Automatic Folder Gluer

High-speed automatic folder gluer with precision engineering for corrugated box production

Automatic Folder

Gluer Machine

High-speed automatic folder gluer for corrugated box production

How the FC Series Delivers Unmatched Performance

What makes the FC Series automatic folder gluer the preferred choice for thousands of customers and agents globally? It’s the fusion of robust engineering with intelligent automation designed for real-world production floors.

High Throughput

Achieve high-volume production with consistent speeds up to 2,500 sheets/hour for AB-type boxes.

Engineered Precision

Motion-control servo positioning ensures registration accuracy within ±1.0 mm, box after box.

Minimize Downtime

Works on A, B, E, F flutes and multi-ply constructions. Quick changeover minimizes setup time when switching sheet sizes or types.

Optimize Labor

Professional delivery line design enables efficient one-person operation, reducing labor costs.

Video Demo — See It in Action

The FC Series automatic folder gluer isn’t just machinery; it’s a strategic investment in your plant’s efficiency and profitability.

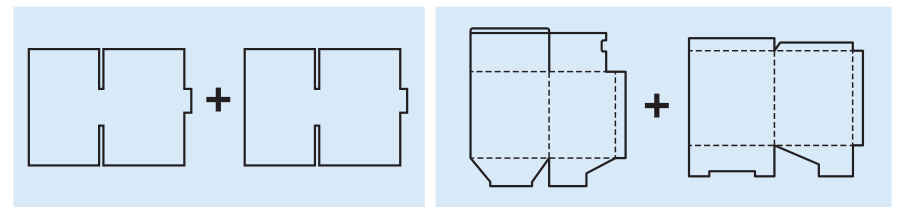

Application

This high-speed automatic folder gluer machine is specially designed for gluing and folding double-piece (AB-type) boxes.

Trusted by Thousands of Customers and Agents

Technical Specifications

| Parameter / Model | FC-2300Z | FC-2600Z | FC-3000Z |

|---|---|---|---|

| Maximum Sheet Size (Single) | 1150 x 1150 mm | 1300 x 1150 mm | 1500 x 1200 mm |

| Minimum Sheet Size (Single) | 550 x 350 mm | 550 x 350 mm | 550 x 350 mm |

| Feeding Pile Height | 400 mm | 400 mm | 400 mm |

| Registration Accuracy | ±1.0 mm | ±1.0 mm | ±1.0 mm |

| Sheet Thickness | E flute to 10 mm | E flute to 10 mm | E flute to 10 mm |

| Power | 16 kW | 16 kW | 16 kW |

| Gross Weight | 4.6 T | 5.0 T | 5.4 T |

| Machine Size (Receiving Parts Exclusive) | 4950 x 3300 x 1800 mm | 4950 x 3800 x 1800 mm | 4950 x 4200 x 1800 mm |

Need a tailored specification? Our sales engineers can configure a solution for your unique site and product requirements.

Product Gallery

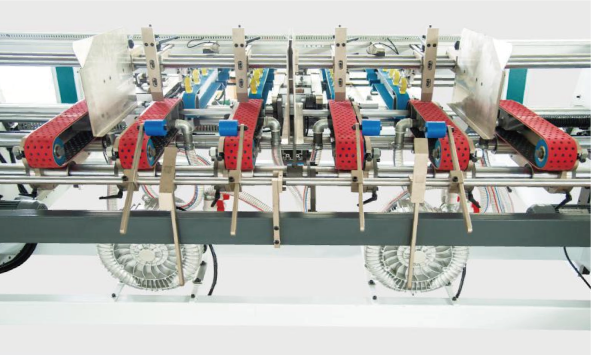

Independent Dual Feeding Mechanism

- Dual suction paper feeding mechanism is independently controlled, providing stable, precise and reliable paper feeding with easy adjustment.

Sheet Delivery Individual Control

- An individual drive structure for AB sheet feeding to avoid scratches.

