GW BP Series Flute Laminator

Engineered for unmatched speed, accuracy, and efficiency.

Ideal for corrugated and paperboard packaging production.

GW BP Series Flute Laminator

Ideal for corrugated and paperboard packaging production.

Key Benefits

Fengchi specializes in developing, manufacturing, and marketing automatic flute laminators for printing and packaging manufacturers. The GW BP Series is the upgraded, fully servo flute laminator engineered for unmatched speed, accuracy, and efficiency. Engineered for 24/7 operation, it’s built to deliver consistent performance while reducing power, labor, and material costs.

High-Speed Performance

Up to 22,000 sheets/hour with stable continuous operation at 16,000 sheets/hour.

One-Button Operation

Fully automated job changeover in just 2–3 minutes with minimal operator intervention.

Intelligent Automation

±0.5mm Registration control minimizes material waste

Energy Efficient

Consumes only ~8 kWh, saving approximately 20% on power compared to conventional models.

Extended Machine Life

Built with 35% margin on servo load, ensuring accuracy and durability for over 15 years.

Quick ROI

Energy savings, reduced glue use, and less downtime accelerate your investment return.

See Our Machine in Action

Fast, Accuracy, Stable Turnkey Solution!

Our GW BP Series Flute Laminator delivers high-speed, accuracy, and stable turnkey solutions for small, medium, and large-scale production runs. Perfect for businesses seeking to boost productivity and reduce costs with a cutting-edge, corrugated laminating solution.

Final Product Samples

Read Installation Case Study

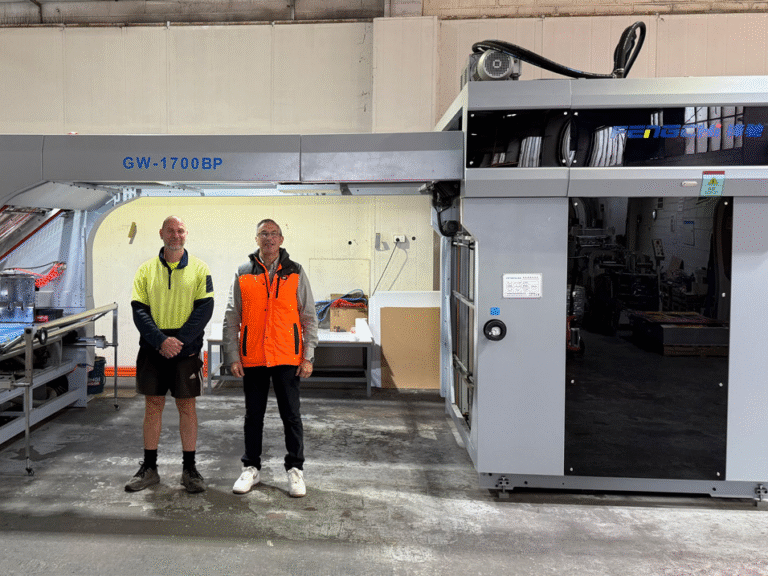

PMS Lithography installs Fengchi GW1700 litho laminating machine

PMS Lithography was using other mounting equipment prior to acquiring the Fengchi GW1700, but according to Prosenica, it lacked speed.

“We needed to increase our productivity, and the Fengchi GW1700 provides that for us. We’ve kept the other equipment as backup, but we haven’t had to use it even for increased workloads as this machine is more than capable of doing the work. We’ve reduced the workload from two shifts to one, which has been a major advantage for us,” Prosenica said.

Choose Your Model

GW-1450BP Flute Laminator

Model: GW-1450BP

Automatic Grade: Automatic

Membrane Material: Paper

Performance: Anticorrosive

Patent: Leading Edge Paper Feeding Patent

Stable Speed: 16,000 Sheets/Hour

Advantages: Low Failure Rate, High Efficiency, Long Life

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

GW-1700BP Flute Laminator

Model: GW-1700BP

Automatic Grade: Automatic

Membrane Material: Paper

Performance: Anticorrosive

Patent: Leading Edge Paper Feeding Patent

Stable Speed: 16,000 Sheets/Hour

Advantages: Low Failure Rate, High Efficiency, Long Life

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

GW-2200BP Flute Laminator

Model: GW-2200BP

Automatic Grade: Automatic

Membrane Material: Paper

Performance: Anticorrosive

Patent: Leading Edge Paper Feeding Patent

Stable Speed: 16,000 Sheets/Hour

Advantages: Low Failure Rate, High Efficiency, Long Life

After-sales Service: Engineers Available Video & Videoconference Remote

Warranty: 1 Year

* Not sure which flute laminator machine is best suited to your needs? Contact our experts.

