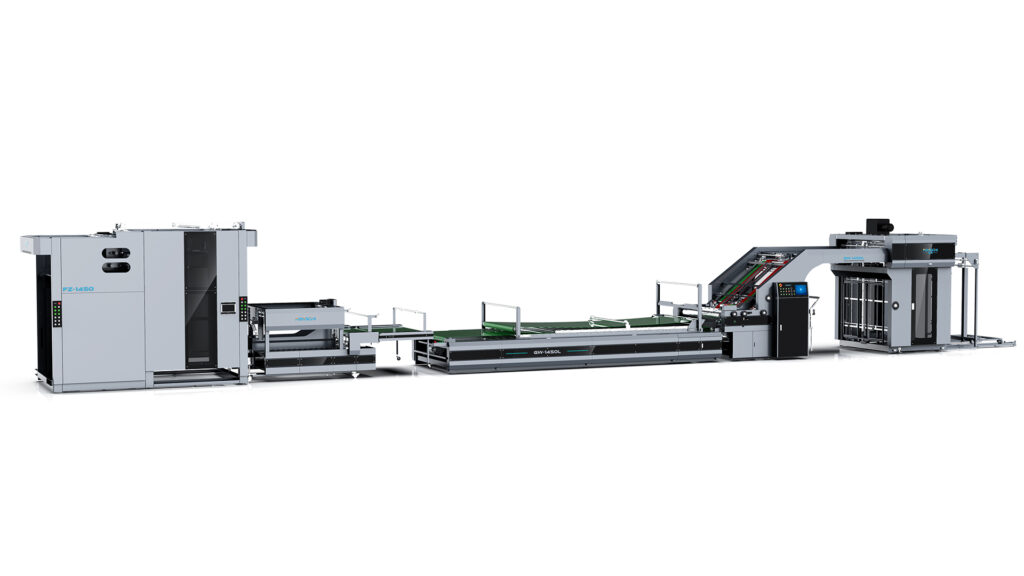

High-Speed Flute Laminator Line

Maximize output & minimize downtime with precision corrugated board lamination

Increase productivity with our reliable flute laminator line.

Key Features & Benefits

High Production Capacity

Maximum speed of 22,000 sheets/hr with continuous operation at 16,000 sheets/hr, 24h non-stop.

Quick Changeover

Adopting 7-8 servo motors control systems, digital intelligent input, automatic order changeover in 2-3 min.

Leading-edge Feed System

Self-developed leading-edge feed system specially for deformed, warped corrugated papers.

Enlarged Glue Roller

Enlarged 150 mm diameter stainless steel roller, laser engraved anilox, high-speed and stable without glue splashing.

Pre-stacking System

Whole pallet loading platform, saving labor costs and time.

Global Support

Worldwide installation, training, and spare parts service.

Our Product Series

Choose from our automatic flute laminator lines, each designed for specific corrugated packaging production requirements.

High-Speed Flute Laminator Line ( Upgraded Version )

GW-1450LP/GW-1450BP/GW-1700LP/GW-1700BP/GW-2200LP/GW-2200BP is engineered for corrugated packaging manufacturers seeking higher output, stable lamination quality, and rapid return on investment.

High-Speed Flute Laminator Line

GW-1450L/GW-1700L/GW-2200L is a high-speed sheet-to-sheet laminator specifically designed for accuracy and efficiency.

Our full servo high speed flute laminator line is engineered for corrugated packaging plants.

Automatic Flute Laminator Line

GE-1450B/GE-1450BP/GM-1450B fully automatic flute laminator, specifically designed for corrugated packaging manufacturers requiring high output without compromising laminating quality. Featuring full servo control, it achieves a maximum capacity of 13,000 sheets per hour with precision of ±1.0 mm.

Key Differences

For example: The 1450 model within the four major series (GE, GW, GW LP and GW BP)

| Item | GE-1450B | GW-1450L | GW-1450LP | GW-1450BP |

|---|---|---|---|---|

| Maximum Speed | 13,000 sheets/hour (153 m/min) |

22,000 sheets/hour (175 m/min) | 22,000 sheets/hour (175 m/min) |

22,000 sheets/hour (175 m/min) |

| Bottom Paper Range | 300 gsm – 10 mm | F flute – 10 mm | F flute – 10 mm | 300 gsm – 10 mm |

| Feeder System | Belt feeder | Leading edge feeder | Leading edge feeder | Belt feeder |

| Market Positioning | Standard | High-speed production | High-speed, premium positioning |

High-speed, premium positioning |

| Design & Structure | Traditional design | Improved performance design | New mechanical layout & modern appearance |

New mechanical layout & modern appearance |

Practical Selection Guidance

- GE-1450B: Ideal for cost-sensitive buyers and medium production volumes.

- GW-1450L: Designed for high-output plants requiring maximum productivity.

- GW-1450LP and GW-1450BP: Best suited for premium markets where technology image and machine aesthetics matter.

End-use Applications

See It In Action

Real Results from GW-1700LP High Speed Flute Laminator Production Line

Case study — Fengchi Installs First GW-1700LP Flute Laminating Line in Australia

Fengchi has completed the successful installation and commissioning of its first litho laminating machine production line in Australia — a milestone that demonstrates how targeted customer service, field testing and high-quality engineering combine to meet demanding production needs. The Australian client chose the GW-1700LP high-speed flute laminator plus a flip-flop stacker, replacing an older competitor machine to gain speed, reliability and automation.

Why Partner with Fengchi?

High Quality

Fengchi products are manufactured by a team of skilled and qualified technicians. Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Innovative Solutions

We work with you to find not just one, but the right solution for your packaging production – from stand-alone to turnkey.

Global Support

With three offices around the world, and around 30 agents, we are able to provide local support on a global level.

What Our Customers Say

Hear from industry leaders who have transformed their production with our automatic flute laminator lines.

I really like FENGCHI’s machines. These machines are easy to operate, and the finished products are very good.

– Haluk Önder, Operator

The technical support is exceptional. When we had a minor issue, their team resolved within 24 hours.

– Maria Johnson, Operations Director

The precision and consistency of the flute laminating line have significantly improved our product quality.

– Robert Williams, CEO

Trusted by Industry Leaders Worldwide

Major Suppliers

Our Technical Service

After Sales service begins with the arrival of the machinery at the customer’s factory.

To maximize investment whether a single machine or an entire line, the equipment needs to enter the existing production quickly and deliver its contribution. Fengchi offers a dedicated team of technicians that assemble, calibrate and commission the machinery.

Our engineers teach customer operators the machines function, calibration, available options, best practice and scheduled housekeeping.

Fengchi is always available to its customers if they have a problem, concern or malfunctionwith their machinery.

Request a quote

Let’s discuss your production needs so we can offer specific solutions.