Model Y Window Patcher

Precision engineering meets production efficiency.

High throughput — up to 36,000 sheets/hr. Precision accuracy — ±0.5mm.

Model Y Window Patcher

Precision engineering meets production efficiency.

Key Features & Benefits

The Model Y Window Patching Machine features a flat patching system and registration system, enabling efficient handling of various window operations on folding cartons.

High-Speed Efficiency

Maximum flat patching speed of 36,000 sheets/hr and an alignment speed of 15,000 sheets per/hr

Intelligent Collection

Automatic count & stack collection for non-box products with configurable sheet quantity and stacking intervals.

Precision Control

Full-servo system with ±1.0mm flat-patching and ±0.5mm registration accuracy for perfect alignment every time.

Intelligent Setup

Digital settings with one-touch control for glue, film, and cutting parameters. No whistles or phase adjustment needed.

Long-Term Durability

35% load-reserve servos and >15 year lifespan with minimal maintenance requirements.

Gentle Film Feeding

Independent servo control ensures smooth feeding without stretching or damaging materials.

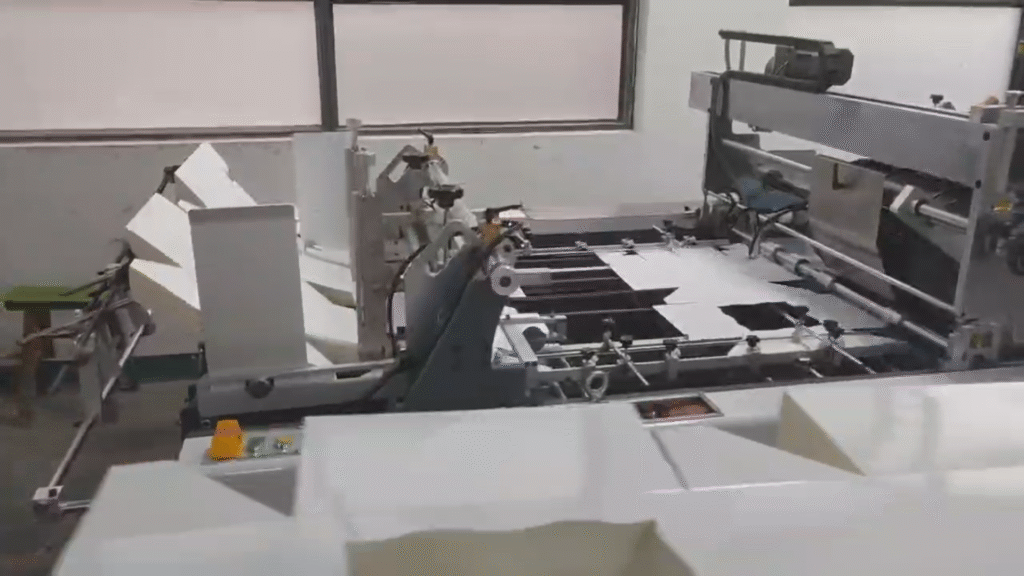

See Model Y Window Patcher in Action

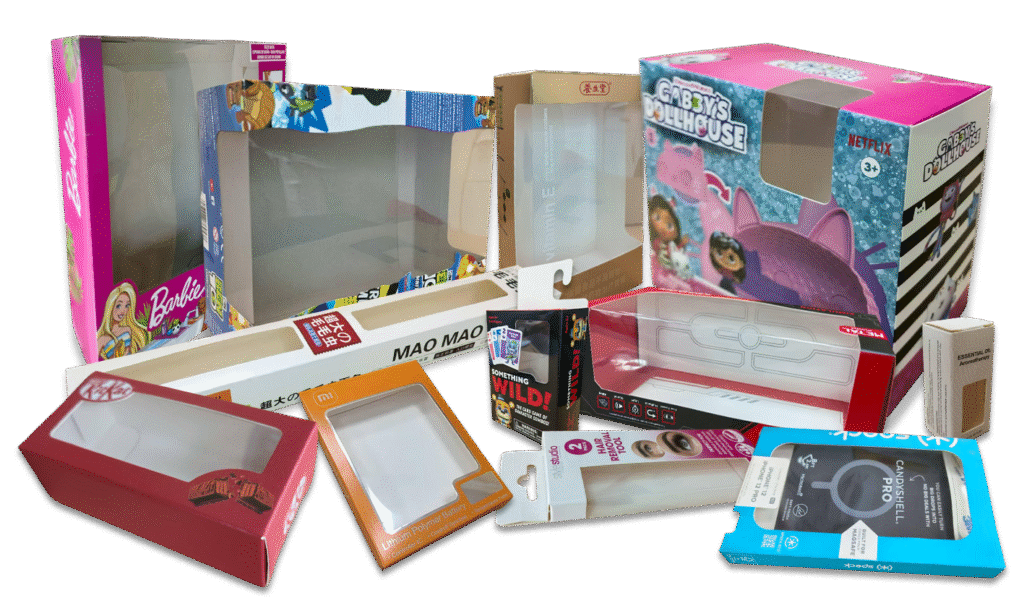

Final Product Samples

Technical Specifications

Available in three configurations to match your production requirements

| Model | BTM-760Y | BTM-950Y | BTM-1100Y | |

|---|---|---|---|---|

| Flat Patching section | Paper specification 1st (W×L) | 760×760mm-100×150mm | 950×760mm-100×150mm | 1100×760mm-150×180mm |

