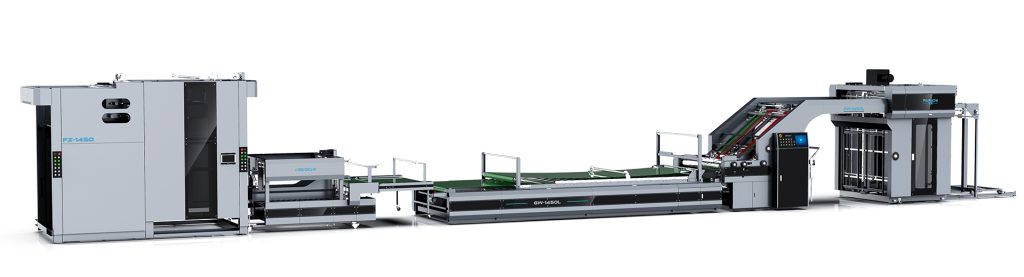

Flute Laminator with Stacker

Boost throughput up to 22,000 sheets/hour, maintain ±0.5mm alignment accuracy and fully automate stacking for corrugated litho lamination and carton conversion.

Flute Laminator with Stacker

Boost throughput up to 22,000 sheets/hour, maintain ±0.5mm alignment accuracy

Why This Flute Laminator?

Engineered for continuous high-volume production, this full-servo flute laminator combines speed, precision, and robust automation — reducing labor and increasing throughput.

Full-servo Drive

Digital servo synchronization for feeder, gluing and stacker — precise control at top speed.

High Throughput

Up to 22,000 sheets/hour — eliminate production bottlenecks.

Stacker Machine ( Optional)

Fully automated stacker neatly stacks laminated board on the pallets, preparing it for the next production phase. This reduces manpower and downtime.

Robust Build

Industrial components for 24/7 operation and low maintenance.

Easy Control

PLC + touchscreen HMI with recipe memory for fast job changeovers.

High Precision

Multi-sensor alignment and ±0.5mm positioning tolerance for repeatable quality.

See Our Flute Laminator With Stacker in Action

Watch how our high-speed flute laminator with flip-flop stacker revolutionizes corrugated board laminating production.

End-use Applications

Our automatic flute laminating machine with flip flop stacker is widely used in the printing and packaging industry.

For example: corrugated litho lamination, carton converting and folding, POP displays and packaging, e-commerce protection packaging, high-volume label and graphic lamination, etc.

Case Study — Successful Installation of GW-1700LP Flute Laminator with Stacker in Australia

Fengchi Printing Machinery has completed the successful installation and commissioning of its first flute laminating machine production line in Australia — a milestone that demonstrates how targeted customer service, field testing and high-quality engineering combine to meet demanding production needs. The Australian client chose the GW-1700LP high-speed flute laminator plus a full-servo flip-flop stacker, replacing an older competitor machine to gain speed, reliability and automation.

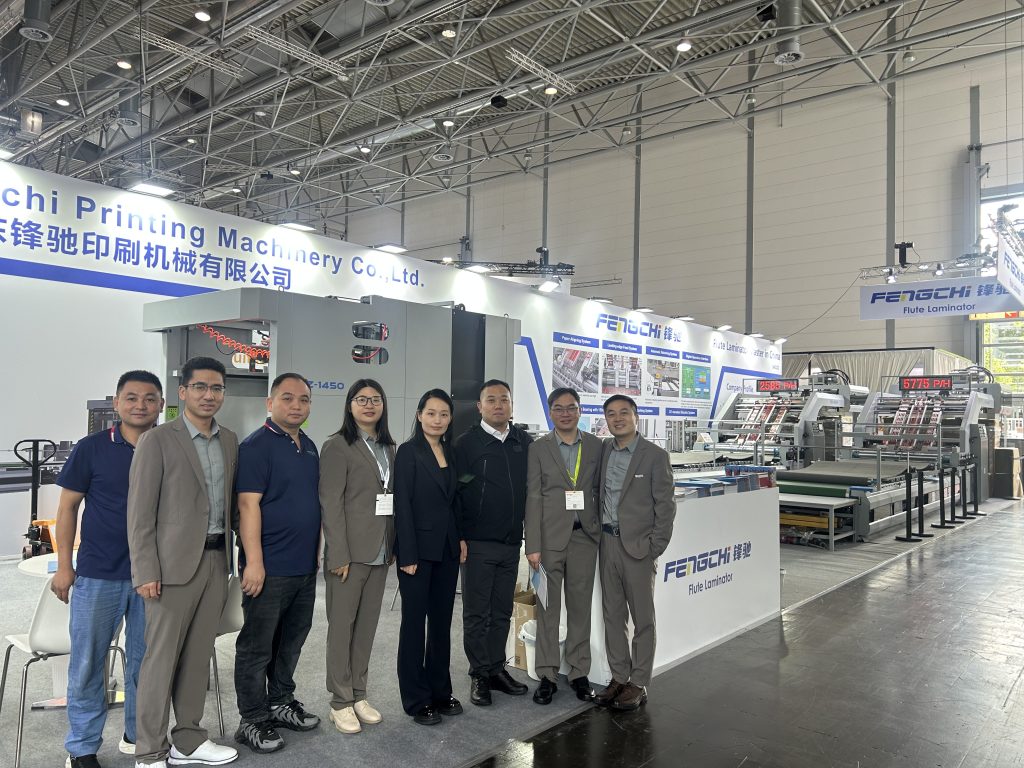

Your Reliable Partner for Flute Laminator

Increase Productivity

By automating your corrugated laminating process, we deliver an accurate and consistent lamination, reducing waste and minimizing downtime.

15+ Years of Experience

More than 15 years of experience within automation gives us an enormous know-how and expertise in laminating solutions.

Reliable Solutions

We deliver reliable and easy-to-operate solutions of high quality that help our customers optimize their packaging line.

Global Service

We provide installation and service support wherever your operations are located.

Trusted by Industry Leaders Worldwide

What Our Customers Say

Hear from industry leaders who have transformed their production with our high-speed flute laminators

We eliminated over two operators per shift thanks to automated stacking and alignment. Output nearly doubled in the first month.

– John Smith, Production Manager

The technical support is exceptional. When we had a minor issue, their team resolved within 24 hours.

– Maria Johnson, Operations Director

The precision and consistency of the flute laminator have significantly improved our product quality.

– Robert Williams, CEO

Expert Service & Support

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines.

Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

Unsure Which Automatic Flute Laminator to Choose?

Don’t worry! We understand that it can be challenging to find the perfect custom flute laminator. That’s why our dedicated sales engineers are here to support you.

- Expert advice on choosing the best flute laminator and flip flop stacker for your unique needs.

- Complete professional guidance before, during, and after your purchase.

- Assistance with any questions regarding delivery times, installation, and training.

Hello, let's talk about high-speed flute laminator!

Contact Form

Phone