Automatic Spot UV Coating Machine

Our automatic spot UV coating machine adds a precise, high-glossy finish to specific parts of your print, like logos, images or text, creating a strong contrast with matte or uncoated areas.

Works on thin and thick paper

Speeds up to 8,000 sheets per hour

Precise and clean coating

Perfect for UV coaters seeking speed, accuracy and dramatic visual effects.

Automatic Spot UV Coating Machines – Video Demo

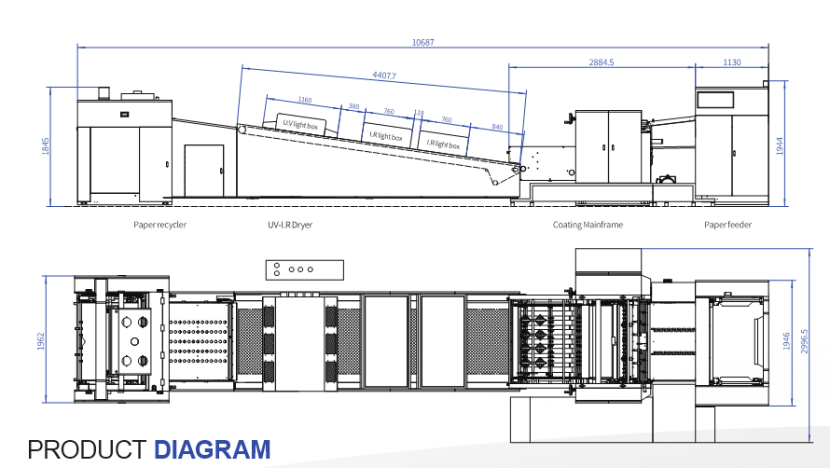

Ty-106W AUTO UV SPOT COATING MACHINE

Discover FENGCHI’s high‑speed Spot UV coating machines with advanced UV varnishing technology. Watch our demo video to see how you can boost throughput and achieve superior finish quality.

Schedule your demo or request a quote today!

Precision in Every Layer, Brilliance in Every Finish

Engineered for Excellence – Every Detail Matters

Automatic Paper Feeder

High-reliability suction heads with linear guide rails for fast and stable feeding.

Double-sheet detector prevents overlapping errors.

Maximum feed pile height: 1,150mm.

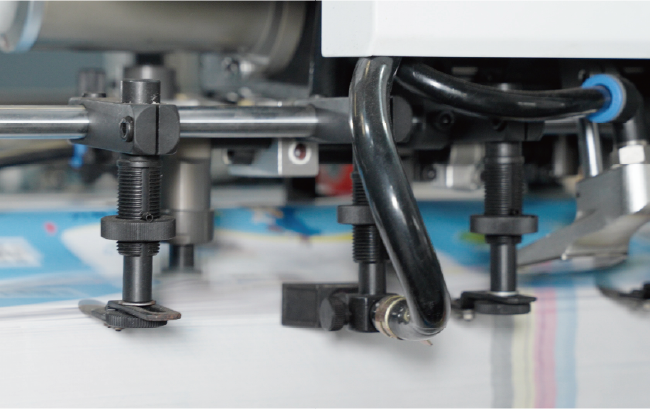

Precision front and side guides ensure accurate paper alignment.

Paper Feeding & Printing Unit

Swing-arm paper feeding mechanism with speeds up to 8,000 sheets/hour.

Coating and impression rollers are finely ground with dynamic balance for high precision.

Quick-change design for coating rollers and plates reduces setup time.

Multi-functional Coating Head

Dual-roller differential structure for smooth, even, and glossy coatings.

Optional ceramic anilox roller and doctor blade system for enhanced coating accuracy.

UV Drying & Curing System

Equipped with 3 UV lamps for efficient curing.

Teflon conveyor belt: quiet, fast, and easy to maintain.

Adjustable full/half lamp modes with UV leakage protection for safety.

Includes temperature control, automatic fault detection, and exhaust cooling system.

Twin IR drying units with 12×1kW lamps in staggered layout for even heat distribution.

Integrated air blower system improves drying uniformity.

