Automatic Folder Gluer Stitcher Machine

Boost your production with Fengchi’s automatic folder gluer stitcher machines. Designed for corrugated and folding carton manufacturers, our machines offer:

Fast setup & high speed: Reduce downtime and increase throughput.

Consistent adhesive application: Minimize waste and ensure strong bonds.

Versatility: Handle a wide range of carton sizes and materials.

Since 2009, Fengchi has led the industry in folding gluing and stitching technology, delivering reliable, high‑quality equipment built for maximum uptime.

Key Benefits

Precision stitching for durable cartons

Easy-to-use controls for quick format changes

Robust construction for long service life

Optimize your packaging line today.

Contact Fengchi to learn how our automatic folder gluer stitcher can elevate your manufacturing efficiency and capacity.

Automatic Folder Gluer Stitcher Machine – Key Features

Our automatic folder gluer stitcher combines folding, gluing, and stitching in one machine to improve efficiency and reduce labor costs. Key features include:

Full computer control for easy operation, fast speed, and stable performance.

Quick job change in just 3–5 minutes with order memory function for high-volume production.

Supports A/B/C/AB flute and 3-ply, 5-ply, 7-ply corrugated cardboard.

Automatic folding, gluing, stitching, correcting, counting, and stacking.

Single and double stitching modes with one-click switching.

Energy-saving swing head for faster, more stable stitching and improved box quality.

Paper correction system for accurate positioning and clean stitching.

Automatic stitch detection and break monitoring.

One-button switch between stitching and gluing modes.

This high-speed folder gluer stitcher is ideal for corrugated box manufacturers seeking automation, accuracy, and reduced setup time.

Automatic Folder Gluer Stitcher Machine Demo Video

Boost your box‑making efficiency with our Automatic Folder Gluer & Stitcher. Watch the demo video to see high‑speed, precision folding, gluing, and stitching for corrugated and folding cartons. Ready to automate large‑volume box production? Contact us today for specs, pricing, or a custom quote!

Automatic Folder Gluer Stitcher Machine Highlights

Feeding Part

With the retention frame pneumatic flap, more stable, higher accuracy.

Siegling high wear-resistance suction belt, can control the air volume, ensure complete paper adsorption, ensure stable paper transmission, accurate positioning.

Split air suction unit, effectively reduce the after-sales maintenance cost and time.

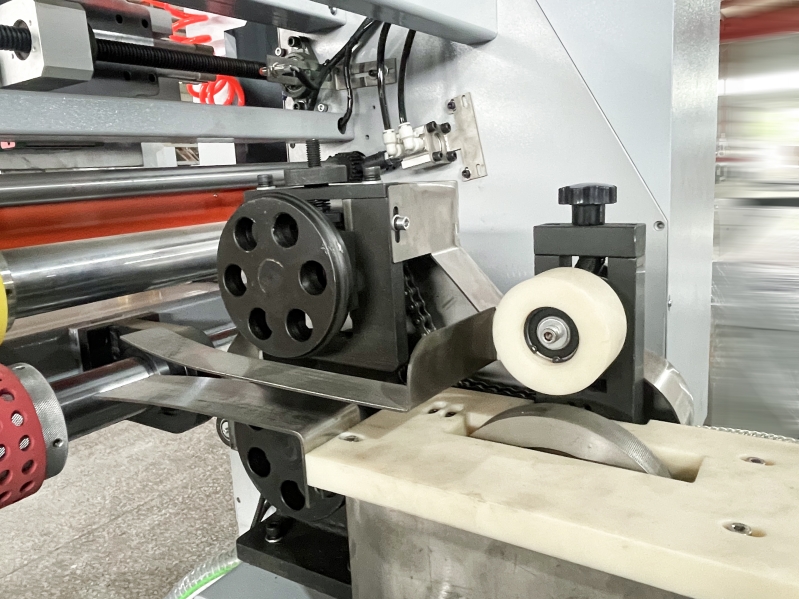

Pressing Part

The independent edge pressing structure effectively solves the problem of thick cardboard blasting in the process of stitching.

The split transmission shaft can be adjusted separately and tightened to ensure that the belt pressure is consistent, the paper is stable and effectively avoid the shaft phenomenon.

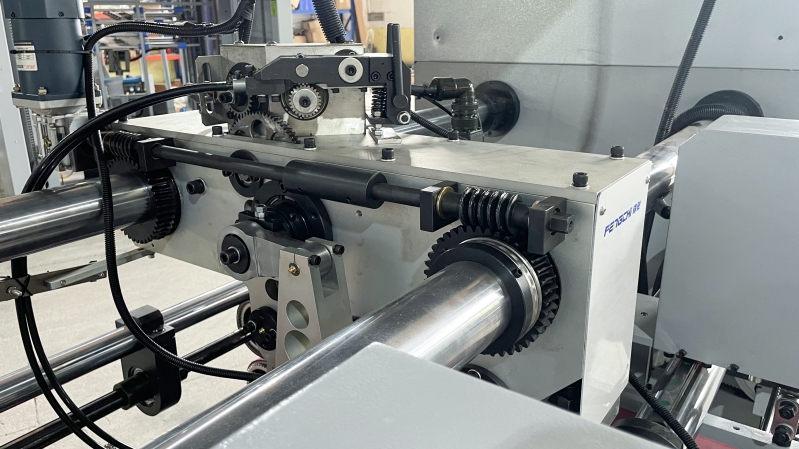

Creasing Part

motion control servo positioning system to ensure highly accurate on the alignment of carton gluing, and faster for digital adjustment.

