Model Q Window Patcher

Automatic window patching solution for folding carton packaging,

combining intelligent control with exceptional reliability for flawless results.

Model Q Window Patcher

Automatic window patching solution for folding carton packaging

Key Features & Benefits

Model Q Window Patcher is designed to provide you with the most reliable and efficient packaging solutions.

High Productivity

Max speed 9,000 sheets/hr (155m/min), continuous 8,000 sheets/hr (138m/min), 24h non-stop.

Precision Control

±0.5 mm film accuracy. (full‑servo bus + proprietary tech)

Intelligent Collection

Auto count & stack collection for non‑box products.

Long-Term Durability

35% load‑reserve servos; > 15 year life span.

Fast Setup & Changeover

Digital feed, glue‑position & film‑length settings.

Synergistic Drive System

6 servos + 3 motors; one‑touch smart operation.

Technical Specifications

Choose from three models designed to handle a wide range of packaging requirements with precision and efficiency.

| Parameter / Model | BTM-760Q | BTM-950Q | BTM-1100Q |

|---|---|---|---|

| Paper size (W x L) | 760 x 780 mm - 150 x 130 mm | 950 x 780 mm - 150 x 130 mm | 1100 x 780 mm - 150 x 150 mm |

| Window dimension (W x L) | 380 x 300 mm - 50 x 50 mm | 380 x 300 mm - 50 x 50 mm | 480 x 350 mm - 50 x 50 mm |

| Paper weight / sheet thickness | Cardboard: 200~2000 g/㎡ Corrugated board: 1-3 mm | ||

| Film thickness | 0.1-0.3 mm | ||

| Positioning accuracy | ±0.5 mm | ||

| Mechanical speed | Up to 8000 sheet/hour | ||

| Power voltage | 380V/50Hz (Three-phase) | ||

| Machine power | 16 kW | ||

| Machine weight | 3000 KG | 3200 KG | 4000 KG |

| Overall dimension (L x W x H) | 7500 x 1600 x 2000 mm | 7500 x 1750 x 2000 mm | 7500 x 1950 x 2000 mm |

* Need a tailored specification? Contact our sales engineers for custom configuration based on your site requirements.