Automatic Paper Collector

Automatic paper stacking platform with max pile height of 1,200mm.

Dual photoelectric alignment system ensures neat stacking.

Thin paper guiding mechanism supports smooth collection of lightweight sheets.

Electrical Control System

Full machine driven by Variable Frequency Drive (VFD) and controlled by PLC.

Ensures stable performance with low failure rates.

Get in touch with our experts today

for a free quote or demo!

Product Specifications & Details

Product Details

Equipped with three UV mercury lamps for fast and effective curing.

Optional EB frequency-conversion system reduces energy consumption by 10–15% and prolongs lamp life.

Features automatic temperature control and fault protection system.

Dual-zone IR drying with water-based module for better flexibility.

Gripper-assisted edge correction improves coating consistency and lowers maintenance costs.

Auto-loading table with precise photoelectric-pneumatic edge alignment system.

High-power sheet decelerator prevents misalignment during heavy stacking.

Cooling fans (standard) with optional air-conditioning cooling system.

Multi-status LED indicators and safety monitoring provide real-time feedback.

High-reliability pneumatic feeding head for smooth and fast paper delivery.

Built-in double-sheet detector and foreign object deflector to avoid malfunctions.

Auto-stop protection triggers on anomalies for safety.

Precision guides ensure accurate sheet registration.

- Three UV mercury lamps ensure rapid UV coating curing.

- Teflon mesh conveyor with bottom suction enables quiet, high- speed curing and maintenance ease.

- Full/half-lamp switching and UV leakage protection enhance safety.

- Integrated auto-temperature control, fault trip, and cooling/exhaust systems prevent overheating.

- Dual IR drying groups (12×1kW lamps, staggered layout).

- Auxiliary air-blowing guarantees uniform heat distribution.

- Integrated auto-loading platform with maximum stack height of 1,200mm.

Photoelectric - pneumatic dual-side alignment system for precise stacking.

- Thin-paper guiding device guarantees smooth and orderly sheet delivery.

- High-reliability suction heads with linear slide rails ensure fast paper feeding, tightly delivering sheets of all sizes.

- Sensitive electro-mechanical double-sheet detector automatically stops feeding upon detecting multiple sheets.

- Maximum paper stack height: 1,150mm.

- Precision front and side guides (front guide and pull guide) with quick-adjust mechanisms for accurate positioning.

| Model | TY-106W | TY-1060W-L |

|---|---|---|

| Max. Sheet Size | 740×1050mm (L×W) | 740×1050mm (L×W) |

| Min. Sheet Size | 310×406mm (L×W) | 310×406mm (L×W) |

| Max. Coating Area | 730×1040mm (L×W) | 730×1040mm (L×W) |

| Coating Registration Accuracy | ±0.15mm | |

| Coating Layer Thickness | 0.15mm ~ 0.60mm | |

| Sheet Thickness | 80 ~ 500 gsm | |

| Up to | 6500-8000 sheet/hour (Depends on paper size, dimensions and quality) | |

