Auto Cardboard Laminator

Up to 10,000 sheets/hour with ±0.5 mm full-servo accuracy

— built for high-volume packaging production.

Auto Cardboard Laminator

Built for high-volume packaging production.

Why Choose Automatic Cardboard Laminator

More than just a machine — it’s a strategic investment in your production future with comprehensive support from industry experts.

High-Speed Production

Achieve maximum laminating speeds of up to 10,000 sheets per hour, dramatically increasing your output capacity.

High Accuracy

Full servo-controlled system with ±0.5mm laminating accuracy ensures perfect alignment and eliminates material waste.

Quick Setup

Change jobs in just 2-5 minutes with automated adjustments based on paper size and thickness inputs.

Full Automation

One-key operation controls feeding, laminating, and collection with minimal operator intervention required.

Glue-Saving Design

High-precision glue roller system reduces adhesive consumption to just 18 g/m² while ensuring perfect bonding.

Wide Compatibility

Using a front feeder suitable for the thinnest top paper 100gsm and thinnest

bottom paper 200gsm.

Video Demo — See It in Action

Technical Specifications

| Parameter / Model | GK-1307 | GK-1310 |

|---|---|---|

| Max Paper Size | 1300 × 720 mm | 1300 × 1000 mm |

| Min paper size | 500 × 350 mm | |

| Top paper thickness | 100-700gsm | |

| Bottom paper thickness | 200-900gsm | |

| Max. Working Speed | 10000 Sheets/hour | 7800 Sheets/hour |

| Laminating Accuracy | ±0.5mm (Standard Sheet Paper) | |

| Applicable Glue | Starch glue, resin glue, milky glue etc., (PH value 6-8) | |

| Machine weight | 6500kg | |

| Machine size | 9900 × 2250 × 2180 mm | |

| Input voltage | 380 VAC/3P | |

| Power | 20kw | |

| Applicable paper | Thin paper, cardboard paper; coated paper; gray board, thick paperboard etc. | |

Note: Specifications are subject to change. Please consult with our team for the most current and detailed information.

Product Gallery

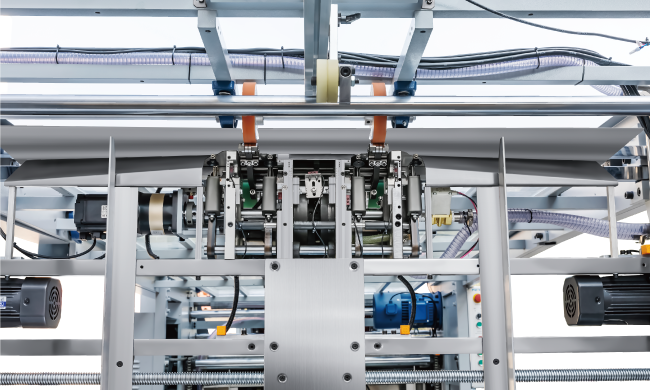

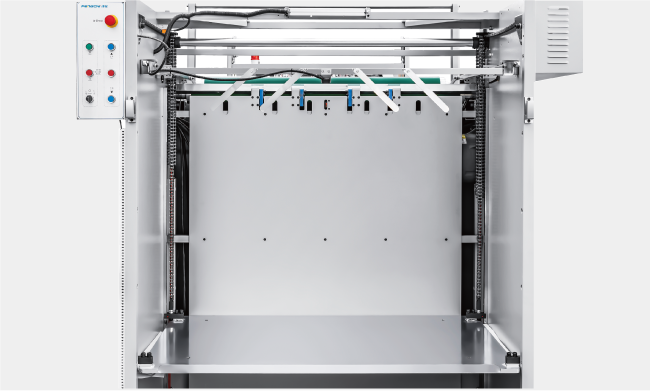

Laminating Part

- The paper lamination alignment adopts differential speed tracking; the top and bottom papers are simultaneously conveyed to the alignment guide, ensuring accurate lamination.

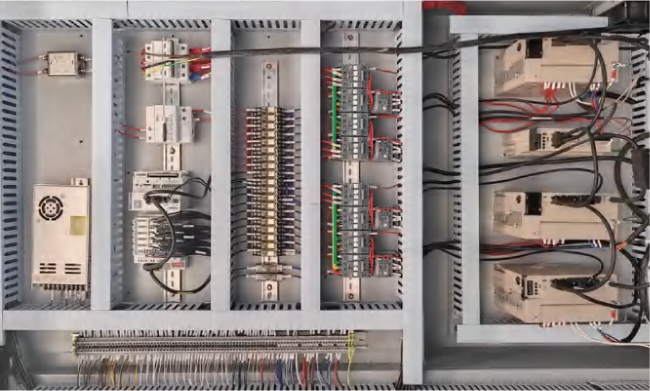

Electric System

- Uses well-known components from both domestic and international brands, designed to meet CE standards, and supports remote control with equipment upgrades.

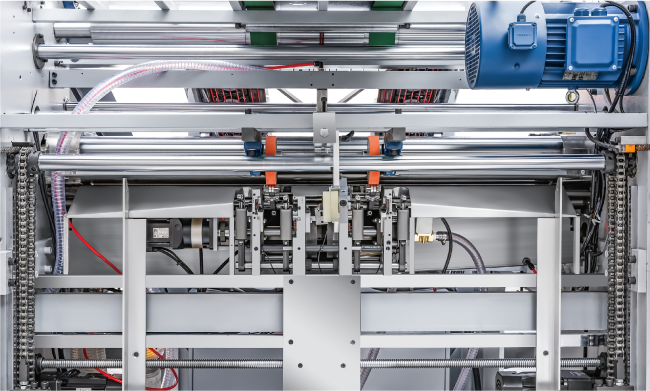

Feeding System

- Uses a 360-degree rotating high-speed front suction servo feeder equipped with a 4.0 kW vacuum pump to ensure faster, more stable paper feeding and smoothly handle both thick and thin papers.

Servo-controlled Stacking System

- Uses a servo control system that allows each lift or drop speed to be freely adjusted, ensuring stable, smooth, and seamless conversion.

Aligning System

- A full-servo tracking system ensures stability and achieves ±0.2 mm high-precision alignment.

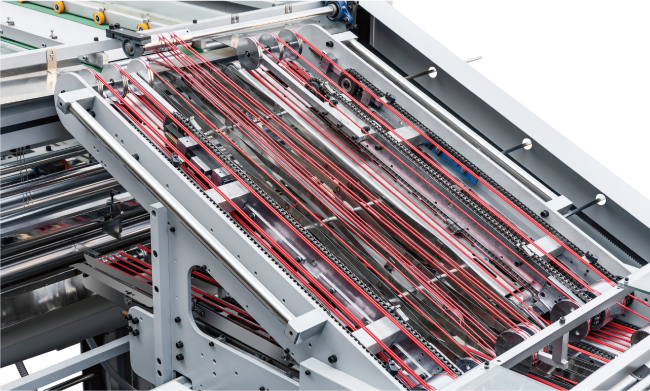

Paper Collecting System

- Laminated paper is automatically stacked and transported via forklift, thereby reducing labor costs by 30% to 50%.

Why Partner with Fengchi?

High Quality

Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Vast Experience

More than 15 years of experience within automation gives us an enormous know-how and expertise in laminating solutions.

30 + Patents

We continuously push the boundaries of speed and performance, securing 30 patents through independent research and development.

Global Support

We proudly export corrugated laminating solutions worldwide, ensuring international clients benefit from our innovative technology.

First Class Service & Support

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines. Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.