Technical Specifications

Belt Feeder Version

| Model | GW-1450BP | GW-1700BP | GW-2200BP |

|---|---|---|---|

| Max Sheet Size | 1450 × 1450 mm | 1700 × 1650 mm | 2200 × 2100 mm |

| Min Sheet Size | 360 × 360 mm | 360 × 360 mm | 450 × 380 mm |

| Max Speed | 16,000 sheets/hr (165 m/min) | ||

| Laminating Accuracy | ±1.0 mm (Standard Sheet Pape) | ||

| Applicable Glue | Resin adhesive, starch glue,milky glue (PH 6~8 will be suitable) | ||

| Machine Weight | 8,000 kg | 8,500 kg | 9,000 kg |

| Dimension (Lx W x H) | 15,700 × 2,400 × 2,550mm | 16,300 × 2,650 × 2,550 mm | 18,500 × 3,050 × 2,880 mm |

| Voltage | 380 VAC/3P | ||

| Power | 20kW | 20kW | 23kW |

| Bottom Paper Applicable | Cardboard above 300gsm, and A, B, C, E, F, 3ply, 5ply corrugated board | ||

* Also available in Leading Edge Feeder configuration.

Product Highlights

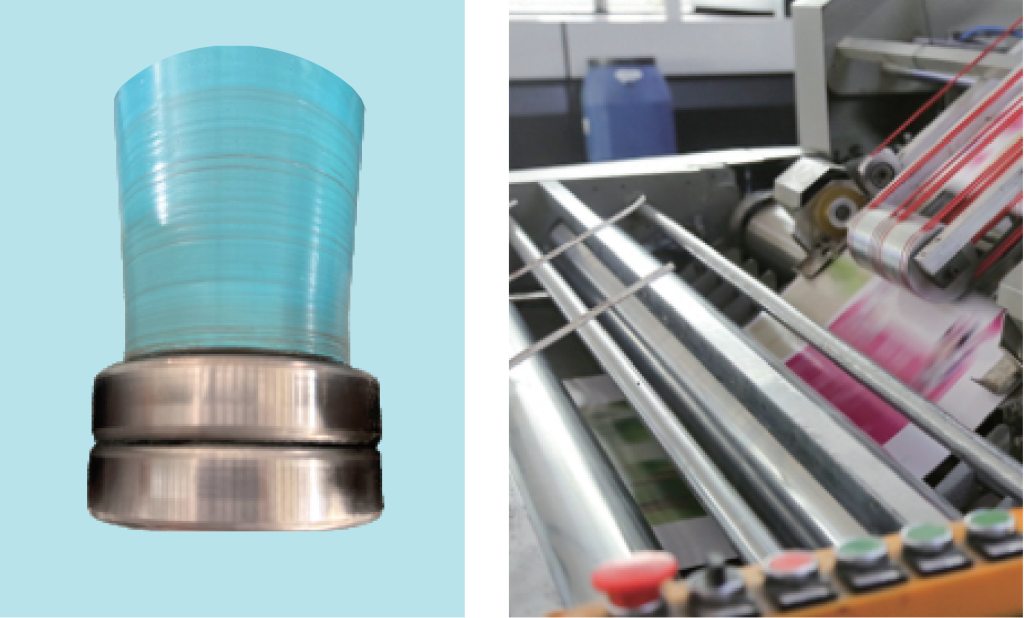

PU Bottom Feeding Wheel

- Unidirectional rotating feeding roller, without wear and tear, service life cycle up to 10 years.

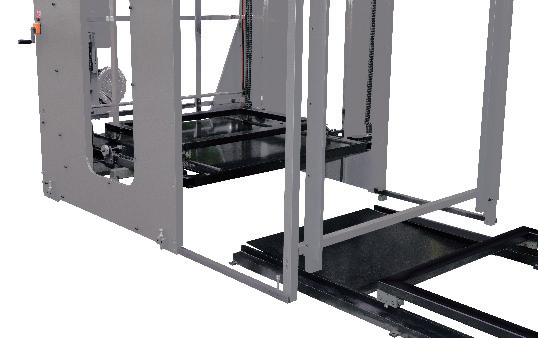

Leading-edge Feed System

- Self-developed leading-edge feed system specially for deformed, warped corrugated papers.