Folding Part

Adopts synchronous belt drive to avoid the phenomenon of cold start skid and ensure the smooth transmission of paper.

Reinforced four-axis transmission to ensure that the machine operation, transportation process is stable, no deformation.

Flap Part

Reciprocating straight line beat correction, high accuracy, stable operation.

The forward-leaning arched beam is conducive for carton connection and transmission.

With the sunken belt, greatly strengthen the molding accuracy and smoothness of the carton.

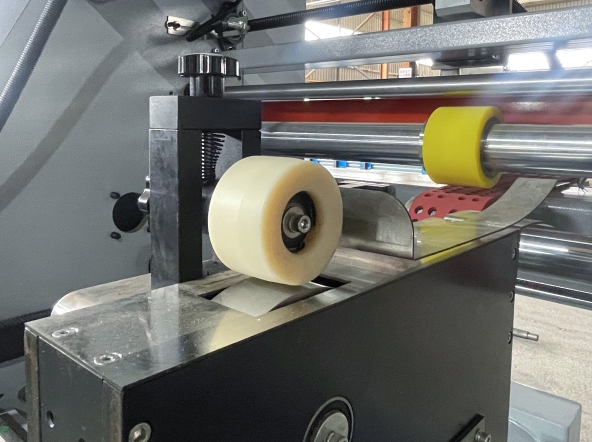

Stitching Part

The swing stitching head ensures low power consumption, faster speed, and greater stability, enhancing nail box quality.

Integrated design guarantees precise distance control, while simplifying installation, maintenance, and operation.

Technical Specifications

| Model | HD-2800 | HD-2800 Ultra | HD-3600 |

|---|---|---|---|

| Max sheet | Width 2800 mm × Length 1200mm | Width 2800 mm × Length 1200mm | Width 3600 mm × Length 1600mm |

| Min sheet | Width 830mm × Length 300mm | Width 760mm × Length 300mm | Width 1160mm × Length 400mm |

| Max stitching speed | 1600 stitches/min | 1600 stitches/min | 1600 stitches/min |

| Stitching gap | 40–500mm | 40–500mm | 40–500mm |

| Stitching quantity | 1–99 | 1–99 | 1–99 |

| Machine net weight | 9.7T | 11T | 12T |

| Machine size | L17000mm × W4100mm × H2200mm | L17000mm × W4100mm × H2300mm | L19000mm × W4400mm × H2800mm |

| Stitch angle | 45° | 45° | 45° |

| Air source | 0.6–0.8Mpa | 0.6–0.8Mpa | 0.6–0.8Mpa |

| Power source | 380VAC/3P, 50Hz | 380VAC/3P, 50Hz | 380VAC/3P, 50Hz |

| Power | ≤ 23 KW | ≤ 28 KW | ≤ 31 KW |

| Applicable paper | A, B, C, AB flute, 3ply, 5ply, 7ply corrugated paper | ||

| Automatic feeder pressure adjustment | No | Yes | Yes |

| Automatic stitching head pressure adjustment | No | Yes | Yes |

| Customized small side folding | No | Yes | Yes |

| Folding part full servo control | No | Yes | Yes |

Main processed materials

Suitable for the following industries

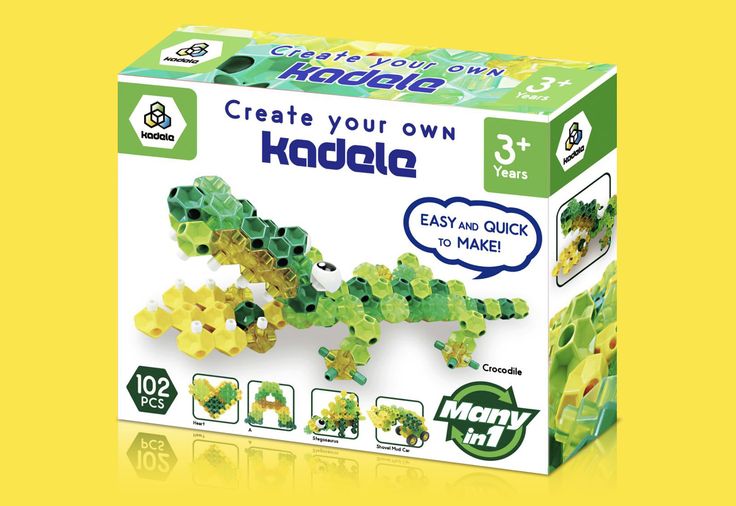

Example Of End Product

FengChi Service

Expert Service & Support

Interested in an automatic folder gluer stitcher?

Contact Form

Phone