Chonburi, Thailand – January 13, 2026 – In a rapidly evolving Thai packaging market saturated with mid-tier players, one Chinese-owned factory is rewriting the rules. During a recent visit to LETAI PACKAGING (THAILAND) CO., LTD. in Chonburi, we witnessed a facility defying industry norms: a high-end production hub built from zero clients, operating at full capacity within 12 months, and already planning its second expansion phase. This isn’t just another foreign investment—it’s a masterclass in strategic overseas market entry.

Why LETAI PACKAGING stands out in Thailand’s competitive landscape

Unlike most overseas packaging ventures that target existing clients of parent companies, LETAI PACKAGING started with zero client base. Founded by Qingdao Lezhitai Industrial Co., Ltd. (China), the Chonburi facility began construction in 2024 and launched production in early 2025. Today, it’s already outgrowing its 10-acre site—a testament to its disruptive approach.

Key Differentiators:

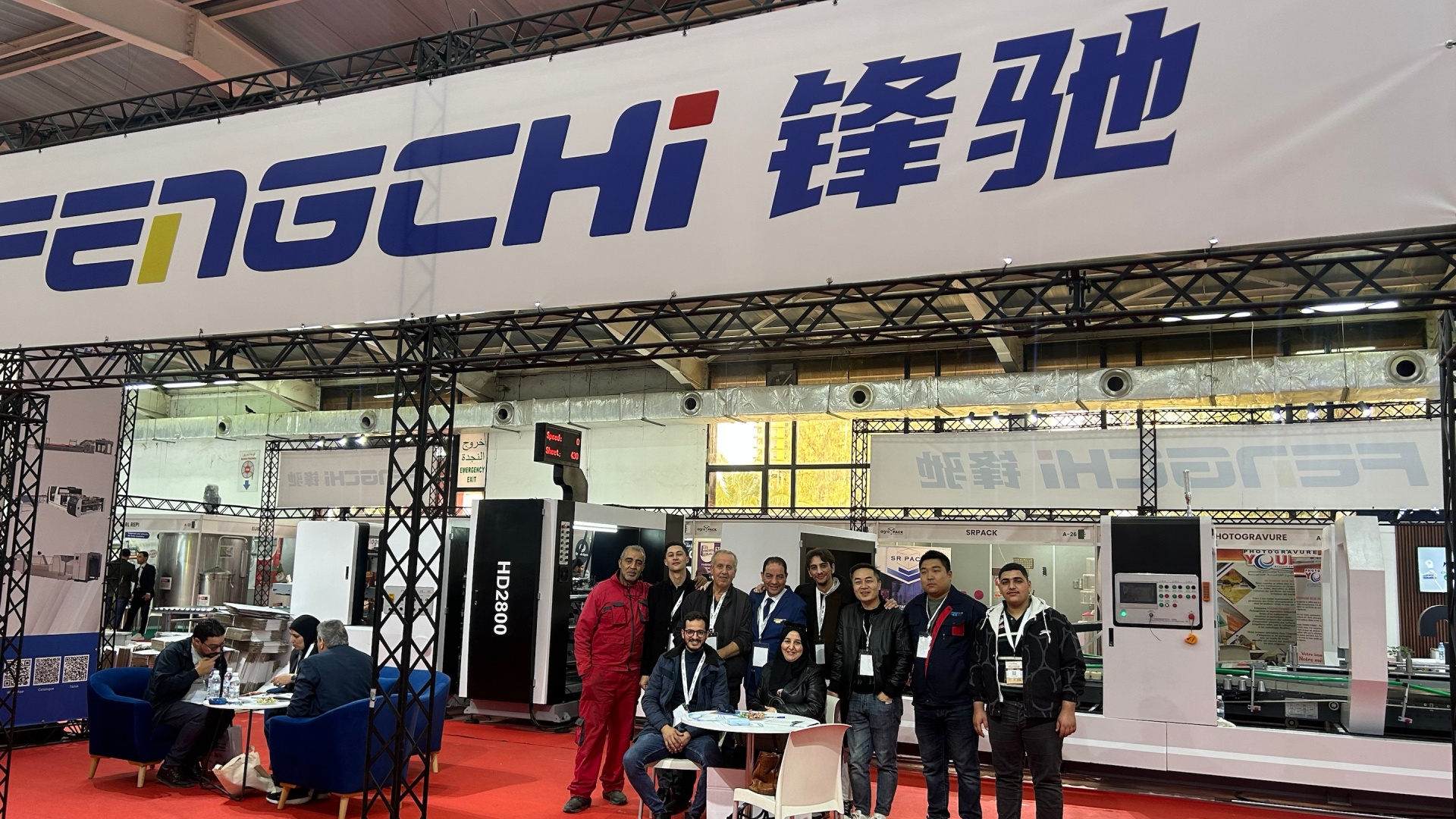

✅ High-End Equipment Focus: Only premium machinery, including two Guangdong Fengchi intelligent high-speed litho laminating machines—the industry’s gold standard.

✅ Niche Specialization: 80% of output is premium corrugated color boxes and cartons; the rest are custom color-printed cardboard boxes.

✅ Service-First Culture: Flat management with dedicated client service teams ensuring 24/7 responsiveness.

✅ Strategic Market Targeting: Focusing on Thailand’s underserved high-end segment instead of competing on price.

Thailand’s packaging market: saturation vs. premium opportunity

Mr. Xiao’s insight cuts to the heart of Thailand’s packaging reality:

“Domestic competition is at saturation—growth is limited. But emerging markets crave personalized premium packaging. When you elevate service, you’re not competing—you’re showcasing capability.”

LETAI’s model proves this. By prioritizing high-end production quality (backed by Fengchi’s cutting-edge tech) and hyper-responsive client service, they’ve bypassed price wars entirely. Their 80% focus on premium corrugated boxes aligns perfectly with Thailand’s growing luxury retail and e-commerce sectors—where brands demand packaging that enhances brand value, not just protects products.

The Roadmap: From Zero to Expansion in 12 Months

| Milestone | Timeline | Result |

|---|---|---|

| Construction Start | Q1 2024 | 10-acre Chonburi facility built |

| Production Launch | Early 2025 | Full capacity within 6 months |

