Post-Press Machines

Automatic flute laminators, folder gluers, folder gluer stitchers, spot UV coating machines, and

window patchers engineered for high-speed, high-accuracy and fast changeovers.

Three Core Challenges Facing Packaging Manufacturers

Efficiency Bottleneck

Long changeover times hinder the ability to handle small-batch, multi-variety e-commerce orders.

Quality Loss

Inaccurate mechanical alignment leads to high scrap rates, damaging brand consistency and profit margins.

Talent Gap

High reliance on skilled labor amidst rising costs and recruitment difficulties makes automation a necessity.

Our Proven Automation Solutions

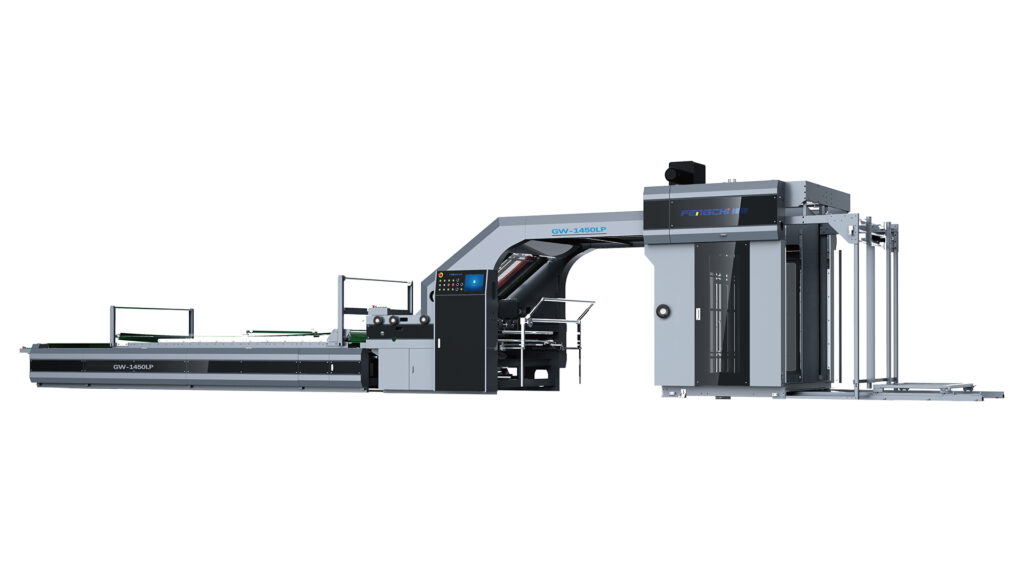

High speed flute laminator

High-speed flute laminator for corrugated packaging manufacturers.

The fully digital operating system automatically adjusts machine

Maximum lamination speed of 22,000 sheets/hour, stable high speed of 16,000 sheets/hour

Increased roller diameter as 150mm, double bearing with auto refueling system, maintenance-free

Front paper feeder suitable for all kinds of deformed, warped corrugated paper or paperboard.

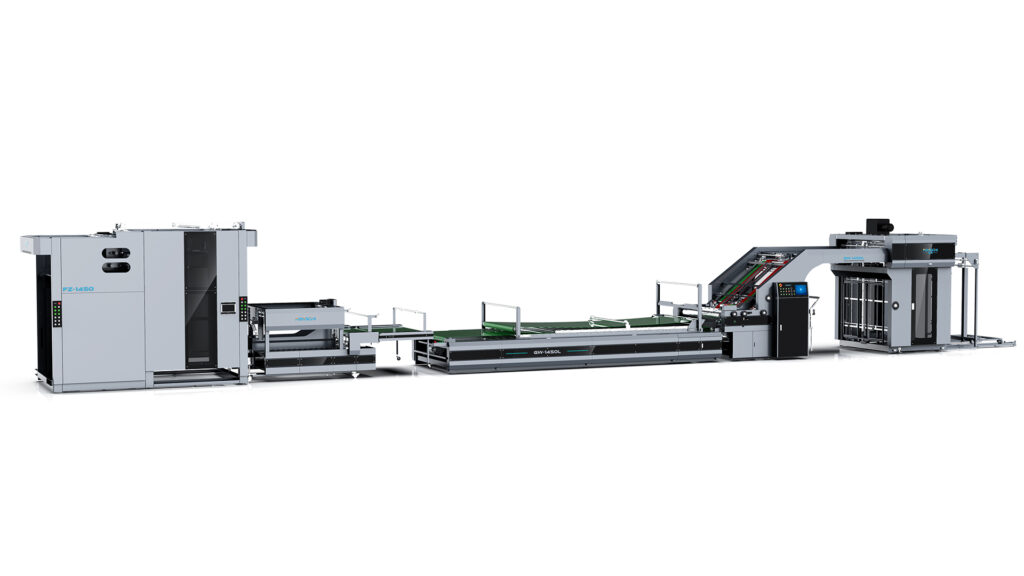

Automatic flute laminating line

Automatic flute laminating line for corrugated packaging manufacturers.

The fully digital operating system automatically adjusts machine

Maximum lamination speed of 22,000 sheets/hour, stable speed of 16,000 sheets/hour

Increased roller diameter as 150mm, double bearing with auto refueling system, maintenance-free

Front paper feeder suitable for all kinds of deformed, warped corrugated paper or paperboard.

Automatic folder gluer

Fully automatic folder gluer machine for folding carton production

Strong Stability — independently controlled dual suction and feeding mechanism to ensure the operation stable, reliable and high accuracy.

