Model P Window Patcher

Flat patch windows at up to 36,000 sheets/hr — built for high-volume folding carton production

Model P Window Patcher

Flat patch windows at up to 36,000 sheets/hr — built for high-volume folding carton production

Key Features & Benefits

For converters and packaging producers seeking efficiency and precision, the Model P delivers unmatched performance for folding cartons. It combines speed, stability, and accuracy — reducing waste and labor costs.

High-Speed Output

Up to 36,000 sheets/hour continuous operation ensures your production never falls behind schedule.

Precise Film Placement

Servo control maintain ±1mm alignment for perfectly centered windows.

Seamless Integration

Compatible with folder gluers and downstream lines for end-to-end packaging automation.

Fast Setup

Digital settings with one-touch controls for glue application, film feeding, and cutting parameters.

Long-Term Durability

Built with 35% load-reserve servos and components designed for over 15 years of operation.

Synergistic Drive System

9 synchronized servos working in harmony for smart, efficient operation and minimal energy consumption.

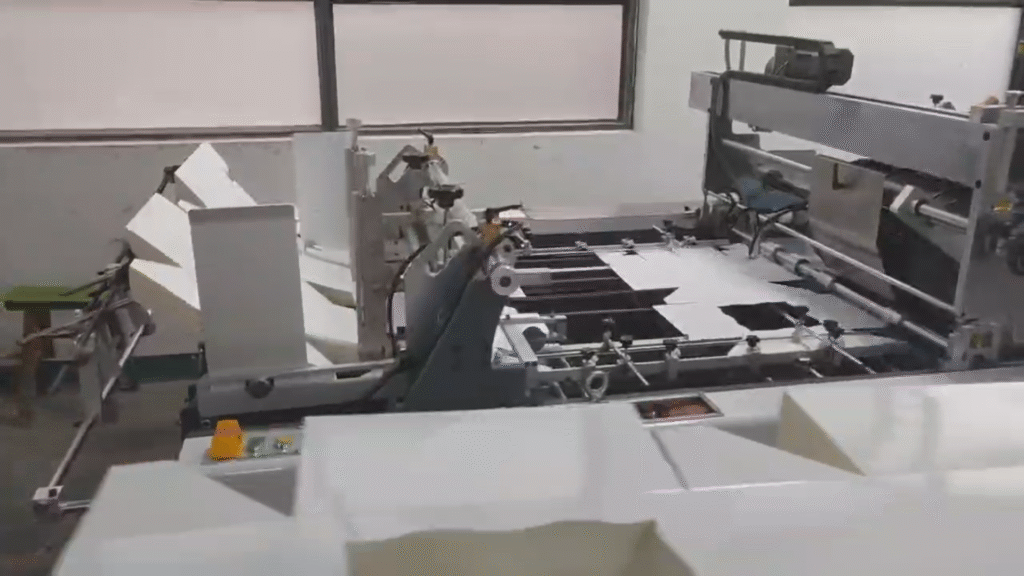

See Model P Window Patcher in Action

Final Product Samples

The Model P Window Patcher is engineered for precision across diverse packaging requirements

Versatile for a wide range of industries including consumer goods, retail, food, and industrial packaging.

Technical Specifications

Four models designed to match your production requirements

| Parameter / Model | BTM-760P | BTM-950P | BTM-1100P | BTM-1400P |

|---|---|---|---|---|

| Paper specification 1st (W*L) | 760*760mm-100*150mm | 950*760mm-100*150mm | 1100*760mm-150*180mm | 1400*1400mm-150*180mm |

| Machine speed 1st | Up to 12,000 sheets/hour | Up to 12,000 sheets/hour | Up to 10,000 sheets/hour | Up to 9,000 sheets/hour |

| Paper specification 2st (W*L) | 760*420mm-100*150mm | 950*420mm-100*150mm | 1100*420mm-150*180mm | 1400*700mm-150*180mm |

| Machine speed 2st | Up to 24,000 sheets/hour | Up to 24,000 sheets/hour | Up to 20,000 sheets/hour | Up to 18,000 sheets/hour |

| Paper specification 3st (W*L) | 760*250mm-100*150mm | 950*250mm-100*150mm | 1100*450mm-150*180mm | 1400*450mm-150*180mm |

