High-Speed Flute Laminator

Engineered for businesses that refuse to compromise on corrugated board lamination quality.

Meet high-volume demands while maintaining flawless adhesive bonding and superior graphic presentation.

High-Speed Flute Laminator

Engineered for businesses that refuse to compromise on corrugated board lamination quality.

Unmatched Performance and Speed

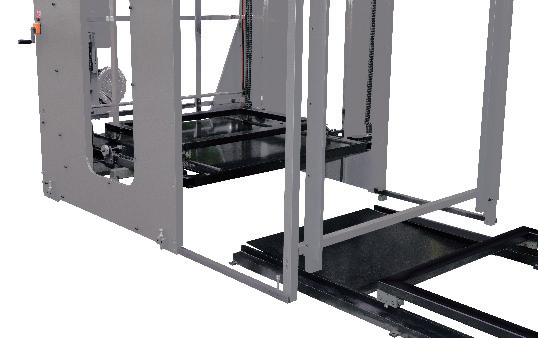

Our state-of-the-art Full Servo High-Speed Flute Laminator is engineered to maximize your output while minimizing waste and downtime.

High Productivity

Maximum laminating speed: 22,000 sheets per hour

Automation

24h production with ultra low manpower needs

Less Waste

Advanced registration control minimizes material waste

Economy

Lowest maintenance costs

Watch Our High-Speed Flute Laminator in Action

Key Benifits

High-Speed Flute Laminator – Up to 22,000 Sheets/Hour

Stable 24/7 Performance: Runs continuously at 16,000 sheets/hour.

Fast Changeover: Quick setup in 2–5 minutes for different batch sizes; boosts production efficiency.

Energy Efficient: Consumes only 8kW/hour – saves up to 20% on power.

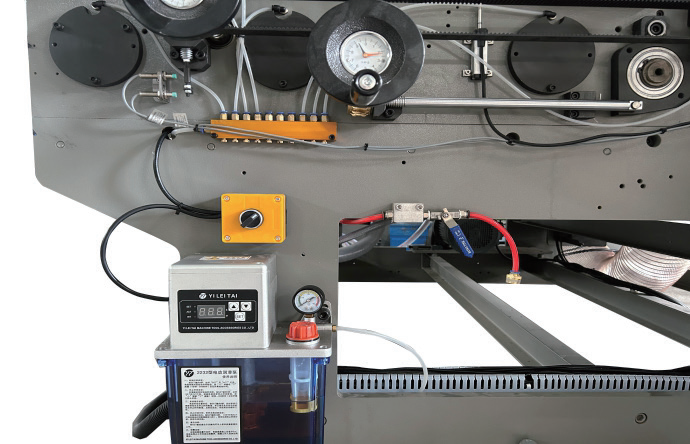

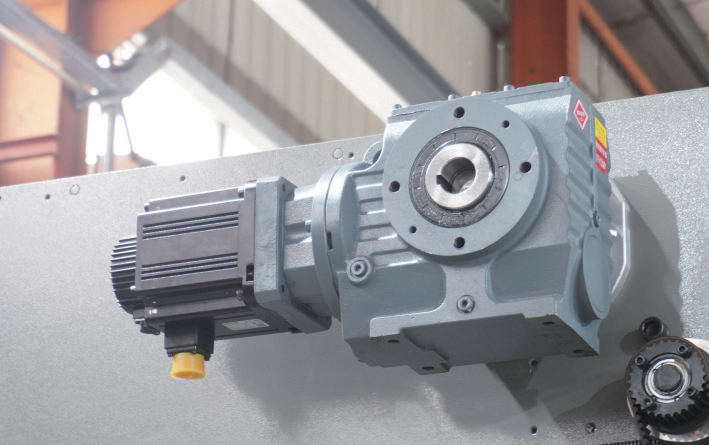

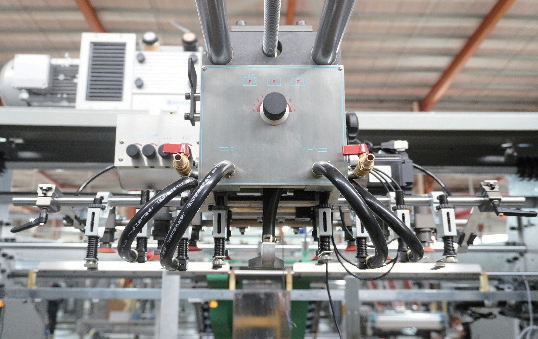

Smart Automation: Digital design with automatic glue and pressure adjustment, self-lubricating bearings; reduces operator skill requirements by 80%.