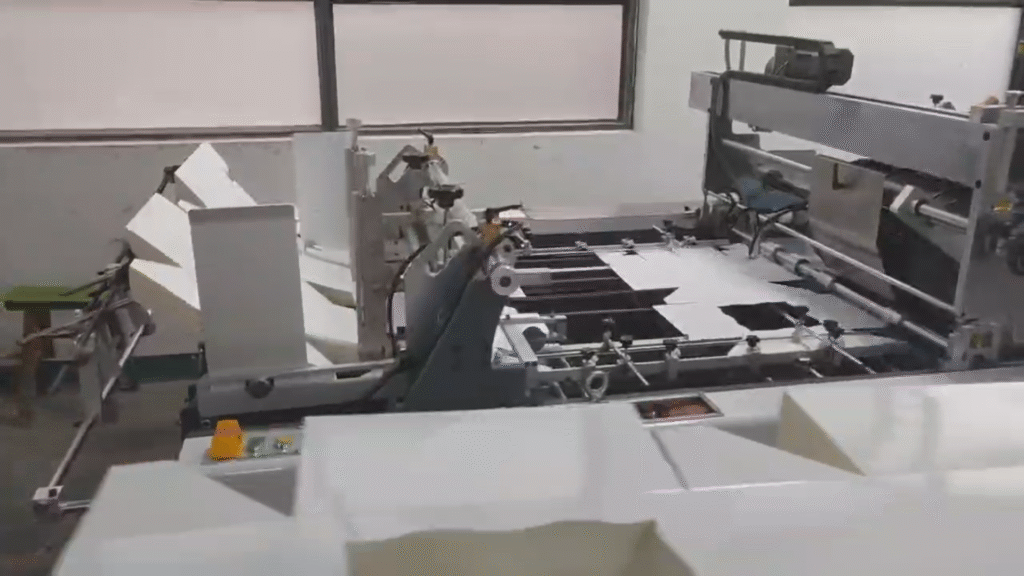

See It in Action

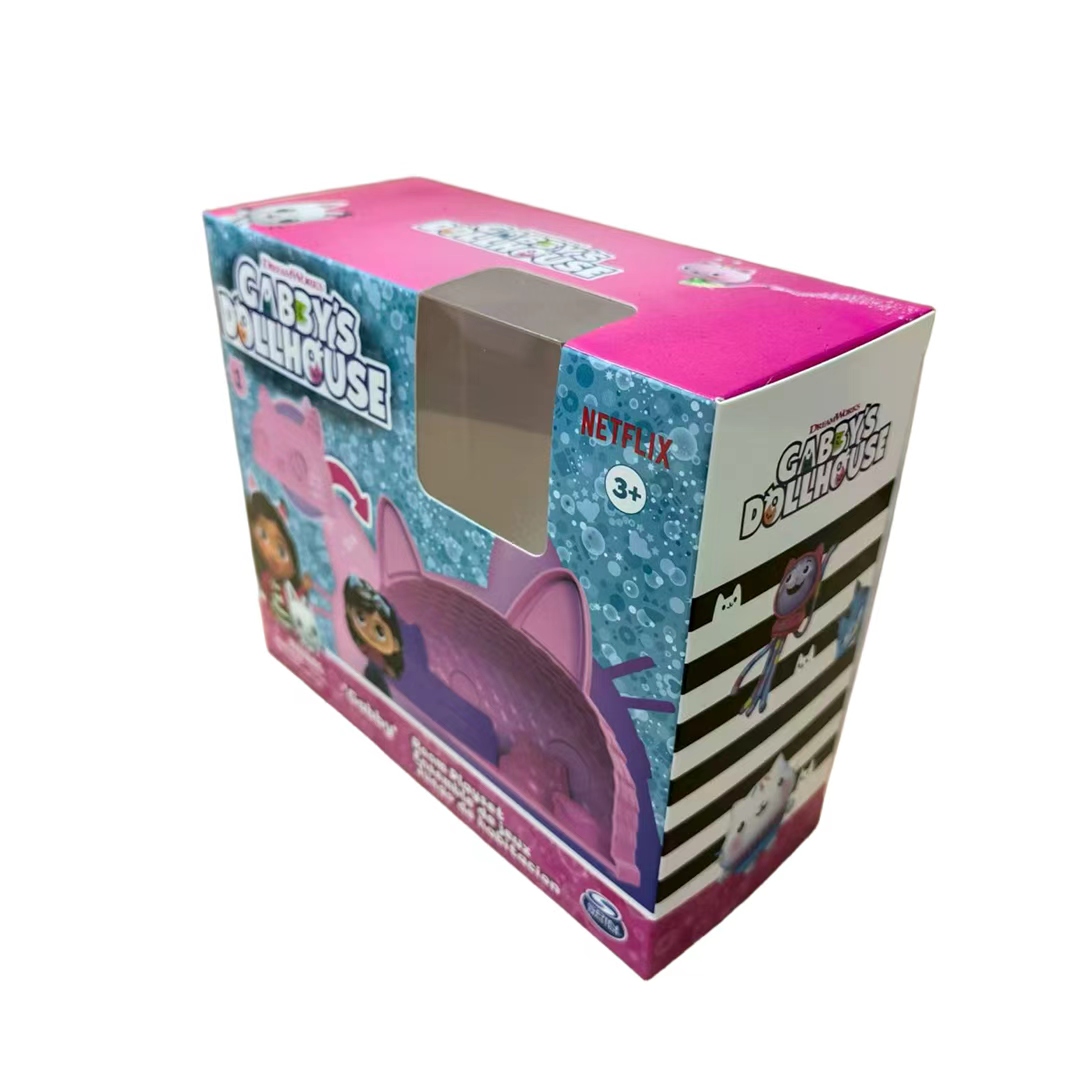

Designed for Diverse Packaging Applications

The Model Q upgrades manual or semi-automatic processes to a reliable, servo-controlled window patching solution suitable for various industries.