| Machine speed 3st | Up to 36,000 sheets/hour | Up to 36,000 sheets/hour | Up to 30,000 sheets/hour | Up to 27,000 sheets/hour |

| Window dimension (W*L) | 500*450mm-30*50mm | 500*450mm-30*50mm | 500*450mm-50*50mm | 700*700mm-60*50mm |

| Paper weight/sheet thickness | Cardboard: 200-2000g/m² Corrugated board: 1-4mm | |||

| Film thickness | PET: 0.03-0.2mm PVC: 0.03-0.25mm | |||

| Positioning accuracy | ±1 mm | |||

| Power voltage | 380V/50Hz | |||

| Machine power | 21KW | 21KW | 21KW | 24KW |

| Machine weight | 3000KG | 3300KG | 4000KG | 4500KG |

| Overall dimension (L*W*H) | 5500*1550*1800 mm | 5500*1750*1800 mm | 6300*1920*1800 mm | 6220*2300*1846 mm |

Need a tailored specifications? Contact our sales engineers for custom configuration and site requirements.

Components

Paper Feeding System

- Optimally stable separation blades with zero wobble

- Single-plate feeding belt simplifies mainienance

- Linear bearings for smooth paperpressing movement

- Pneumatic vibration motors reduce noise

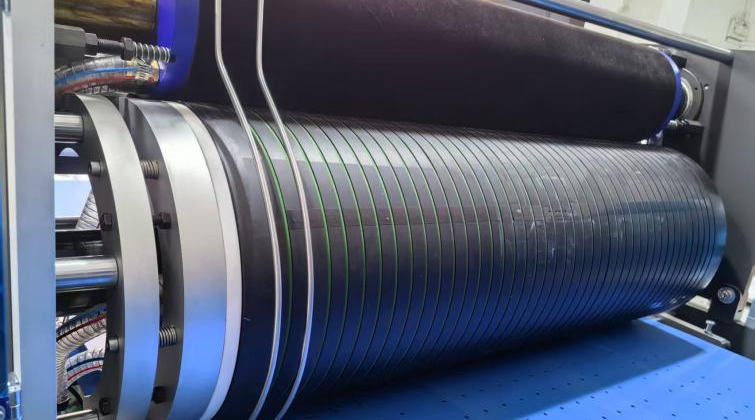

Film Lamination & Cutting System

- Monolithic roller ensures stability

- Aluminum alloy wear-resistant air grooves

- Spring + screw mechanism for zeropressure contact

- 180mm diameter cutting shaft withprecision air holes

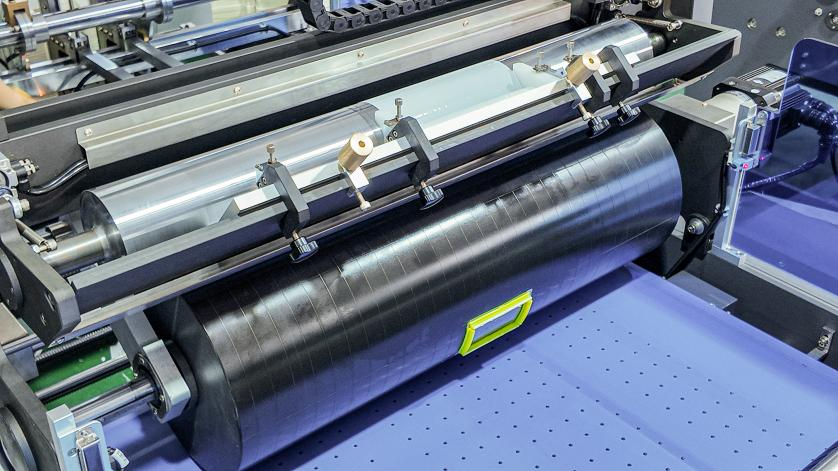

Paper Pressing Wheel Assembly

- Gear-driven dual-power transmission onupper/lower wheels delivers exceptionalstability during paper conveyance,particularly with corrugated paper.