| First Expansion Plan | Q1 2026 | Second phase underway |

This rapid trajectory—unthinkable in a “slow-growth” market—stems from three pillars:

- Deep Market Understanding: Leveraging China’s packaging ecosystem to anticipate Thai client needs.

- Asset Efficiency: Fengchi’s high-speed machines maximize output without compromising quality.

- Client-Centric DNA: Dedicated service groups ensure every client feels prioritized.

Why this case study matters for global packaging brands

LETAI PACKAGING isn’t just thriving—it’s redefining success for Chinese enterprises expanding overseas. In a market where 70% of foreign packaging firms struggle with client acquisition (per Thailand Packaging Association 2025), their “build from scratch” model offers a replicable blueprint:

“Focus on service, target premium, and let quality speak. The market will follow,” says Mr. Xiao. “This isn’t about being the biggest—it’s about being the best for the right clients.”

Stay Ahead: Guangdong Fengchi’s Global Factory Tour

LETAI PACKAGING’s journey is a featured case study in Guangdong Fengchi’s Global Factory Tour—a series designed to guide packaging enterprises on overseas expansion. Discover how high-end equipment, strategic market entry, and service innovation create unstoppable growth.

👉 Explore Guangdong Fengchi’s Global Factory Tour for actionable insights on premium packaging expansion.

FAQ

Q1: When did LETAI PACKAGING start production?

A1: Construction began in 2024 and production commenced in early 2025.

Q2: What percentage of LETAI’s production is corrugated color boxes?

A2: Approximately 80% of production is corrugated color boxes and color cartons.

Q3: What equipment does LETAI use?

A3: LETAI is equipped with two Guangdong Fengchi intelligent high-speed litho laminating machines among other high-end brands.

Q4: Why is LETAI expanding despite starting from zero clients?

A4: LETAI’s premium positioning, strong service model, and fast customer acquisition have driven demand and necessitated phase-two expansion.

Q5: What lessons can other manufacturers learn from LETAI?

A5: Focus on premium products, invest in reliable high-end equipment, organize client-centric service teams, and plan for scalable site capacity.

How LETAI PACKAGING (Thailand) built a premium packaging empire from zero clients in 12 months. Case study on high-end equipment, service-first strategy, and market opportunity in saturated Thailand. Learn from Guangdong Fengchi’s Global Factory Tour.