Flute Laminating Line

Automatic Flute Laminating Line for corrugated packaging

— precise glue control, servo alignment and flip-flop stacker.

Flute Laminating Line

Automatic flute laminating line engineered for corrugated packaging production.

Features & Benefits

Automatic flute laminating lines are Engineered for maximum productivity, precision, and return on investment for corrugated packaging, POS displays, and laminated cardboard products.

High Throughput

Achieve production rates up to 13,000 sheets/hour (153 m/min) to meet tight deadlines and high-volume orders.

High Accuracy

Maintain consistent ±1.0mm laminating precision with advanced servo tracking, eliminating waste and rework.

Minimal Downtime

Switch jobs in just 2-3 minutes with fast changeover systems for flexible batch production.

Easy to Operate

Intuitive controls reduce dependency on highly experienced operators and minimize training time.

Built for Longevity

Engineered with a 35% load reserve for 15+ years of reliable performance and maximum ROI.

Energy Efficient

Kinetic energy recovery system reduces power consumption, making operation more economical.

See Automatic Flute Laminating Line in Action

End-use Packaging Samples

Technical Specifications

| Parameter / Model | GE-1450B | GE-1450BP | GM-1450B |

|---|---|---|---|

| Max. Working Speed | 13,000 sheets/hour | 13,000 sheets/hour | 10,000 sheets/hour |

| Max. Paper Size (W x L) | 1450 x 1450 mm | 1450 x 1450 mm | 1450 x 1450 mm |

| Min. Paper Size (W x L) | 360 x 360 mm | 360 x 360 mm | 360 x 360 mm |

| Laminating Accuracy | ±1.0mm | ±1.0mm | ±1.5mm |

| Bottom Paper Thickness | 300gsm - 10mm | 300gsm - 10mm | 0.3–7 mm |

| Applicable Glue | Resin adhesive, starch glue (PH6-8) | Resin adhesive, starch glue (PH6-8) | PVA, starch adhesives (PH 6-8) |

| Power Supply | 380 VAC/3P | 380 VAC/3P | 380 VAC/3P |

| Power Consumption | 20 kW | 20 kW | 20 kW |

| Applicable Substrates | A, B, C, E, F, 3ply, 5ply corrugated board, and cardboard within above mentioned range | A, B, C, E, F, 3ply, 5ply corrugated board, and cardboard within above mentioned range | A, B, E, F flutes, double-flute and other flat corrugated boards; cardboard ≥ 300 gsm for lamination |

| Machine Weight | 7000 KG | 7000 KG | 6500 KG |

| Overall Dimension (L x W x H) | 15400 x 2300 x 2550 mm | 15400 x 2300 x 2550 mm | 11500 x 2300 x 2550 mm |

* This is the current configuration. It may be updated as technology evolves.

Product Gallery

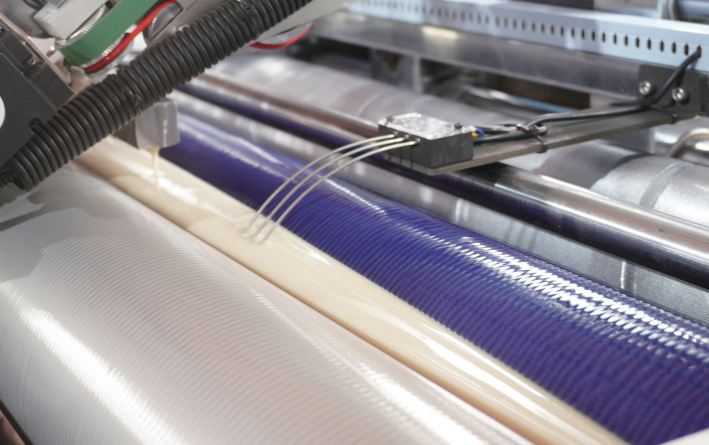

Feeding System for Bottom Paper

- Adopting advanced high speed motion control servo tracking system to ensure laminating accuracy.