One-button Operation

- Adopting 7-8 servo motors control systems, digital intelligent input, automatic order changeover in 2-3 min.

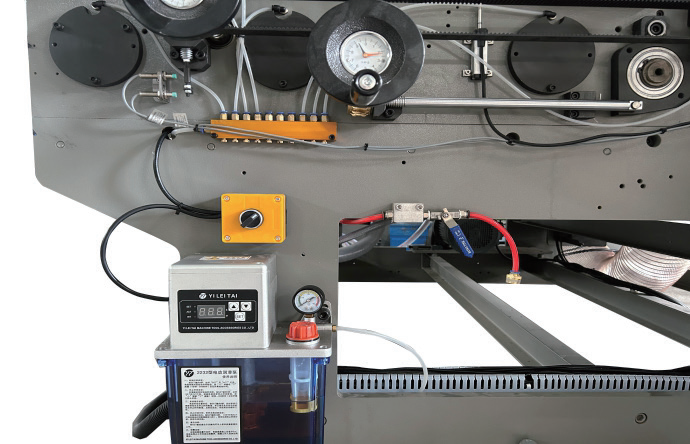

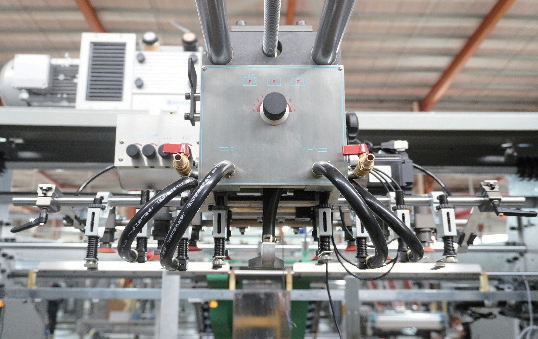

Automatic Lubrication of Bearings

- Intelligent control for automatic lubrication, no need for daily maintenance, saving labor costs, and improving production efficiency.

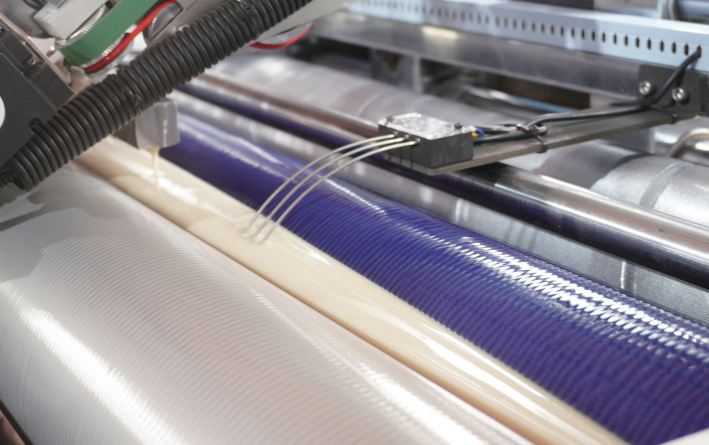

Enlarged Glue Roller

- Enlarged 150mm diameter stainless steel roller, laser engraved anilox, high-speed and stable without glue splashing.

Servo Control Lifting Pile Plate

- High speed feeder smooth feeding, single sheet lifting same as offset printing press, high efficient and stable.

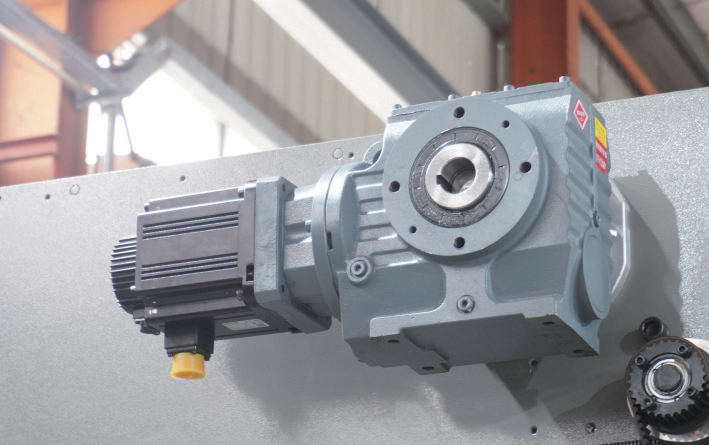

Dual-bearing Structure

- Ensures efficient and stable operation of the machine with doubled life cycle.

