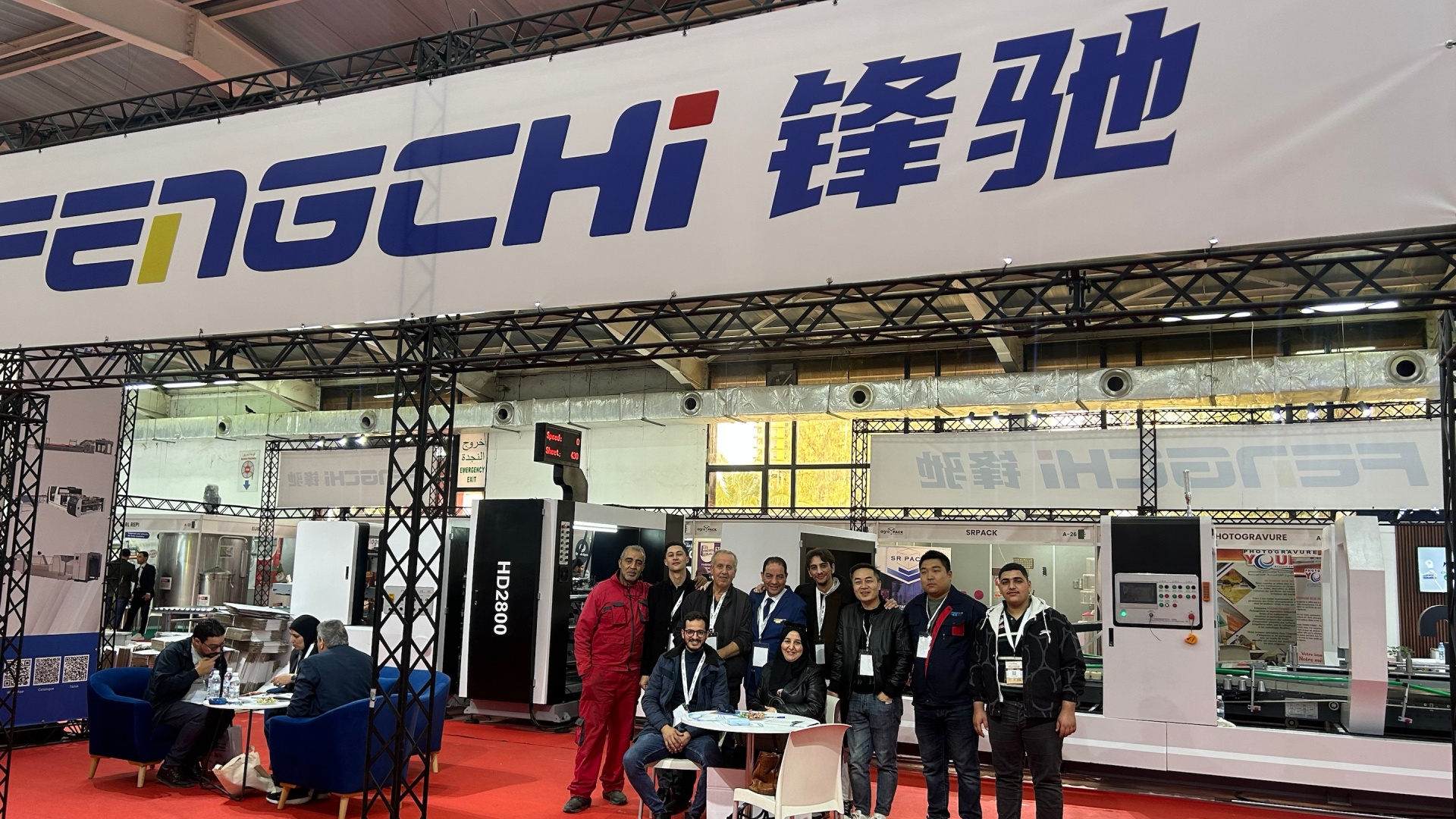

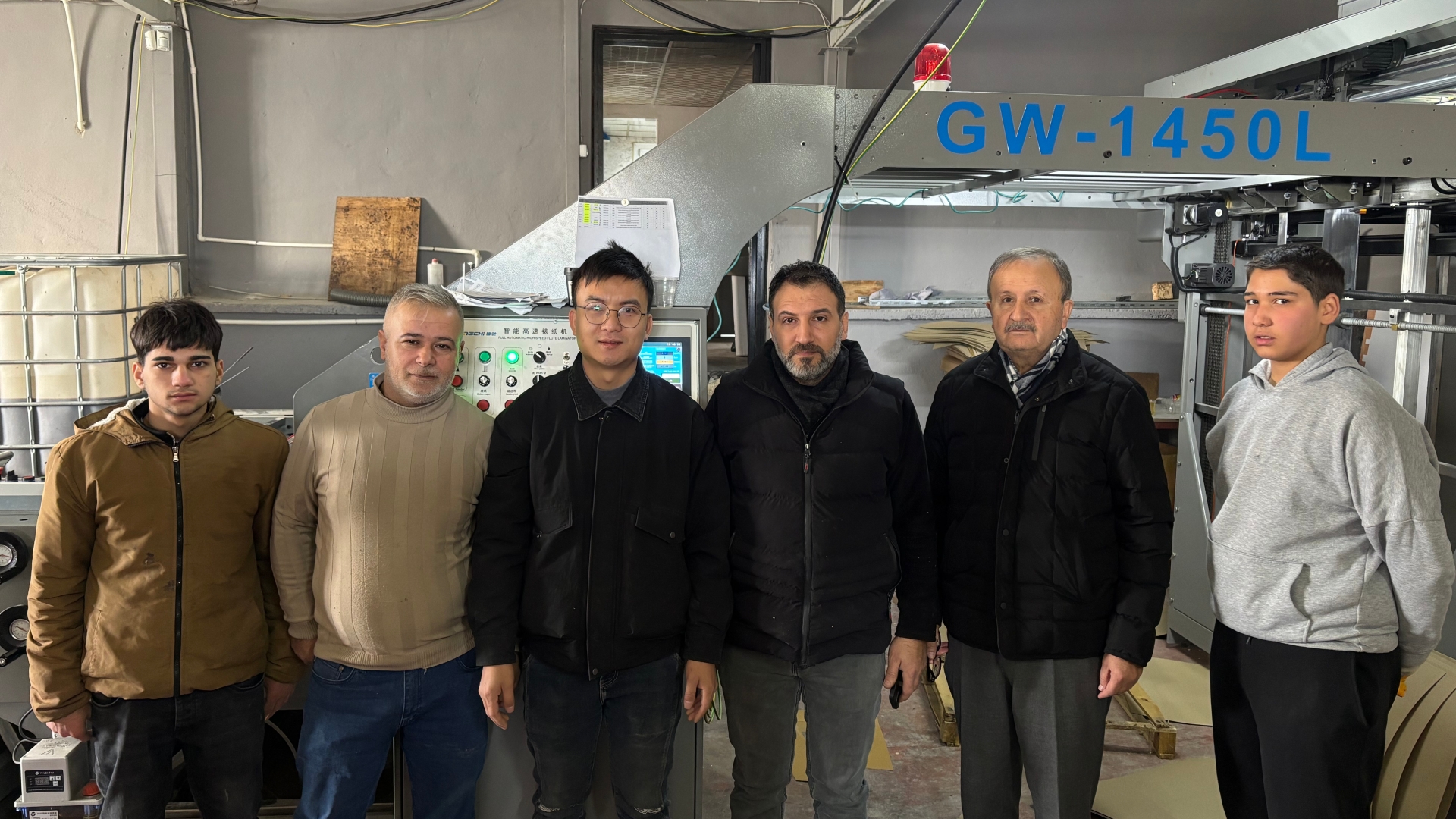

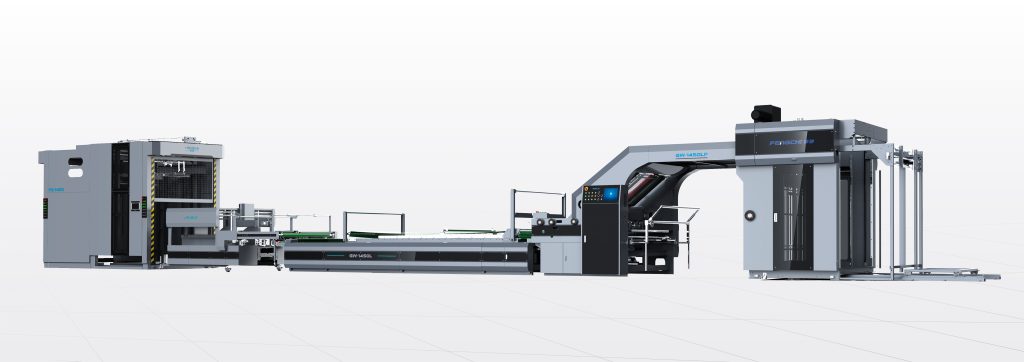

This week, Fengchi Printing Machinery successfully installed a state-of-the-art litho laminating line for a leading packaging customer in Algeria. The production line consists of a GW-1450LP fully servo high-speed flute laminating machine and an FZ-1450 flip flop stacker, helping them corrugated packaging efficiency and overall productivity.

Why Choose a Litho Laminating Line for Corrugated Packaging?

- High-Speed Production: Modern litho laminating machines can run at speeds exceeding 200 meters per minute, ensuring large-volume output without sacrificing quality.

- Superior Bond Strength: Advanced adhesive systems create durable, uniform bonds between printed linerboard and corrugated sheets, reducing delamination risk.

- Enhanced Print Quality: Precision alignment and tension control maintain perfect register, delivering crisp graphics and vibrant colors on every sheet.

- Reduced Waste: Minimize downtime with our preventive and corrective maintenance services translate to higher yields.

Our Proven Process: From Advice to Maintenance

Expert Advice & Equipment Selection