| Machine speed 1st (W×L) | Up to 12,000 sheets/hr 0~760mm | Up to 12,000 sheets/hr 0~760mm | Up to 10,000 sheets/hr 0~760mm | |

| Paper specification 2st (W×L) | 760×420mm-100×150mm | 950×420mm-100×150mm | 1100×420mm-150×180mm | |

| Machine speed 2st (W×L) | Up to 24,000 sheets/hr 0~420mm | Up to 24,000 sheets/hr 0~420mm | Up to 20,000 sheets/hr 0~420mm | |

| Paper specification 3st (W×L) | 760×260mm-100×150mm | 950×260mm-100×150mm | 1100×260mm-150×180mm | |

| Machine speed 3st (W×L) | Up to 36,000 sheets/hr 0~260mm | Up to 36,000 sheets/hr 0~260mm | Up to 30,000 sheets/hr 0~260mm | |

| Window dimension (W×L) | 500×450mm-30×50mm | 500×450mm-30×50mm | 500×450mm-50×50mm | |

| Positioning accuracy | ±1mm | ±1mm | ±1mm | |

| Registration section | Paper specification 1st (W×L) | 760×760mm-100×150mm | 950×450mm-100×150mm | 1100×760mm-150×180mm |

| Machine speed 1st (W×L) | Up to 15,000 sheets/hr 0~760mm | Up to 15,000 sheets/hr 0~760mm | Up to 15,000 sheets/hr 0~760mm | |

| Paper specification 2st (W×L) | 760×420mm-100×150mm | 950×420mm-100×150mm | 1100×420mm-150×180mm | |

| Machine speed 2st (W×L) | Up to 15,000 sheets/hr 0~420mm | Up to 15,000 sheets/hr 0~420mm | Up to 15,000 sheets/hr 0~420mm | |

| Window dimension (W×L) | 500×400mm-30×50mm | 500×400mm-30×50mm | 500×400mm-50×50mm | |

| Positioning accuracy | ±0.5mm | ±0.5mm | ±0.5mm | |

| Paper weight/sheet thickness | Cardboard: 200–2000g/m² Corrugated board: 1–4mm | |||

| Film thickness | PET: 0.03–0.2 PVC: 0.03–0.25 | |||

| Power voltage | 380V/50Hz | |||

| Machine power | 28kW | |||

| Machine weight | 3200kg | 3500kg | 4200kg | |

| Overall dimension (L×W×H) | 5500×1600×2080mm | 5500×1850×2080mm | 5500×2000×2080mm | |

* Need a tailored spec? Contact our sales engineers for configuration and site requirements.

Components

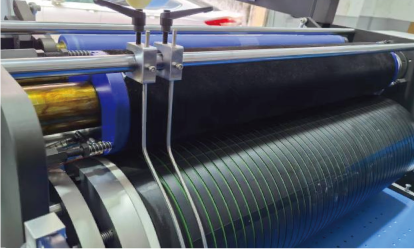

Paper Feeding System

- Features optimally stable separation blades with zero wobble when locked, ensuring superior paper separation.

- Single-plate feeding belt simplifies maintenance and replacement.

- Linear bearings enable smooth front/rear movement of the paper pressing mechanism; pneumatic vibration motors reduce noise and optimize vibration.

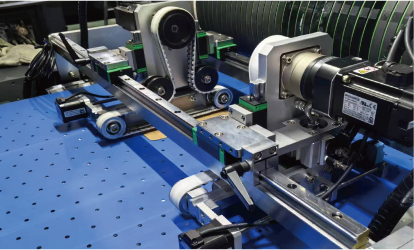

Paper Pressing Wheel Assembly

- Gear-driven dual-power transmission on upper/lower wheels delivers exceptional stability during paper conveyance, particularly with corrugated paper.

Paper Pressing Wheel Assembly

- Linear guide fixation eliminates vibration (vs. linear bearings), ensuring stable paper feed.

- Patent-certified synchronous belt drive provides quiet operation, stretch resistance, oil-free performance, low noise, and sustained precision.

- Front/rear adjustable press wheels adapt to product positions; side-fixed design simplifies setup. Side guides synchronize with claws to reduce adjustment frequency and time.