Pre-stacking System

- Whole pallet loading platform, saving labor costs and time.

Shaft-less High Speed Feeder

- Servo controlled high-speed shaft-less feeder front-and-rear auto-adjustment.

Why Partner with Fengchi?

If you are looking for a reliable and fully automatic high-speed flute laminator, Fengchi is the right supplier for you.

High Quality

Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Vast Experience

More than 15 years of experience within automation gives us an enormous know-how and expertise in laminating solutions.

30 + Patents

We continuously push the boundaries of speed and performance, securing 30 patents through independent research and development.

Global Support

We proudly export corrugated laminating solutions worldwide, ensuring international clients benefit from our innovative technology.

What Our Customers Say

Hear from industry leaders who have transformed their production with our high-speed automatic flute laminators

We are extremely pleased and proud to have acquired the top flute laminator in China from Fengchi. It’s an exciting milestone for us to have the best in the industry.

I also want to extend my gratitude for the exceptional senitce and smooth negotiation process we’ve experienced. Congratulations to both our teams for this achievement!

Best regards.

– JULIO Julio Miamau, CEO

We have partnered with this company for years and have never been disappointed. Both the product quality and responsiveness of their service are outstanding. Every delivery meets our high standards, giving us a competitive edge in the market. They are truly a trustworthy partner.

– Farhan Mathur, Operations Director

I really like FENGCHI’s machines. These machines are easy to operate, and the finished products are very good.

– Haluk Önder, Operator

Trusted by Industry Leaders Worldwide

Major Suppliers

Our Technical Service

After Sales service begins with the arrival of the machinery at the customer’s factory.

To maximize investment whether a single machine or an entire line, the equipment needs to enter the existing production quickly and deliver its contribution. Fengchi offers a dedicated team of technicians that assemble, calibrate and commission the machinery.

Our engineers teach customer operators the machines function, calibration, available options, best practice and scheduled housekeeping.

Fengchi is always available to its customers if they have a problem, concern or malfunctionwith their machinery.

Frequently Asked Questions

Why choose us to cooperate?

1. “FENGCHI” is well-known brand and paper flute laminator master in China since 2009, focus on solving the manufacturing process of over-gluing and laminating & stacking after the post-printing of color cardboard & corrugated cartons.

2. Strong R&D team by 25 senior engineers over 30 years experience in printing industry. With 30 patents to ensure product more stable, more efficient and durable.

3. After-sale service and technical assistance: company provides after sales service and technical assistance as per customers’ requirement and needs with response within 24 hours.

4.Cost saving: Full servo digital operating system greatly reduce operator level(normally two primary operator) with manpower saving, 150mm roller with double bearing and auto refueling system make equipment durable and free maintenance. China highest laminating speed at 22,000pcs/hour.

Are you a manufacturer?

Yes, we are Flute Laminator Master from China over 15 years, specialize in automatic flute laminators and flip flop stackers.

Do you have stock products to sell?

We produce machines in bacth normally. So most models we have some in stock, please check with us before ordering.

How about warranty?

Warranty period: 12 months from the shipping date of machine. Warranty will be not valid if machine subject to misuse or accidental damage or operator’s error. During the valid time, we will supply spare parts. If you have any other questions, pls contact us and we will reply you through product’s photos and videos to make every detail clear. We also provide all lifetime warranty with paid service.

How about installation and training?

Normally, one operator can finish intallation in 2 hours with installation manual and video. If purchaser’s engineer travels at own cost to China, free training session. If engineer sent to purchaser’s factory, all travel cost paid by purchaser.

Do you test all your goods before delivery?

Yes, we have 100% functional testing and pilot run before delivery to ensure product integrity. All products are certificed by CE.

What is your delivery time?

Our delivery time is 10-30 working days after receiving full payment or deposit. The specific delivery time depends on the product and the order quantity.

What are your packaging conditions?

Usually, we pack the machine in a container with a plastic bag with desiccants, then with strong seaworthy wooden cases. Each machine will be protected by anti-rusted oil before put into case.

Will you supply for OEM orders?

Yes, we can customize the production machine according to your requirements.

Request a Quote

Get efficient corrugated laminating solutions and a personalized quote within 24 hours.