Overview

In the second week of 2026, ONEZIM’s after-sales engineering team traveled to the United States to install and commission a custom QTM-1100P high-speed automatic integrated window patching machine for a key client. Engineered for high throughput and precision, the QTM-1100P delivered both the speed and patching quality the customer required. This article summarizes the installation, key technical features, measurable outcomes, and business benefits — written to support discoverability and buyer decision-making.

Installation & trial production — U.S. case study

ONEZIM’s engineers completed on-site installation, commissioning, and trial production at the client’s manufacturing facility. The machine’s dual-channel design enabled the client to switch quickly between flat patching and alignment modes, maximizing flexibility for mixed production runs. During commissioning, both patch quality and operating speed matched the client’s specifications, and the engineering team received immediate positive feedback for their technical expertise and thorough handover.

Key measurable outcomes from the site visit:

- Successful installation and full commissioning completed within the scheduled service window.

- Trial production demonstrated continuous high-speed operation that met client expectations.

- Client satisfaction was high for both machine performance and the quality of after-sales support.

Technical highlights — QTM-1100P

The QTM-1100P is designed for printers and converters that require continuous, precise, and high-volume window patching. Notable features include:

- High-Speed Efficiency

Max speed: 36,000 sheets/hr (200 m/min); continuous operation at 32,000 sheets/hr (185 m/min) for 24/7 production. - Intelligent Sheet Collection

Automatic counting and stack collection for non-box products to streamline downstream handling. - Precision Control

Full-servo control system delivering ±1.0 mm flat-patching accuracy and ±0.5 mm registration accuracy, even at top speeds. - Long-Term Durability

Equipment designed with 35% load-reserve servos and a projected service life exceeding 15 years. - Intelligent Setup

Digital settings plus one-touch adjustments for glue, film, and cut parameters reduce setup time and operator error. - Synergistic Drive

Nine independent servos for coordinated motion control and operational intelligence. - Precision Alignment

Design eliminates push-claw and glue-drive errors to ensure consistent positioning and fewer rejects. - Gentle Film Feeding

Independent servo control for film feed that prevents stretching and maintains film integrity.

Business benefits

- Increased throughput: High continuous speeds enable significant output increases for high-volume lines.

- Lower waste / higher yield: Precision registration and alignment reduce misfeeds and rework.

- Reduced labor and setup time: Digital one-touch setups make changeovers faster and less error-prone.

- Reliability and uptime: Durable components and reserve capacity reduce maintenance frequency and extend lifecycle value.

- Versatility: Dual-channel mode offers flexibility for mixed product runs without requiring additional machines.

Recommended use cases

- Window patching for retail packaging, presentation boxes, and consumer goods cartons.

- High-volume litho-laminated or printed sheet manufacturing where registration accuracy is critical.

- Production environments that require 24/7 continuous runs with minimal operator intervention.