Gluing System

- Independent servo drive allows parameter input via HMI without wrenches or phase adjustment.

- Hard-anodized aluminum alloy glue rollers offer lightweight and high hardness.

- Optimized program with glue sensor enables automatic activation with product presence, separation without product, and jam alarm/shutdown.

Pusher Claw System

- Dedicated servo drive simplifies transmission and maintenance.

- Entire unit slides out for cleaning.

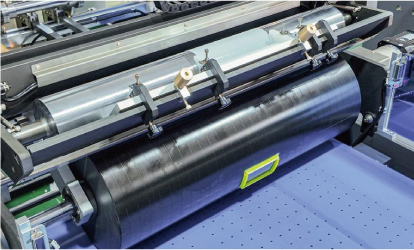

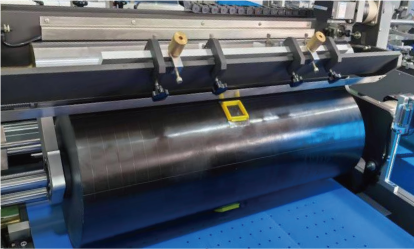

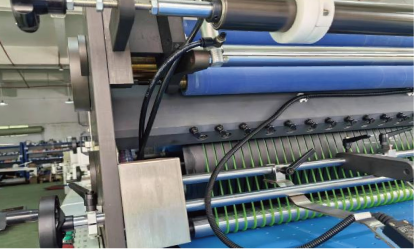

Film Lamination & Cutting System

- Lamination Unit: Monolithic roller ensures stability; aluminum alloy wear-resistant air grooves; spring + screw mechanism enables zero-pressure contact and tool-free maintenance.

- Cutting Shaft: 180mm diameter/40mm wall; 17 deep holes + hundreds of air holes with end grooves ensure smooth cutting.

Bottom Blade & Film Feeding

- Bottom Blade: Reinforced casting; V-shaped structure (spiral blade-inspired); 5mm sharp steel blade; detachable stainless steel bridge + felt prevent film scratching.

- Film Feeding: Dual rollers + long-arm pneumatic clamping for precise length control.

- Glue sensor for automatic activation

- Jam detection with alarm/shutdownfunction

Film Unwinding & Collection System

- Unwinding Unit: Dual frames support dualwindow patching; single-side fixation +operable-side access; magnetic particlebrake; axial film sensor requires no recalibration.

- Collection Unit: Independent servo systemwith integrated counting function,Configurable sheet quantity and stacking intervals.

Innovative Tissue Box Slotting Unit

- Independent servo drive enables digital position adjustment.

- Manual screw fine-tuning for lateral positioning.

- Surgical blades allow easy replacement.

Secondary Positioning System

- Utilizes secondary positioning technology to effectively eliminate errors from push claws entering the belt and glue spreading drive, enhancing overall positioning accuracy.

Register Film Production System

- A modular register film production system integrates servo intelligent film feeding, long-distance film swinging, servo braking, and two-verti- cal-one-horizontal corner cutting and creasing functions, achieving high-precision intelligent film production.

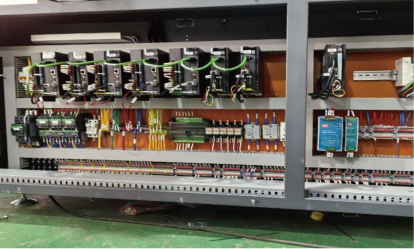

Electrical System

- INOVANCE components (China’s top-tier brand) with bus-based control ensure efficient, stable operation and simplified maintenance.

Why Partner with Fengchi

High Quality

Fengchi products are manufactured by a team of skilled and qualified technicians. Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Innovative Solutions

We work with you to find not just one, but the right solution for your packaging production – from stand-alone to turnkey.

Global Support

With three offices around the world, and around 30 agents, we are able to provide local support on a global level.

Trusted by Industry Leaders Worldwide

“Since integrating the MODEL Y into our production line, we’ve shattered our previous output records. The claim of 36,000 sheets per hour isn’t just a number on a brochure—it’s our new reality. The ability to run continuously at high speed for 24-hour shifts has been a game-changer for meeting our large-volume orders without compromising on deadlines. This machine is the backbone of our productivity.”

– Sophie Laurent, Production Manager.

Our Service for Your Success

Fengchi Printing Machinery knows that successful installation, training, and support are critical to your operation and achieving the profitability gains you target. This drives our commitment to your success.

Our goal is to provide you with the tools and technical knowledge that your in-house maintenance needs, to be able to fix their own machines.

Our technical support team and parts department work with customers to resolve issues over the phone, but when special care is needed, our team is prepared to make emergency field service visits, to get your plant up and running quickly. Parts, service, and support are handled directly through the Fengchi technical support group.

Tell Us About Your Project

By filling in your information, we will provide you with a personalized quote.