Paper Aligning System

- The lifting platform is controlled by 4 sets of double chains to ensure the smooth and safety operation

- 10 limits and protective sensors, real-time detection and adjustment to ensure safety production

- Industry Initiative of servo control lifting platform, single sheet lifting same as offset printing press, without wear, and can be set as from 1~50 sheet/lifting.

Simple Operation Interface

- Full servo automatically adjusts the amount of glue and the height of bottom board, the quality control becomes simpler and easier, and greatly reduces dependence on operator.

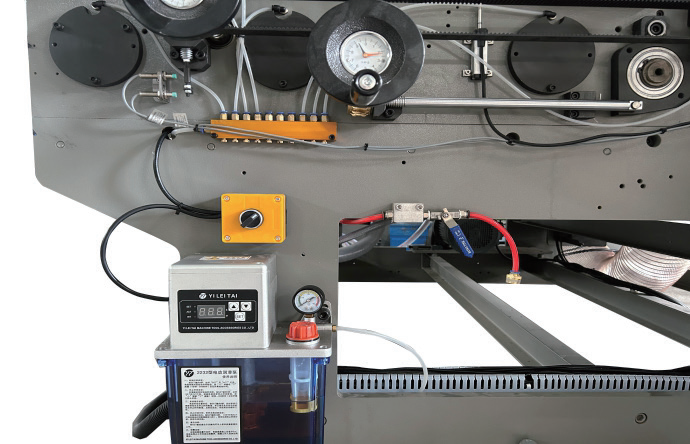

Automatic Lubrication System

- Automatic lubrication system aims for maintenance- free equipment.

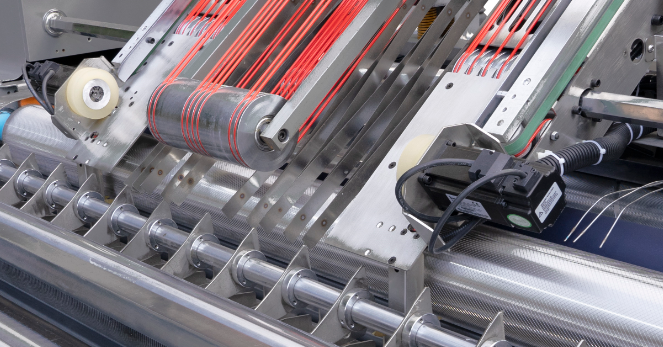

Enlarged Glue Roller

- Enlarged 150mm diameter stainless steel roller, laser engraved anilox, high-speed and stable without glue splashing.

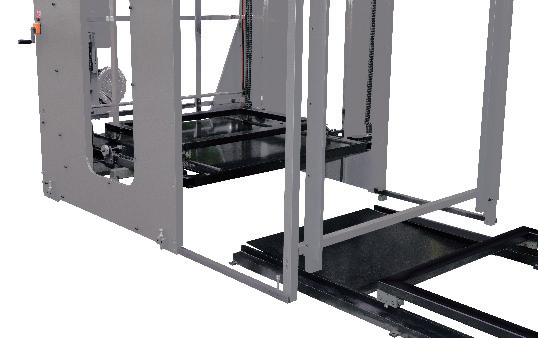

Pre-stacking System

- Whole pallet loading platform, saving labor costs and time.

Why Partner with Fengchi?

High Quality

Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Vast Experience

More than 15 years of experience within automation gives us an enormous know-how and expertise in laminating solutions.

30 + Patents

We continuously push the boundaries of speed and performance, securing 30 patents through independent research and development.

Global Support

We proudly export corrugated laminating solutions worldwide, ensuring international clients benefit from our innovative technology.

Trusted by Industry Leaders

Major Suppliers

First Class Service & Support

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines. Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

Request a Quote

Get a personalized consultation and detailed quote. Our experts will contact you within 24 hours.