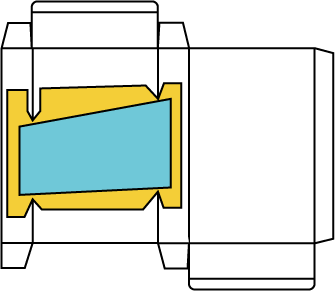

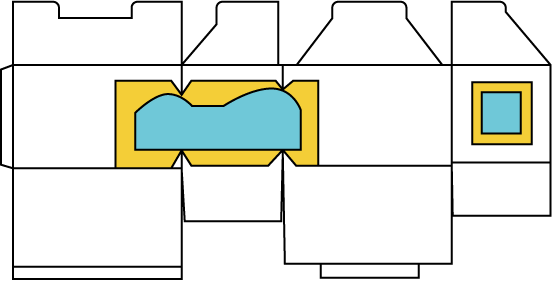

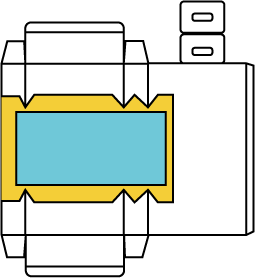

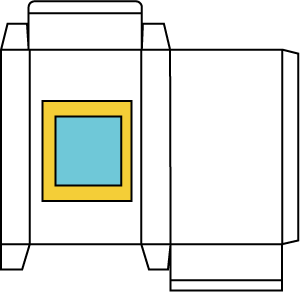

Window Styles

Product Highlights

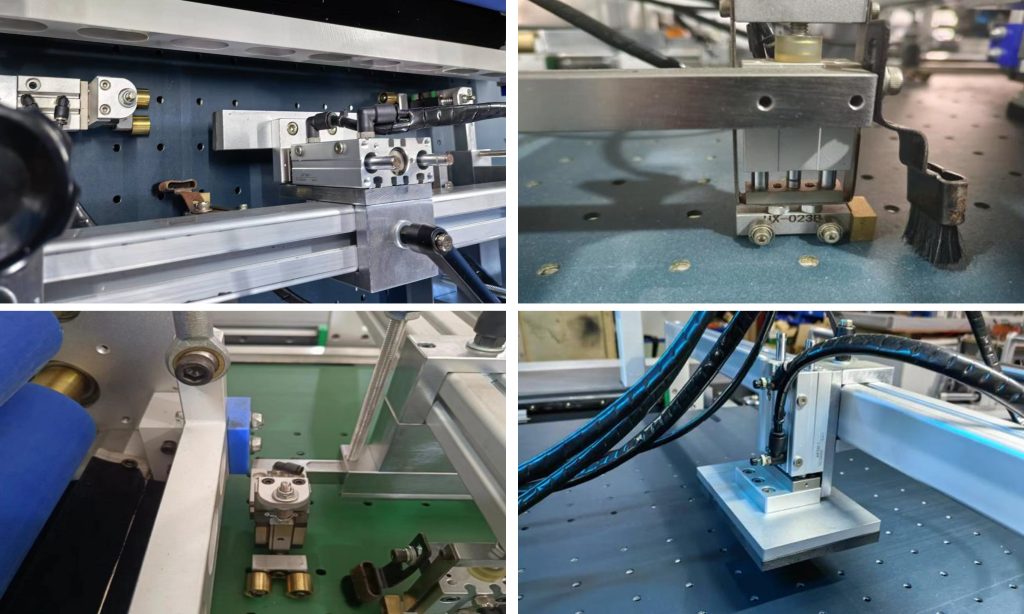

Paper Pressing Wheel Assembly

- Gear-driven dual-power transmission on upper/lower wheels delivers exceptional stability during paper conveyance, particularly with corrugated paper.

Glue Distribution System

- Dedicated servo drive simplifies transmission and maintenance.

- Entire unit slides out for cleaning.

Box Collection Unit

- Fish-scale collection structure with weighted rollers enhances film-box adhesion.

Highlights Paper Feeding System

- Features optimally stable separation blades with zero wobble when locked, ensuring superior paper separation.

- Single-plate feeding belt simplifies maintenance and replacement. Linear bearings enable smooth front/rear movement of the paper pressing mechanism; pneumatic vibration motors reduce noise and optimize vibration.

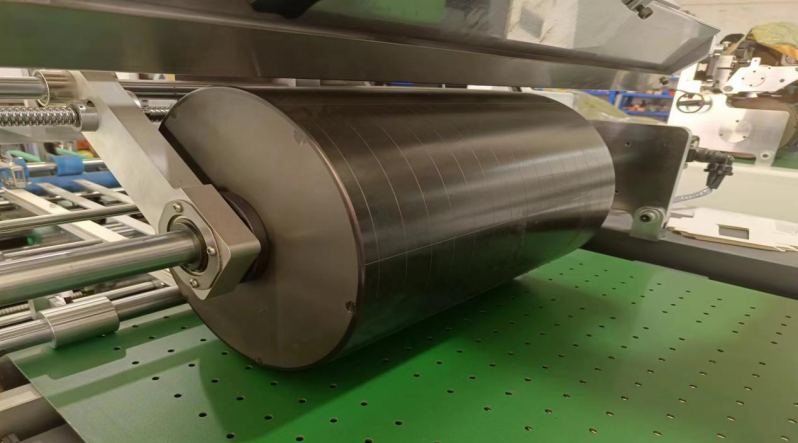

Gluing System

- Independent servo drive allows parameter input via HMI without wrenches or phase adjustment.

- Hard-anodized aluminum alloy glue rollers offer lightweight and high hardness.

