Automatic Window Patchers

We provide high-speed windowing patching solutions to folding carton producers worldwide,

helping reduce production costs, enhance efficiency, and strengthen competitive advantages.

Key Features & Benefits

Engineered for precision, built for durability, designed for your productivity

High Efficiency

Maximum flat patching speed of 36,000 sheets/hr and an alignment speed of 15,000 sheets per/hr.

Seamless Integration

Compatible with folder gluers and downstream lines for end-to-end packaging automation.

Precision Engineering

Experience flawless window patching with our precisely calibrated machines.

Intelligent Setup

Digital settings with one-touch control for glue, film, and cutting parameters. No whistles or phase adjustment needed.

Long-Term Durability

Built to last with high-quality materials for long-term reliability.

Expert Support

Comprehensive technical support and training for optimal operation.

Explore Our Products

Choose from our three premium automatic window patcher models, each designed for specific folding carton production requirements.

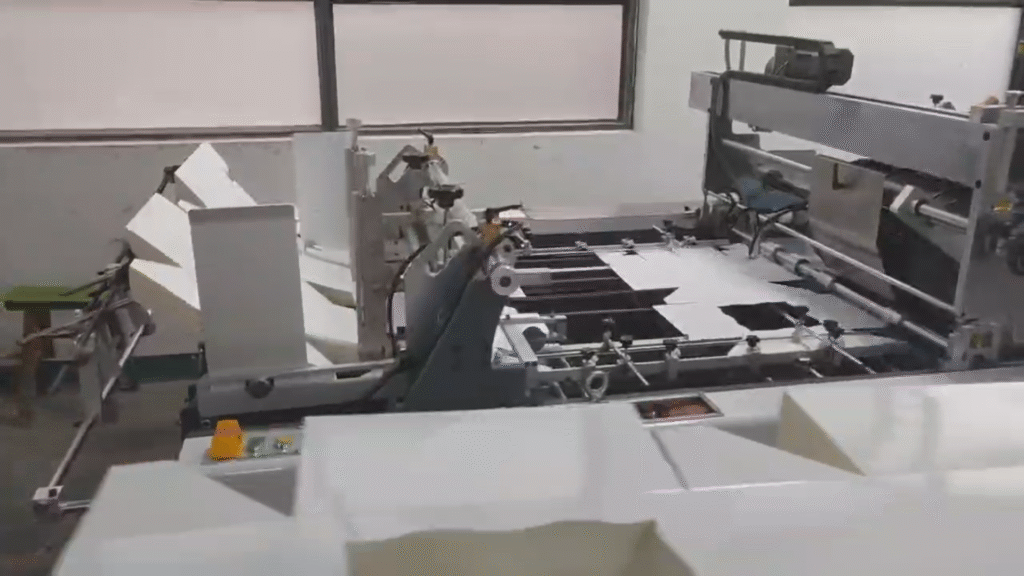

Model P

The Model P fully automatic window patching machine specifically designed for flat windows, particularly suitable for tissue boxes.

Recommendation: For tissue box flat window patching jobs requiring precision and maximum throughput.

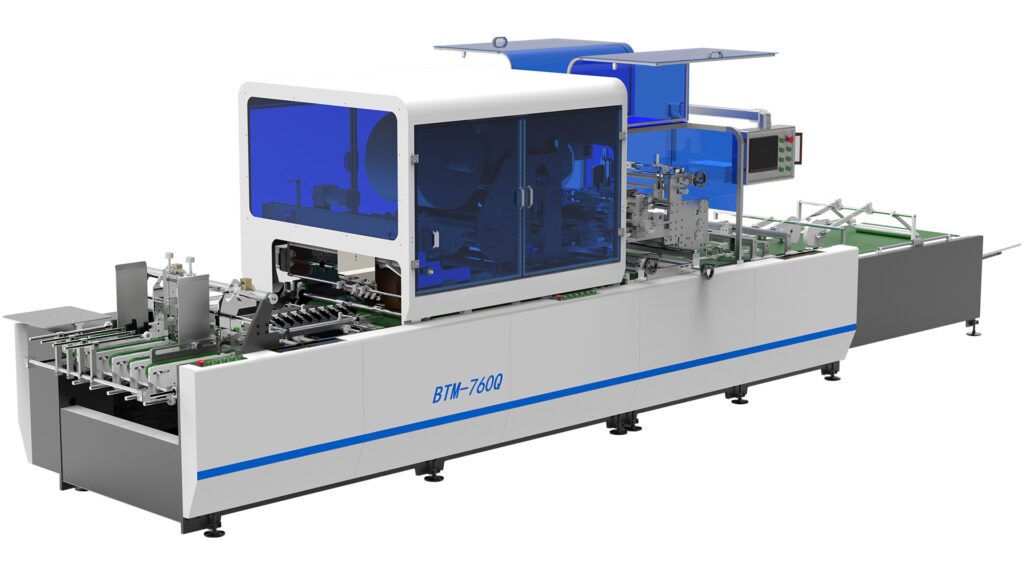

Model Q

The Model Q fully automatic window patching machine can complete corner cutting and creasing in one go, with high operational accuracy for various window patterns.