High Speed — maximum AB sheet gluing speed over 2,500 sheets/hour.

High Accuracy — motion control servo position system to ensure the high precision on the alignment and automatic digital adjustment.

Strong Cohesiveness — hot melt adhesive for instant sticking location, and cold glue for cement.

Full Digital Automation — servo motors control for key parameter adjustments and one-key operation.

Automatic folder gluer stitcher

Fully automatic folder gluer stitcher for corrugated box production

High Productivity: Speed Up to 1600 Stitches/Min

Single and double stitching modes with one-click switching.

Energy-saving swing head for faster, more stable stitching and improved box quality.

Versatility: Handle a wide range of carton sizes and materials.

Automatic Spot UV coating machine

Automatic spot UV coating is a cost-effective technique that adds shine and sophistication to any print product.

High Productivity: Speed Up to 8000 Sheets Per Hour

Coating Registration Accuracy: ±0.15mm

Coating Layer Thickness: 0.15mm ~0.60mm

Full Automation: One-Key Operation

- Quick Setup: 2-3 Minutes

Automatic window patcher

Fully automatic window patching machine for cardboard packaging

High-Speed Efficiency:Max speed 36,000 sheets/hr (200m/min); continuous 32,000 sheets/hr (185m/min), 24h non-stop.

Intelligent Sheet Collection:Auto count & stack collection for non-box products.

Precision Control:±1.0 mm film accuracy. (full-servo bus + proprietary tech)

Long-Term Durability:35% load‑reserve servos; > 15 year life span.

Intelligent Setup:Digital settings + one-touch for glue, film, cut.

Synergistic Drive:9 servos for smart operation.

Case Study: From Trial to Transformation

See how our machinery delivers measurable ROI and operational improvements for packaging manufacturers worldwide.

Mr. Li's Packaging Factory: 1 Machine → 10 Machine Fleet

When a modern packaging factory tests a single machine and then quickly expands to an entire fleet, that’s a signal worth paying attention to. This is the story of Mr. Li — a young entrepreneur whose Shantou-based color printing and packaging operation tried one Fengchi GW-1450L high-speed flute laminator, saw immediate results, and ordered ten more.

The results highlight the core advantages of efficient post-press equipment: higher throughput, lower per-unit cost, operator satisfaction, and long-term trust in supplier support. After seeing a 40% increase in laminating capacity and a 60% reduction in finishing bottlenecks, Mr. Li’s decision to invest in 10 additional units was driven by clear ROI calculations.

Why Partner with Fengchi?

High Quality

Fengchi products are manufactured by a team of skilled and qualified technicians. Our quality management system is certified by ISO9001. Products manufactured by Fengchi are also certified by CE.

Innovative Solutions

We work with you to find not just one, but the right solution for your packaging production – from stand-alone to turnkey.

Global Support

With three offices around the world, and around 50 agents, we are able to provide local support on a global level.

What Our Customers Say

See what our customers say about our post-press equipment.

We increased our corrugated board laminating throughput by 40% after installing the high-speed flute laminator. The support team was fantastic throughout the installation process.

– John Davidson, Production Manager

After trying three different brands, Fengchi equipment stands out for reliability. Minimal downtime and their service team responds immediately.

– Michael Torres, Operations Director

The window patching accuracy has eliminated our waste problems. We’re saving thousands annually on materials alone. Best investment we’ve made in years.

– Sarah Johnson, Owner

Trusted by Industry Leaders

Our Technical Service

After Sales service begins with the arrival of the machinery at the customer’s factory.

To maximize investment whether a single machine or an entire line, the equipment needs to enter the existing production quickly and deliver its contribution. Fengchi offers a dedicated team of technicians that assemble, calibrate and commission the machinery.

Our engineers teach customer operators the machines function, calibration, available options, best practice and scheduled housekeeping.

Fengchi is always available to its customers if they have a problem, concern or malfunctionwith their machinery.

Frequently Asked Questions

Are you a manufacturer?

Yes, we are post-press equipment from China over 15 years, specialize in automatic flute laminators, flip flop stackers, folder gluers, spot UV coating machines, and window patchers

Do you have stock products to sell?

We produce machines in bacth normally. So most models we have some in stock, please check with us before ordering.

How about warranty?

Warranty period: 12 months from the shipping date of machine. Warranty will be not valid if machine subject to misuse or accidental damage or operator’s error. During the valid time, we will supply spare parts. If you have any other questions, pls contact us and we will reply you through product’s photos and videos to make every detail clear. We also provide all lifetime warranty with paid service.

How about installation and training?

Normally, one operator can finish intallation in 2 hours with installation manual and video. If purchaser’s engineer travels at own cost to China, free training session. If engineer sent to purchaser’s factory, all travel cost paid by purchaser.

Do you test all your goods before delivery?

Yes, we have 100% functional testing and pilot run before delivery to ensure product integrity. All products are certificed by CE.

What is your delivery time?

Our delivery time is 10-30 working days after receiving full payment or deposit. The specific delivery time depends on the product and the order quantity.

What are your packaging conditions?

Usually, we pack the machine in a container with a plastic bag with desiccants, then with strong seaworthy wooden cases. Each machine will be protected by anti-rusted oil before put into case.

Will you supply for OEM orders?

Yes, we can customize the production machine according to your requirements.

Request a Quote

Discuss your project requirements with our experts—we’ll get back to you within 24 hours!