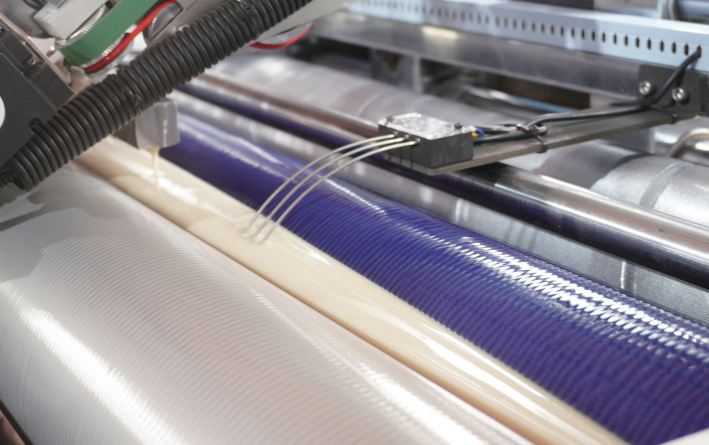

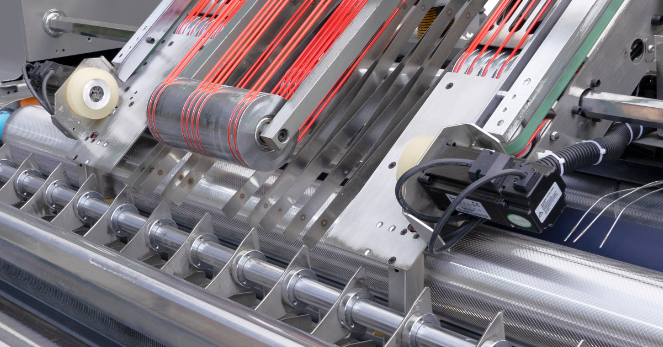

Precise Glue Application: 150mm stainless steel roller, laser-engraved anilox roller applies glue evenly at just 18g/m² – 30% glue savings, no splashing, clean finish.

Full Servo Control: Bus control system ensures high-speed, stable lamination with ±1.0mm accuracy.

Long Lifespan Design: Servo motors and drives built with 35% load reserve for 15+ years of consistent performance.

Product Gallery

Technical Specifications

| Model | GW-1450 Series | GW-1700 Series | GW-2200 Series | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Specifications | GW-1450L | GW-1450LP | GW-1450BP | GW-1700L | GW-1700LP | GW-1700BP | GW-2200L | GW-2200LP | GW-2200BP |

| Max. paper size (W x L) | 1450 × 1450mm | 1700 × 1650mm | 2200 × 2100mm | ||||||

| Min. paper size (W x L) | 360 × 360mm | 360 × 360mm | 450 × 380mm | ||||||

| Bottom Paper Sheet Thickness | F flute-10mm | F flute-10mm | 250gsm - 10mm | F flute-10mm | F flute-10mm | 250gsm - 10mm | F flute-10mm | F flute-10mm | 250gsm - 10mm |

| Upper Paper Sheet Thickness | 150g-700g | 150g-700g | 120g-700g | 150g-700g | 150g-700g | 120g-700g | 150g-700g | 150g-700g | 120g-700g |

| Max. Working Speed | 22,000 Sheets/Hour (175 M/Min) | ||||||||

| Laminating Accuracy | ±1.0mm (Standard Sheet Paper) | ||||||||

| Applicable Glue | Resin adhesive, starch glue and etc (PH6~8 will be suitable) | ||||||||

| Machine Weight | 8000KG | 8500KG | 9000KG | ||||||

| Dimension (L×W×H) | 15700 × 2400 × 2550mm | 16300 × 2650 × 2550mm | 18500 × 3050 × 2880mm | ||||||