| Power Required | 40kw (W water-based) | 44kw (E oil-based) |

| Machine Dimension | 10625×2260×2100mm | 13225×2260×2100mm |

| Machine Weight | 7600kg | 8200kg |

Enhance your print and packaging with UV spot coating embellishments

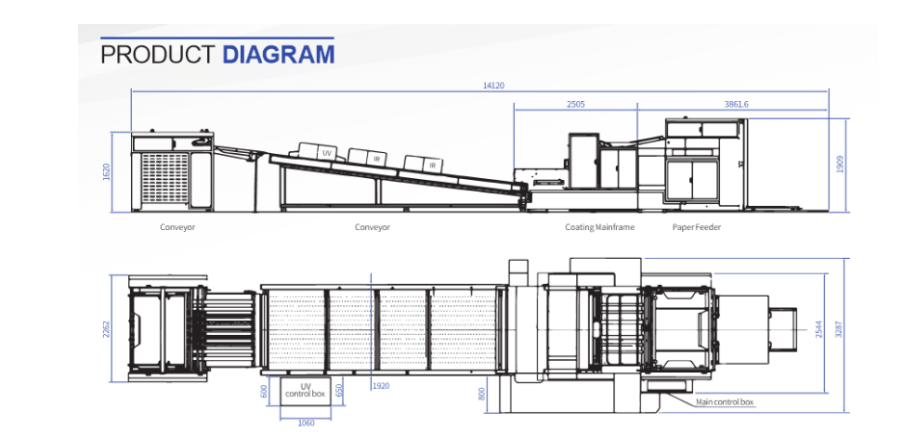

Ty-1460w/Ty-1650W AUTO UV SPOT COATING MACHINE

FENGCHI Ty Series Partial & Spot UV Coating Machines deliver high-quality, consistent finishes on various materials. Featuring precision paper handling derived from offset presses, these machines ensure uniform UV gloss and exact coating thickness control. They handle both lightweight and heavyweight substrates reliably for full or selective (spot UV) coating.

Key benefits include:

Stable UV Curing & Drying: Mesh belt conveyor and large cylinder for even results.

Consistent Coating: Proprietary sealed ink system for reliable application and easy cleaning.

Fast Plate Changes: Quick-release blanket clamp boosts operational efficiency.

Optimize your print finishing with FENGCHI’s Spot UV coating machines—engineered for uniform gloss, precise thickness, and fast setup.

Product Specifications & Details

Product Details

Coating speed: 5,000–6,000 sheets/hour, with up to 30% lower energy and oil consumption.

Compatible with full-surface UV coating, partial adhesive-reserved UV, and water/oil-based coatings.

Large-diameter balanced impression cylinder ensures a uniform coating film.

Dual-axis ink transfer + adjustable doctor blade = precise and reliable ink control.

Quick-release plate clamp: lightweight, durable, easy to maintain.

Bidirectional ink transfer: flexible layer thickness control.

Optional ceramic anilox roller with Danish chambered doctor blade or standard blade for fast cleaning.

Quick-release plate clamping system for fast setup.

Enclosed lightweight doctor blade system + ceramic anilox roller for improved coating precision.

Energy-saving frequency-conversion UV power supply, replacing traditional capacitors.

Simplified mechanical design improves efficiency by 22% over legacy models.

-

VFD (Variable-Frequency Drive) motors ensure safe and stable operation.

-

PLC programmable control for easier operation and maintenance.

-

Quick-disconnect cable connectors for easy installation and servicing.

- Dual-roller differential-speed coating head ensures flat, uniform, and glossy oil film with precision.

- Optional ceramic anilox roller with chambered doctor blade configuration.

Full-machine variable frequency drive (VFD) with PLC programmable controller ensures high stability and low failure rate.

- Swing-arm sheet transfer mechanism supports maximum speed of 8,000 sheets/hour.

- Impression and coating cylinders undergo precision grinding and dynamic balancing calibration for dimensional accuracy.

- Quick-mount system for coating cylinder blankets and plate bases, enabling fast plate changes.

| Model | Ty-1460W | Ty-1650W |

|---|---|---|

| Max. Sheet Size | 1100×1450mm (L×W) | 1300×1650mm (L×W) |

| Min. Sheet Size | 350×460mm (L×W) | 400×460mm (L×W) |

| Max. Coating Area | 1090×1440mm (L×W) | 1290×1640mm (L×W) |

| Coating Registration Accuracy | ±0.15mm | |

| Coating Layer Thickness | 0.15mm ~ 0.60mm | 0.15mm ~ 0.60mm |

| Sheet Thickness | 105 ~ 600 gsm | 120 ~ 600 gsm |

| Up to | Up to 5-6000 sheet/hour (Depends on paper size, dimensions and quality) |

Up to 4-5000 sheet/hour (Depends on paper size, dimensions and quality) |

| Power Required | 68kw/Water-based: oil-based total power | 76kw/Water-based: oil-based total power |

| Machine Dimension | 11800×3400×2300mm | 12840×3400×2360mm |

| Machine Weight | 10200kg | 12000kg |

Interested in an automatic UV spot coating machine?

Contact Form

Phone