Recommendation: For window patching jobs requiring creasing, V cut cornering, and higher positioning accuracy.

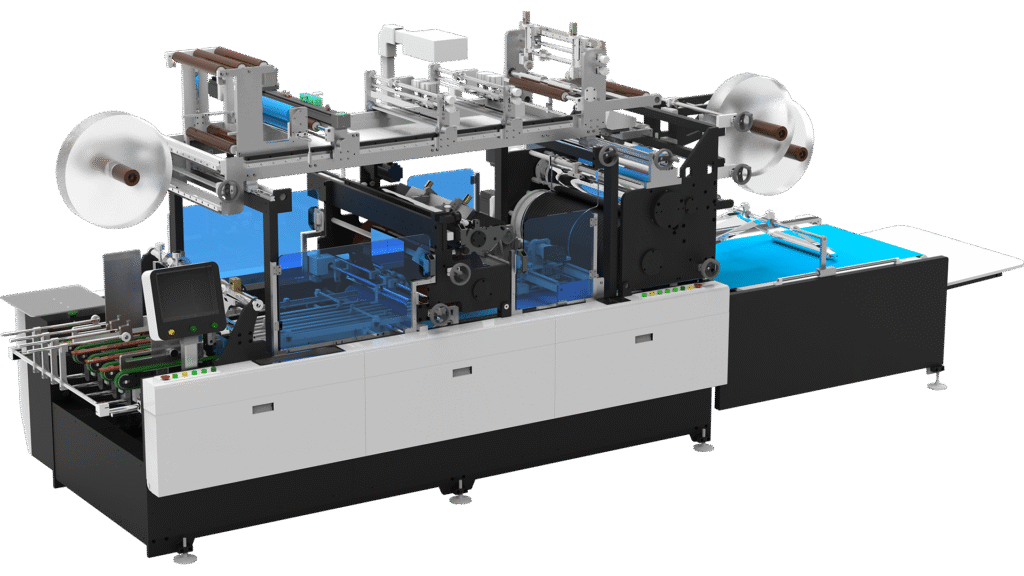

Model Y

The Model Y features both flat patching and registration systems, enabling efficient handling of various window operations on folding cartons.

Recommendation: For window patching jobs requiring both high efficiency in flat patching and better registration accuracy.

Applications

Versatile window patching solutions for diverse industries

Cosmetic Packaging

Premium beauty product boxes with precision windows

Electronics Packaging

Tech product boxes with professional finish

Cake & Bakery Boxes

Food-safe packaging with clear display windows

Tissue Boxes

Tissue paper box with window

Toy Packaging

Colorful retail boxes with product visibility

Why Partner with Fengchi?

15+ years of specialized experience in post-press machinery manufacturing

Proven Quality

Fengchi products are manufactured by skilled technicians with ISO9001 and CE certified quality management systems. Every machine undergoes rigorous testing before shipment.

Innovative Solutions

We work with you to find not just one, but the right solution for your packaging production – from stand-alone machines to complete turnkey production lines.

Global Support

With three offices worldwide and over 50 local agents, we provide responsive local support on a global level, including emergency field service visits when needed.

What Our Customers Say

Real feedback from packaging professionals worldwide

We run a high-mix schedule for cosmetics and toy boxes; this machine handles every window type we throw at it — thin films, reinforced patches, and tight registration jobs. The integrated registration capability guarantees die-cut alignment, which has significantly reduced rework and kept our line speed up. Robust build and great support made the integration seamless.

– Luca Moretti, Packaging Manager

The Model Q has completely changed our approach to quality control. We’ve reduced our scrap rate by over 90% and our technicians can now focus on more complex tasks. It paid for itself in just 10 months!

– Michael Torres, Production Manager

My team loves how safe and easy it is to use. The window patching accuracy has eliminated our waste problems. We’re saving thousands annually on materials alone. Best investment we’ve made in years.

– David Johnson, Owner

Trusted by Industry Leaders Worldwide

Our Technical Service

After Sales service begins with the arrival of the machinery at the customer’s factory.

To maximize investment whether a single machine or an entire line, the equipment needs to enter the existing production quickly and deliver its contribution. Fengchi offers a dedicated team of technicians that assemble, calibrate and commission the machinery.

Our engineers teach customer operators the machines function, calibration, available options, best practice and scheduled housekeeping.

Fengchi is always available to its customers if they have a problem, concern or malfunctionwith their machinery.

Request a Quote

Contact our experts to discuss your needs and find the perfect window patching solution for your business.