Our team of seasoned packaging engineers conducts a thorough site evaluation to recommend the optimal litho laminating line tailored to your production goals. Whether you need high-speed flute laminators or flip-top stacking machines, we’ll guide you toward the best solution for:

- Throughput requirements

- Substrate types(printed cardborad, corrugated sheet, etc.)

- Budget considerations

Professional Installation & Operator Training

After delivery, our certified technicians handle mechanical and electrical installation, followed by comprehensive operator training:

- Operation: Step-by-step guidance on startup, changeovers, and quality checks.

- Maintenance: Hands-on instruction in routine checks, lubrication, and part replacement.

- Safety: Full coverage of lock-out/tag-out procedures and emergency protocols.

This ensures your team is fully equipped to run the line at peak performance from day one.

Preventive & Corrective Maintenance

To keep your corrugated laminating line running smoothly, we offer:

- Preventive Maintenance Plans: Scheduled inspections, consumable replacements, and calibration to avoid unplanned downtime.

- Corrective Services: Rapid response for troubleshooting, spare-parts delivery, and on-site repairs.

- 24/7 Technical Support: Remote diagnostics and expert guidance any time you need it.

Why Fengchi Printing Machinery?

Fengchi Printing Machinery is a global leader in high-speed flute laminators and flip-top stackers, with a strong domestic foundation and growing international presence. We are committed to:

- Continuous R&D: Innovating adhesive systems, Independently developed operating system, and automation features.

- Exceptional Quality: Rigorous factory testing ensures reliability and longevity.

- Customer Success: Tailored service packages that maximize ROI and throughput.

Success Story: Algeria Installation Outcomes

- Production Increase: 80% boost in daily output thanks to reduced changeover times.

- Quality Improvement: 25% fewer packaging defects, leading to lower waste.

- Operator Confidence: Fully trained staff capable of independent line management.

Ready to Optimize Your Packaging Line?

Contact Fengchi Printing Machinery today for a free technical consultation, detailed quote, and machine demonstration. Let our experts help you design, install, and maintain the perfect laminating solution for your corrugated packaging needs.

- WhatsApp: +86-13316603290

- Email: sales@laminatorfc.com

Discover how Fengchi’s high-speed litho laminating line installation in Algeria enhanced corrugated packaging efficiency. Contact us for more information and to receive a free consultation, brochure, and demonstration.