- Optimized program with glue sensor enables automatic activation with product presence, separation without product, and jam alarm/shutdown.

Pusher Claw System

- Linear guide fixation eliminates vibration (vs. linear bearings), ensuring stable paper feed.

- Patent-certified synchronous belt drive provides quiet operation, stretch resistance, oil-free performance, low noise, and sustained precision.

- Front/rear adjustable press wheels adapt to product positions; side-fixed design simplifies setup. Side guides synchronize with claws to reduce adjustment frequency and time.

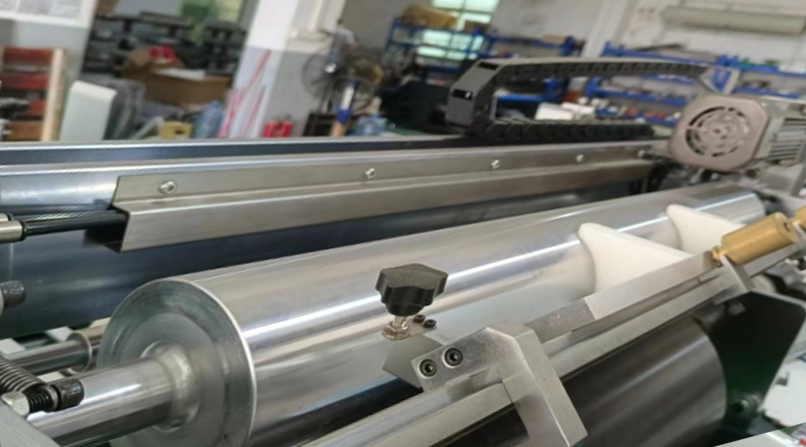

Film Forming Section

Dual-servo drive technology (patent-certified) integrates film

feeding, horizontal creasing, punching, print registration,

vertical creasing, and cutting for precision forming.

- Film Feeding Unit: Dual linear guides prevent swing arm deviation; PLC-controlled motor runs continuously during start/stop; heating optional for films ≥ 0.25 mm.

- Horizontal Creasing: Linear module + stepper motor (smooth high-speed operation, easy maintenance).

- Punching Unit: Cylinder-driven metal mold; front/rear adjustment (linear guides + rack-and-pinion); left/right adjustment (linear guides + ball screws).

- Print Registration: Precise adjustment of printed patterns.

- Vertical Creasing Unit: Vertical adjustment (linear guides + eccentric blocks); horizontal adjustment (guides + ball screws).

- Cutting Unit: Cylinder-powered spring-compressed blades for quick adjustment.

Lamination Section

- Front positioning: Two cylinders + four bearings + positioning block (bearings contact belt, block suspends to protect belt).

- Side positioning: Conventional guides or invention-patented push gauge.

- Pneumatic double-pressing sequence: Boxes positioned → film extended → belt stops → pressed/cut → system reset.

Electrical System

- INOVANCE components (China’s top-tier brand) with bus-based control ensure efficient, stable operation and simplified maintenance.

Why Partner with Fengchi

Our commitment to quality, reliability, and customer success has made us the preferred choice for packaging manufacturers worldwide.

Certified Quality

ISO 9001:2015 certified manufacturing processes with rigorous quality control at every production stage.

Vast Experience

More than 15 years of experience within automation gives us an enormous know-how and expertise in laminating solutions.

30 + Patents

We continuously push the boundaries of speed and performance, securing 30 patents through independent research and development.

Global Support

Agents in over 50 countries with local technical support and emergency service availability.

What Our Customers Say

Hear from packaging professionals who have transformed their production with the Model Q Window Patcher.

"The Model Q has completely changed our approach to quality control. We've reduced our scrap rate by over 90% and our technicians can now focus on more complex tasks. It paid for itself in just 10 months!"

Michael Torres

Production Manager, Premium Packaging Solutions

Trusted by Industry Leaders Worldwide

Our Service for Your Success

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines.

Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

Frequently Asked Questions

What is the maximum speed of the Model Q Window Patcher?

Model Q window patcher machine achieves a maximum speed of 9,000 sheets per hour.

What materials can the Model Q Window Patcher handle?

Compatible with folding carton, paperboard, cardboard, and corrugated packaging.

Can the machine be adjusted for different window sizes?

Yes, the Model Q Window Patcher is highly customizable to accommodate various window dimensions and designs.

What is the typical delivery time?

Usually 10–30 days depending on configuration. Contact us for a precise quote.

Is technical support available for new users?

Absolutely. We provide comprehensive training and ongoing support to ensure you make the most of your investment.

Can we see the machine operating?

Yes — factory demos and video demonstrations are available on request.