In today’s competitive packaging landscape, combining eye‑catching graphics with robust durability is essential. A litho laminator delivers just that: it bonds pre‑printed paper to corrugated cardboard, resulting in packaging that stands out on the shelf and endures handling, shipping, and storage.

How a Litho Laminator Transforms Corrugated Cardboard

What Is a Litho Laminator?

A litho laminator is a specialized post‑press machine designed to accurately laminate pre‑printed lithographic sheets onto corrugated board. Unlike traditional cold‑glue methods, litho laminators provide:

- Precision alignment of printed sheets

- Consistent adhesive application to flute tips

- High‑speed operation for large‑volume production

By uniting print and substrate in a single process, litho lamination creates premium packaging solutions that meet both aesthetic and functional demands.

Key Components of a Litho Laminator

Every litho laminator comprises three main sections, each vital to seamless production:

1. Feeding Section

This module handles the pre‑printed paper sheets, ensuring they’re correctly separated and aligned before lamination. Key features include:

- Suction or mechanical sheet feeders

- Registration guides for precise placement

2. Laminating Section

Here, adhesive is applied to the flute tips of the corrugated carrier, and the printed top paper is pressed onto the board. Components include:

- Gluing unit: Dispenses adhesive exactly where needed

- Pressure rollers: Ensure uniform bond strength

- Alignment system: Keeps paper and board perfectly registered

3. Delivery Section

Once bonded, the finished boards are stacked or conveyed for downstream processes. High‑capacity stackers and conveyors maximize throughput and minimize manual handling.

Benefits of Litho Lamination

Superior Print Quality

Litho lamination preserves the vividness and resolution of lithographic printing, producing sharp, vibrant graphics that elevate brand perception.

Enhanced Durability

By bonding paper directly to the corrugated medium, laminated packaging resists tearing, moisture, and abrasion—ideal for food, electronics, and household chemicals.

Eco‑Friendly and Recyclable

Modern litho laminators use water‑based adhesives compatible with recycling streams. Laminated boxes can be easily repulped and reused, aligning with sustainability goals.

Industry Applications

Laminated corrugated packaging is popular across multiple sectors:

- Food & Beverage: Attractive, durable boxes for cereals, snacks, and take‑out packaging

- Electronics: Protective, high‑impact packaging for devices and components

- Household Chemicals: Moisture‑ and puncture‑resistant containers

- Publishing & Retail: Premium gift boxes, point‑of‑sale displays, and promotional materials