Alignment System

- A motion-control servo positioning system ensures more accurate carton alignment and faster digital adjustments.

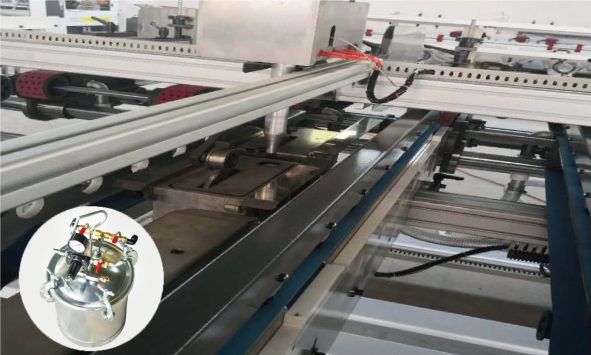

Strong Cohesiveness

- The hot glue is heated by aluminum glue box quickly. Stainless steel bucket stores cold glue to resist corrosion with pressure for automatic gluing.

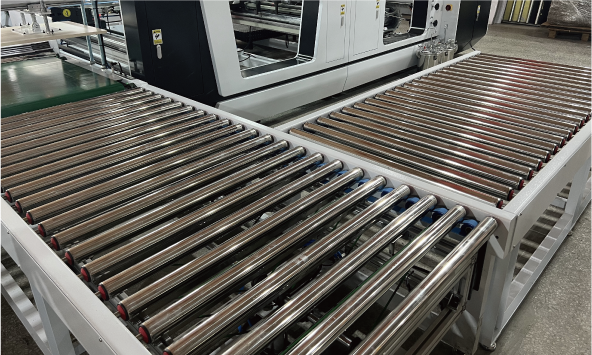

Special Belt Feeder System

- Equipped with four conveying belts to ensure smooth sheet conveying.

Servo Motor Controls Folding

- Use servo motor to fold the carton, with adjustable pressure and stable folding.

Positioning Devices for Easy Adjustment

- Equipped with front and rear positioning devices, which can be easily adjusted according to different products.

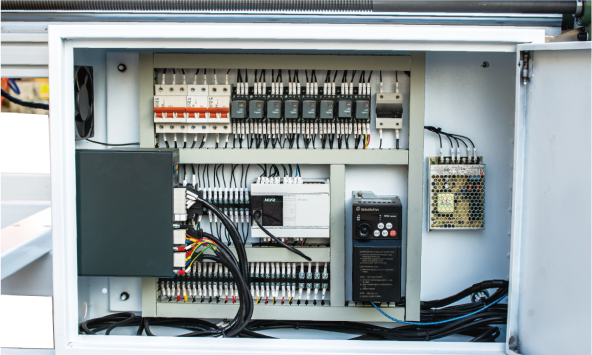

Well-known Brand Electrical Components

- The electrical components are from well-known brands at home and abroad to ensure the normal operation of the machine.

Carton Receiving Line Design

- Professional design enables one-man operation for input and receiving to save the labor cost in production.

Why Partner with Fengchi?

High Quality

Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Vast Experience

More than 15 years of experience within automation gives us an enormous know-how and expertise in laminating solutions.

30 + Patents

We continuously push the boundaries of speed and performance, securing 30 patents through independent research and development.

Global Support

We proudly export corrugated laminating solutions worldwide, ensuring international clients benefit from our innovative technology.

Your Success, Guaranteed by Our Support

Fengchi knows that your success depends on more than just the machine. Our First-Class Service & Support provides the critical tools and knowledge for your team.

Comprehensive Training

We ensure your in-house staff can operate and maintain the machine confidently.

Direct Expert Support

Our technical team is ready to resolve issues remotely or through emergency field visits.

Lifelong Partnership

Ongoing support handled directly by Fengchi to keep your production running.

Request a Quote

We provide expert advice, individual solutions, and complete turnkey systems. Let’s discuss your project.