| Power Supply | 380V/3P | ||||||||

| Machine Power | 26KW | 30KW | 32KW | ||||||

| Applicable Corrugated Board | A, B, C, E, F, 3ply, 5ply, 7ply corrugated board, and cardboard within above mentioned thickness range | A, B, C, E, F, 3ply, 5ply, 7ply corrugated board, and cardboard within above mentioned thickness range | Cardboard above 250gsm, and A, B, C, E, F, 3ply, 5ply corrugated board | A, B, C, E, F, 3ply, 5ply, 7ply corrugated board, and cardboard within above mentioned thickness range | A, B, C, E, F, 3ply, 5ply, 7ply corrugated board, and cardboard within above mentioned thickness range | Cardboard above 250gsm, and A, B, C, E, F, 3ply, 5ply corrugated board | A, B, C, E, F, 3ply, 5ply, 7ply corrugated board, and cardboard within above mentioned thickness range | A, B, C, E, F, 3ply, 5ply, 7ply corrugated board, and cardboard within above mentioned thickness range | Cardboard above 250gsm, and A, B, C, E, F, 3ply, 5ply corrugated board |

* If you need more detailed data, you can consult our experts.

Final Product Samples

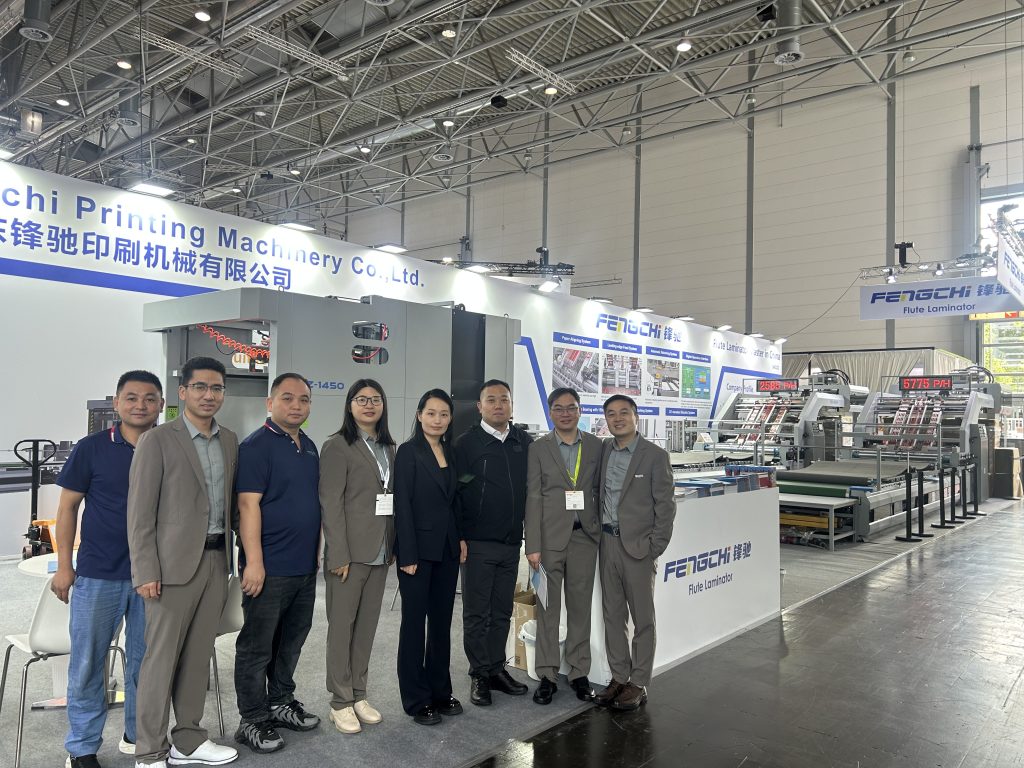

Why Partner with Fengchi?

High Quality

Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Vast Experience

More than 15 years of experience within automation gives us an enormous know-how and expertise in laminating solutions.

30 + Patents

We continuously push the boundaries of speed and performance, securing 30 patents through independent research and development.

Global Support

We proudly export corrugated laminating solutions worldwide, ensuring international clients benefit from our innovative technology.

What Our Customers Say

Hear from industry leaders who have transformed their production with our high-speed flute laminators

We’ve increased our daily output by 45% while reducing material waste. The ROI was achieved in just 10 months.

– John Smith, Production Manager

The technical support is exceptional. When we had a minor issue, their team resolved within 24 hours.

– Maria Johnson, Operations Director

The precision and consistency of the flute laminator have significantly improved our product quality.

– Robert Williams, CEO

Trusted by Industry Leaders Worldwide

Fengchi Service

Expert Service & Support

Fill in your details and our sales engineer will contact you shortly.

Contact Form

Phone