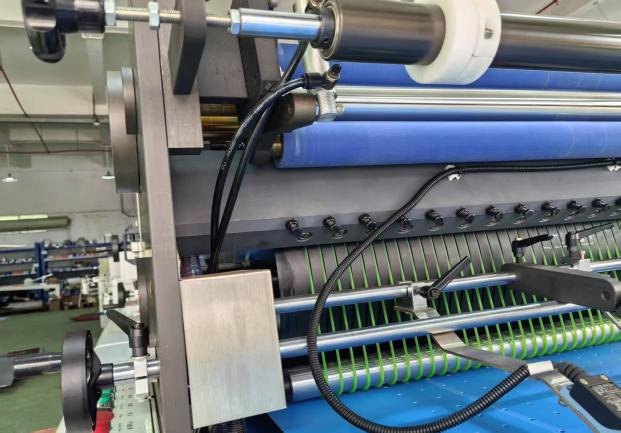

Bottom Blade & Film Feeding

- Bottom Blade: Reinforced casting; V-shaped structure (spiral blade-inspired);5mm sharp steel blade; detachablestainless steel bridge + felt prevent filmscratching

- Film Feeding: Dual rollers + long-armpneumatic clamping for precise length control.

Pusher Claw System

- Linear guide fixation eliminates vibration(vs. linear bearings),ensuring stable paperfeed.

- Patent-certified synchronous belt driveprovides quiet operation, stretchresistance, oil-free performance, lownoise, and sustained precision.

- Front/rear adjustable press wheels adaptto product positions; side-fixed designsimplifies setup. Side guides synchronizewith claws to reduce adjustmentfrequency and time.

Innovative Tissue Box Slotting Unit

- Optimally stable separation blades with zero wobble

- Single-plate feeding belt simplifies mainienance

- Linear bearings for smooth paperpressing movement

- Pneumatic vibration motors reduce noise

Gluing System

- Independent servo drive with HMlparameter control

- Hard-anodized aluminum alloy glue rollers

- Glue sensor for automatic activation

- Jam detection with alarm/shutdownfunction

Film Unwinding & Collection System

- Unwinding Unit: Dual frames support dualwindow patching; single-side fixation +operable-side access; magnetic particlebrake; axial film sensor requires norecalibration.

- Collection Unit: Independent servo systemwith integrated counting function,Configurable sheet quantity and stackingintervals.

Glue Distribution System

- Dedicated servo drive simplifestransmission and maintenance.

- Collection Unit: independent servo systemwith integrated counting function;Configurable sheet quantity and stackingintervals.

Electrical System

- INOVANCE components (China's top-tierbrand)

- Bus-based control for efficient operation

- Stable performance with simplifed maintenance

- Smart diagnostics and monitoring

Why partner with Fengchi?

High Quality

Fengchi products are manufactured by a team of skilled and qualified technicians. Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Innovative Solutions

We work with you to find not just one, but the right solution for your packaging production – from stand-alone to turnkey.

Global Support

With three offices around the world, and around 50 agents, we are able to provide local support on a global level.

Trusted by Industry Leaders Worldwide

John Doe

Production Manager

Chicago, USA

Maria Schmidt

Operations Director

Hamburg, Germany

Thomas Wilson

Plant Manager

Manchester, UK

Our Service for Your Success

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines.

Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

Frequently Asked Questions

What is the maximum speed of Model P window patcher?

Model P window patcher can reach up to 36,000 sheets/hour, with stable continuous production around 32,000 sheets/hour.

Which products fit Model P window patcher?

It’s designed mainly for tissue boxes and other flat windowed cartons that require accurate, high-speed film patching, including cosmetic boxes, electronic product boxes, cake boxes, toy boxes, and various retail packaging.

What's the delivery time?

Typical lead time is 10–30 working days after order confirmation. The specific delivery time depends on the product and the order quantity.

Can it integrate with my folder gluer line?

Yes, Model P window patcher connects easily to most folder gluers or post-press conveyors for streamlined packaging automation.

How about warranty?

Warranty period: 12 months from the shipping date of machine. Warranty will be not valid if machine subject to misuse or accidental damage or operator’s error. During the valid time, we will supply spare parts. If you have any other questions, pls contact us and we will reply you through product’s photos and videos to make every detail clear. We also provide all lifetime warranty with paid service.

How about installation and training?

Normally, one operator can finish intallation in 2 hours with installation manual and video. If purchaser’s engineer travels at own cost to China, free training session. If engineer sent to purchaser’s factory, all travel cost paid by purchaser.

Will you supply for OEM orders?

Yes, we can customize the production machine according to your requirements.

Get in Touch

Contact our engineering team today to discuss your requirements, request a quote, or schedule a live demo.