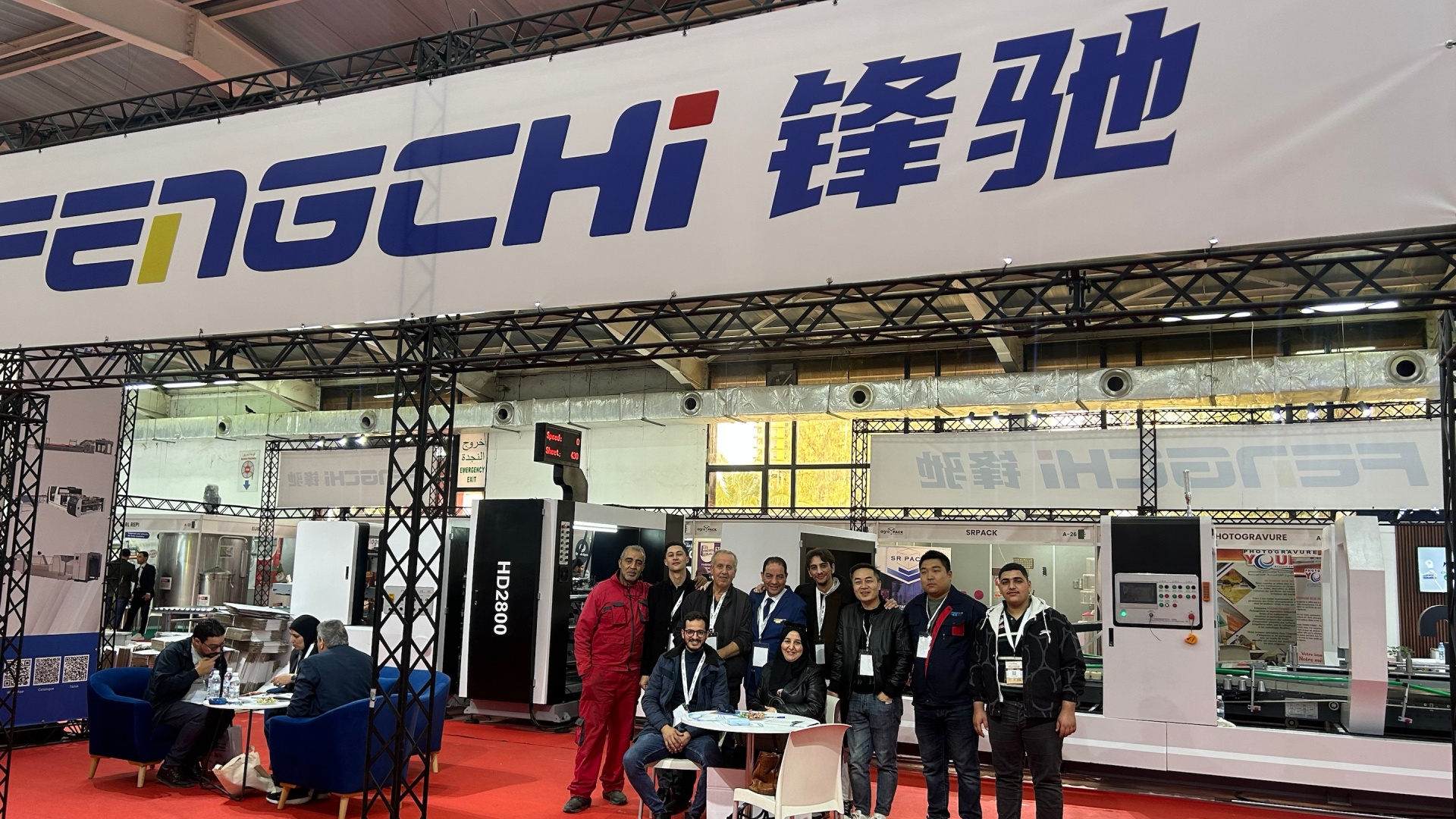

Why Choose Fengchi’s Full‑Servo Litho Laminators?

As China’s leading provider of automatic litho laminators, Fengchi offers turnkey solutions tailored to corrugated and folding carton producers worldwide:

- High‑Speed Performance:

- Steady‑state speeds of 16,000 sheets/hour

- Max speeds up to 22,000 sheets/hour

- Full‑Servo Control: Precision motion for consistency and reduced waste

- Flip‑Stacker Technology: Automated stacking for seamless integration with finishing lines

- Global Track Record: Over 2,600 projects completed in 50+ countries

Fengchi’s expert team supports you from machine selection to installation, training, and ongoing maintenance—ensuring peak productivity and minimal downtime.

Maximizing ROI with Expert Support

Investing in a litho laminator is more than hardware; it’s a commitment to efficiency and quality. Fengchi offers:

- Comprehensive Training: Empower operators with in‑depth machine knowledge

- Responsive Service: Minimize production interruptions with fast parts and technical support

- Tailored Solutions: Customize machine configurations to match your product mix and volume

Become a Fengchi Agent

Fengchi is expanding its global network and invites experienced, customer‑focused agents to join us. Benefits include:

- Access to industry‑leading litho laminator technology

- Dedicated sales and technical support

- Competitive agent margins and marketing resources

Interested? Contact our sales team today to explore partnership opportunities and bring Fengchi’s advanced flute laminating solutions to your market.

Conclusion

A litho laminator is the cornerstone of premium corrugated packaging, delivering unmatched print fidelity, durability, and sustainability. Whether you produce food boxes, electronics packaging, or retail displays, Fengchi’s high‑speed, servo‑driven machines and world‑class support ensure you stay ahead of market demands. Enhance your packaging line—invest in litho lamination and reap the benefits of superior quality and performance.

Discover how a litho laminator enhances print quality and durability for corrugated cardboard packaging. Learn about its key components, benefits, and why Fengchi’s high‑speed laminating solutions lead the industry. We are expanding our global network and invites experienced, customer‑focused agents to join us.