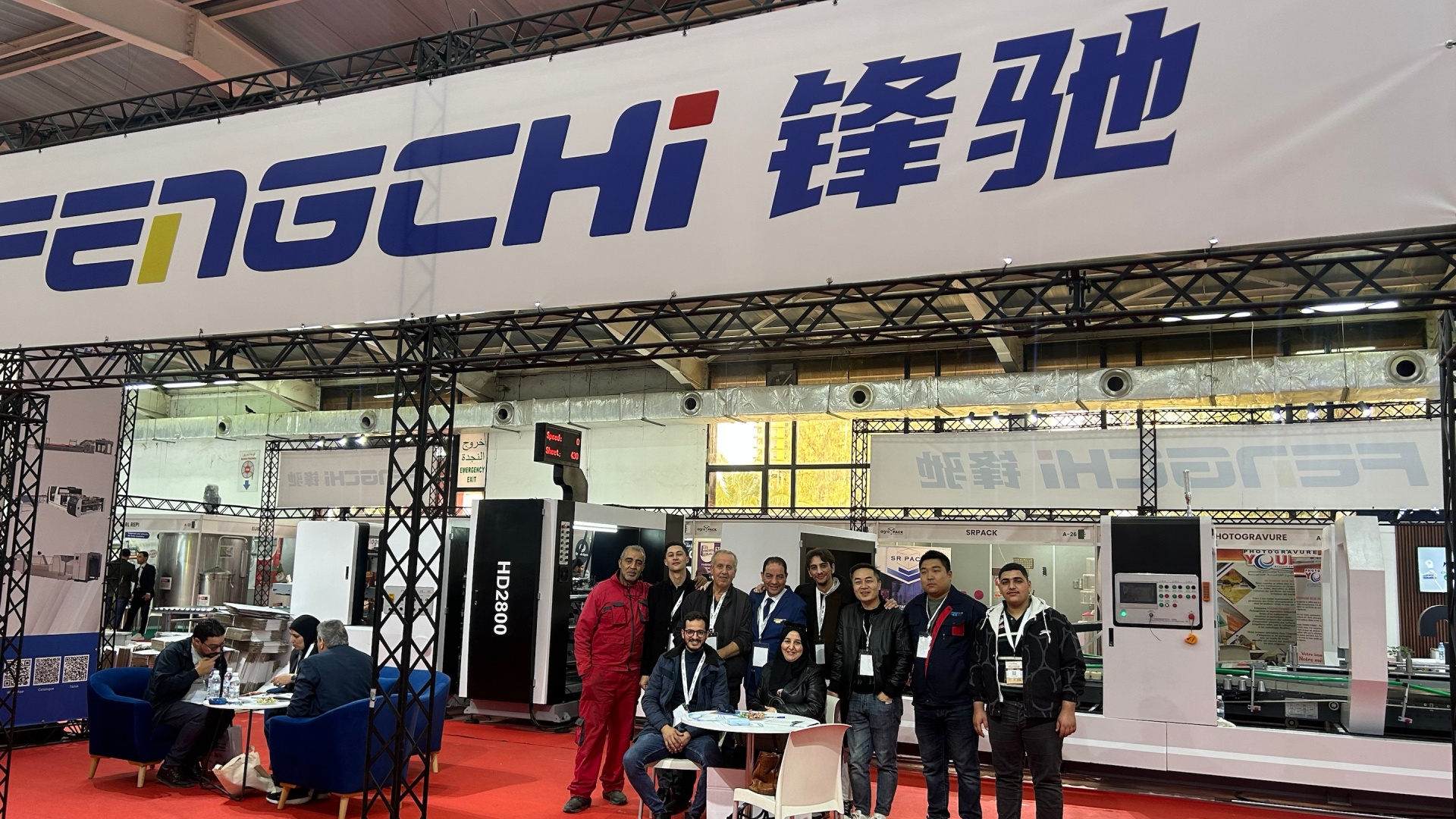

About ONEZIM & FENGCHI partnership

ONEZIM operates as a sub-brand of FENGCHI, leveraging FENGCHI’s established supply chain and manufacturing standards used for flute laminators and other post-press equipment. The ONEZIM portfolio now includes automatic folding and gluing machines, folding and gluing stitching systems, high-speed spot UV coaters, and window patchers such as the QTM-1100P. ONEZIM combines product breadth with field service capabilities to deliver turnkey solutions and long-term technical support.

Frequently asked questions

Q: What throughput can the QTM-1100P sustain continuously?

A: The QTM-1100P is rated for continuous operation at 32,000 sheets/hr (185 m/min) and can reach 36,000 sheets/hr (200 m/min) for short bursts.

Q: How accurate is the QTM-1100P for registration?

A: Registration accuracy is ±0.5 mm, with flat-patching tolerance of ±1.0 mm under full-speed operation.

Q: Does ONEZIM provide on-site commissioning in the U.S.?

A: YES. ONEZIM’s experienced after-sales engineers completed a full installation, commissioning, and trial production in the United States during early 2026, and the team provides similar support globally.

Q: Is the machine suitable for 24/7 production?

A: Yes. The QTM-1100P is engineered for continuous 24-hour operation and uses components sized with margin (35% load-reserve servos) to support long-term reliability.

Q: Can the QTM-1100P handle different formats without lengthy changeovers?

A: Yes. Digital settings and one-touch adjustments for glue, film, and cut parameters reduce setup time and simplify changeovers.

ONEZIM engineers install and commission the QTM-1100P in the United States. Read the technical specifications, performance results, and benefits of this dual-channel, full-servo window patcher.